Drag reducer as well as preparation method and application thereof

A technology of drag reducer and polyether polyol, which is applied in the direction of chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve the problems of difficult construction, easy gas channeling, strong filter loss, etc., and achieve The effect of good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

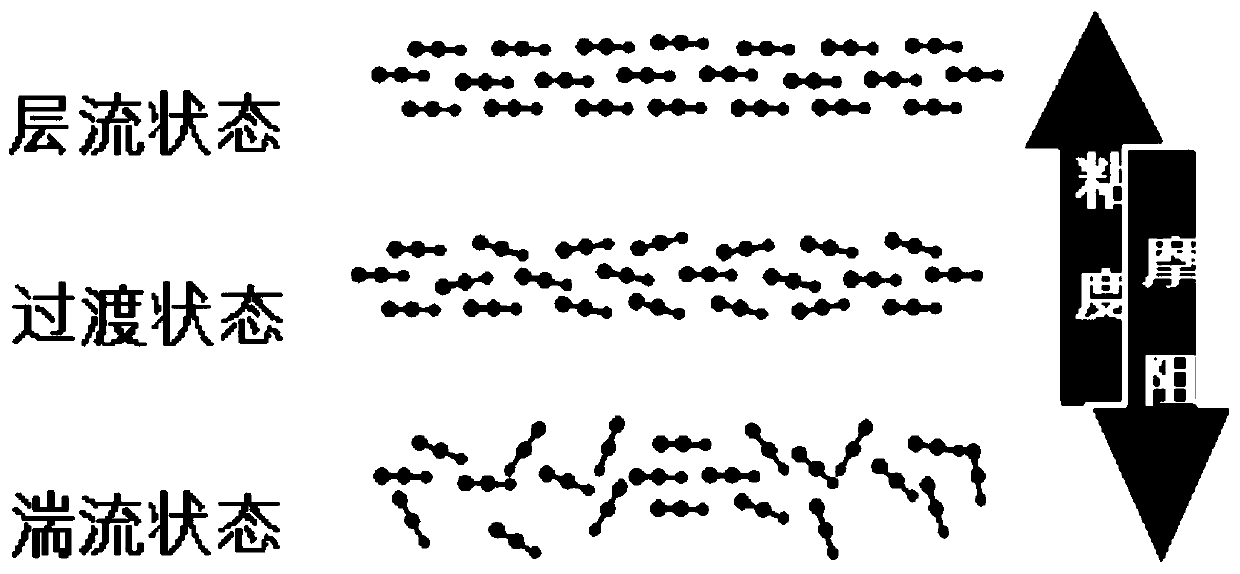

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a drag reducer for reducing resistance during liquid carbon dioxide fracturing, which is prepared through the following steps.

[0030] Preparation of polyether polyol: tetrahydrofuran and propylene oxide are catalyzed by ring-opening polymerization, and a tetrahydrofuran-propylene oxide copolymer diol with a molecular weight of 2000 is obtained through processes such as neutralization, water washing, dehydration and filtration.

[0031] The tetrahydrofuran-propylene oxide copolymer diol and polydimethylsiloxane with a viscosity of 8000 are mixed in a mass ratio of 5:2 to make them uniformly mixed.

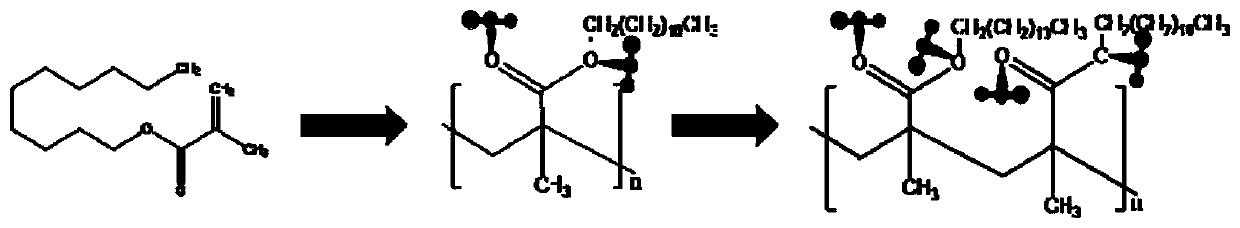

[0032] Prepare polylauryl methacrylate by following the following steps:

[0033] Dissolve 40 mL of lauryl methacrylate and 22 mL of divinylbenzene in 87 mL of N,N-dimethylformamide to obtain a mixed solution;

[0034] Dissolve 2g-4g of azobisisobutyronitrile in 38mL of absolute ethanol, add dropwise to the mixed solution under constant stirring, and heat to ...

