Inorganic anticorrosive paint and preparation method thereof

An anti-corrosion coating, inorganic technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of inability to effectively reduce the temperature of phosphate coatings, poor curing effect and low activity curing agent, and affect the overall performance of coatings, etc., to achieve Avoid the effects of being unable to form a film, no VOC release, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

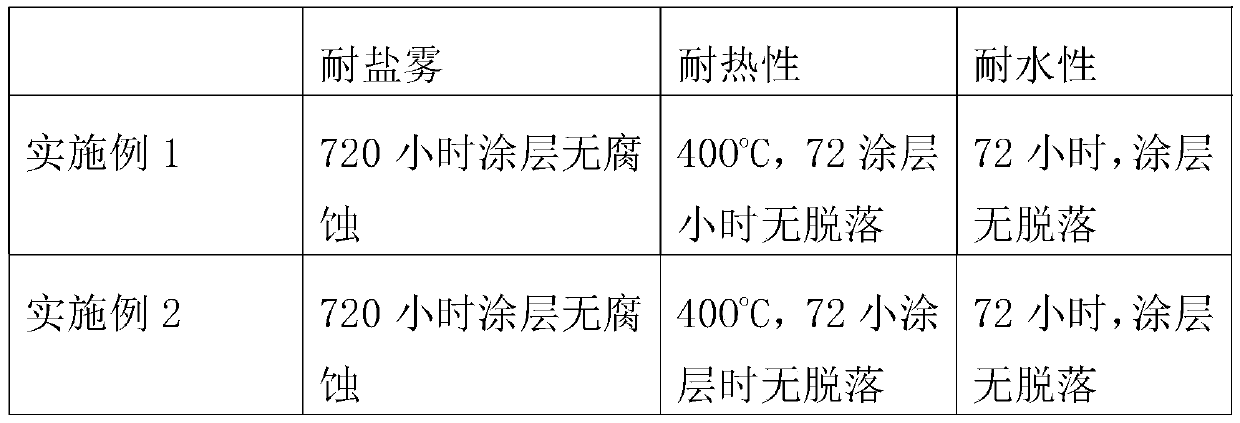

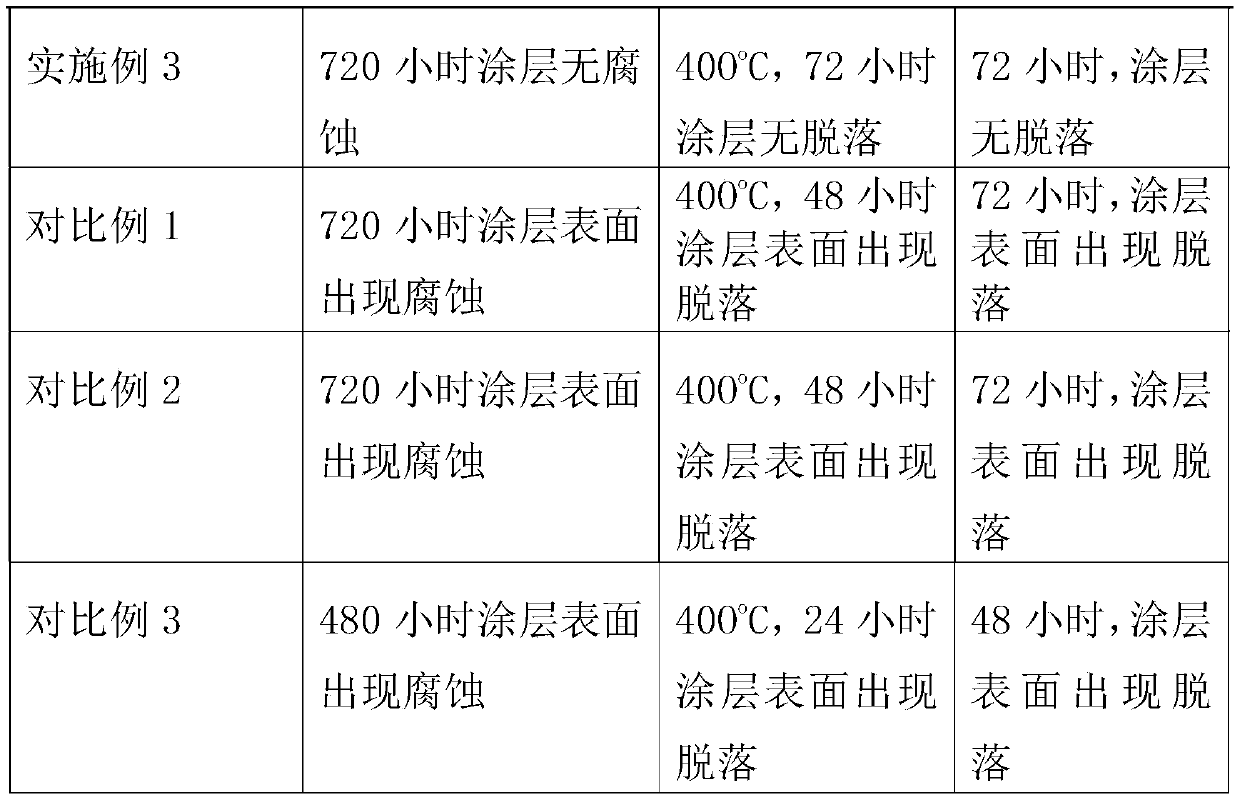

Examples

Embodiment 1

[0030] Embodiment 1 A kind of inorganic anticorrosion coating

[0031] Its preparation raw materials include by weight:

[0032] Aluminum dihydrogen phosphate adhesive: 80 parts;

[0033] Curing agent: 10 parts;

[0034] Auxiliary: 4 parts;

[0035] Filling: 4 parts;

[0036] Distilled water: 80 parts.

[0037] The aluminum dihydrogen phosphate adhesive is an aqueous solution of aluminum dihydrogen phosphate with a mass content of 25%.

[0038] The curing agent is a mixture of zinc oxide, magnesium oxide and nickel oxide, and the mass ratio of the zinc oxide, magnesium oxide and nickel oxide is 1:3:5.

[0039] The auxiliary agent is a mixture of borax and polydimethylsiloxane, and the mass ratio of borax to polydimethylsiloxane is 1:5.

[0040] The filler is a mixture of calcium aluminate, magnesium sulfate and nano molybdenum disulfide, and the mass ratio of calcium aluminate, magnesium sulfate and nano molybdenum disulfide is 10:6:1.

[0041] The average particle diam...

Embodiment 2

[0045] Embodiment 2 A kind of inorganic anticorrosion coating

[0046] Its preparation raw materials include by weight:

[0047] Aluminum dihydrogen phosphate adhesive: 90 parts;

[0048] Curing agent: 15 parts;

[0049] Auxiliary: 1 part;

[0050] Filling: 8 parts;

[0051] Distilled water: 90 parts.

[0052] The aluminum dihydrogen phosphate adhesive is an aqueous solution of aluminum dihydrogen phosphate with a mass content of 25%.

[0053] The curing agent is a mixture of zinc oxide, magnesium oxide and nickel oxide, and the mass ratio of zinc oxide, magnesium oxide and nickel oxide is 1:1:5.

[0054] The auxiliary agent is a mixture of borax and polydimethylsiloxane, and the mass ratio of borax to polydimethylsiloxane is 1:2.

[0055] The filler is a mixture of calcium aluminate, magnesium sulfate and nano molybdenum disulfide, and the mass ratio of calcium aluminate, magnesium sulfate and nano molybdenum disulfide is 10:6:3.

[0056] The average particle diameter ...

Embodiment 3

[0061] Embodiment 3 A kind of inorganic anticorrosion coating

[0062] Its preparation raw materials include by weight:

[0063] Aluminum dihydrogen phosphate adhesive: 85 parts;

[0064] Curing agent: 12 parts;

[0065] Auxiliary: 2 parts;

[0066] Filling: 6 parts;

[0067] Distilled water: 85 parts.

[0068] The aluminum dihydrogen phosphate adhesive is an aqueous solution of aluminum dihydrogen phosphate with a mass content of 25%.

[0069] The curing agent is a mixture of zinc oxide, magnesium oxide and nickel oxide, and the mass ratio of zinc oxide, magnesium oxide and nickel oxide is 1:2:5.

[0070] The auxiliary agent is a mixture of borax and polydimethylsiloxane, and the mass ratio of borax to polydimethylsiloxane is 1:4.

[0071]The filler is a mixture of calcium aluminate, magnesium sulfate and nano molybdenum disulfide, and the mass ratio of calcium aluminate, magnesium sulfate and nano molybdenum disulfide is 10:6:2.

[0072] The average particle diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com