Embodiment 2

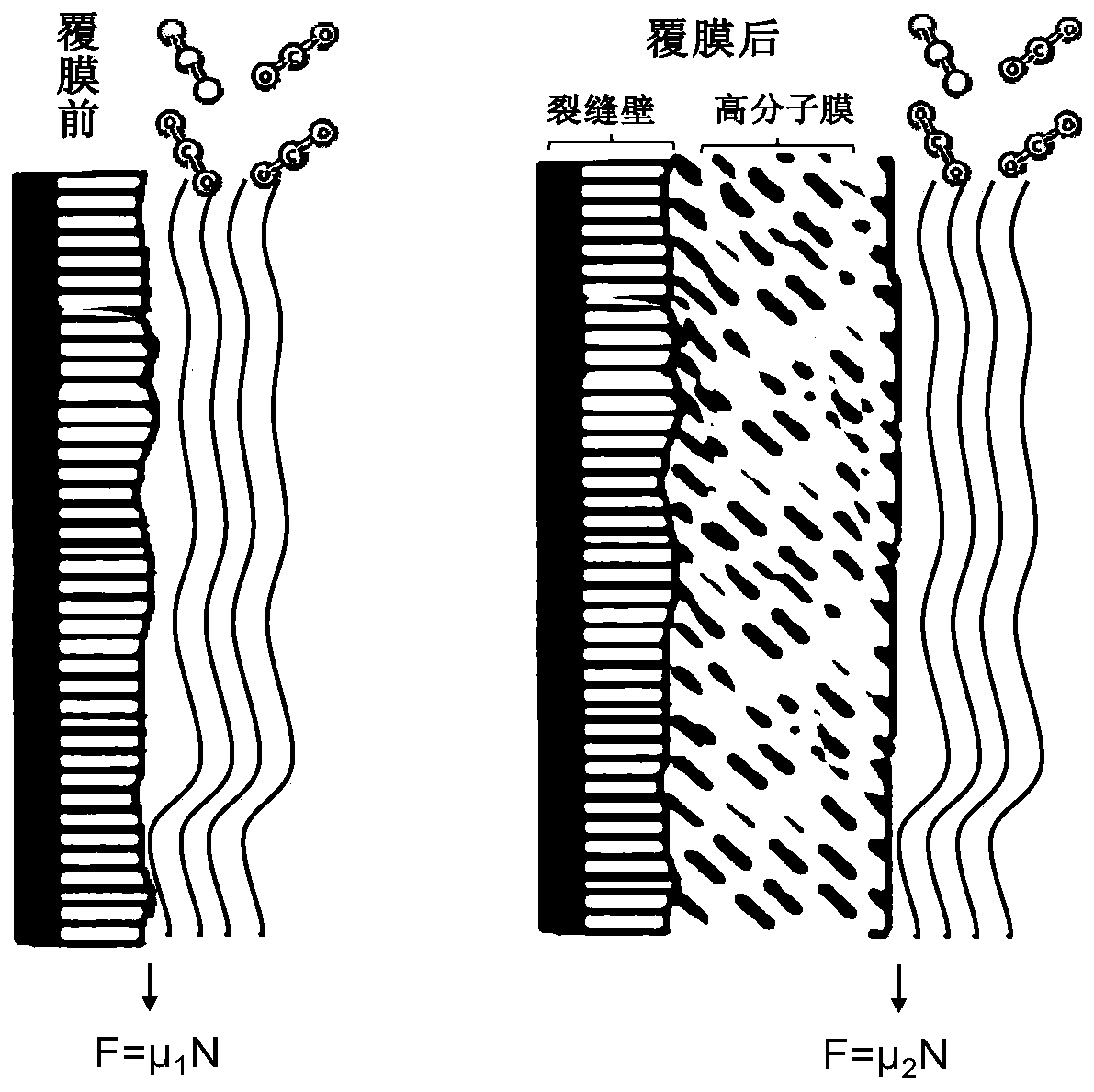

[0038] When performing carbon dioxide fracturing with water, the pressure difference between the inlet and outlet of the pipeline is 0.73Mpa. After adding the drag reducer of Example 1, the pressure difference between the inlet and the outlet is reduced to 0.27Mpa, and the drag reduction rate exceeds 55. %, reaching 63.1%.

[0039] This embodiment is used for oil and natural gas drilling operations. In the process of fracturing, the mass ratio of the added drag reducer to the mass ratio of carbon dioxide is 0.3%-0.5%, which can reduce the drag before introducing the carbon dioxide Add the agent to the pipeline. The drag reducer in supercritical CO 2 In the process of fracturing, the drag reduction rate can reach up to 63%, and it can be degraded by water / hydrocarbons, or can flow back quickly after being compressed, to prevent formation retention and cause damage. At the same time, drag reducers and liquid CO 2 It has good solubility and can form a uniform mixed solution within 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com