Bridge-cut-off aluminum profile and preparation method thereof

A bridge-breaking aluminum profile technology, which is applied in the field of bridge-breaking aluminum profiles, can solve the problems of PVC heat insulation strips, poor thermal insulation effect, heat resistance and anti-aging performance, and shorten the service life of bridge-breaking aluminum profiles, so as to improve weather resistance Anti-aging ability, improving heat insulation effect, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

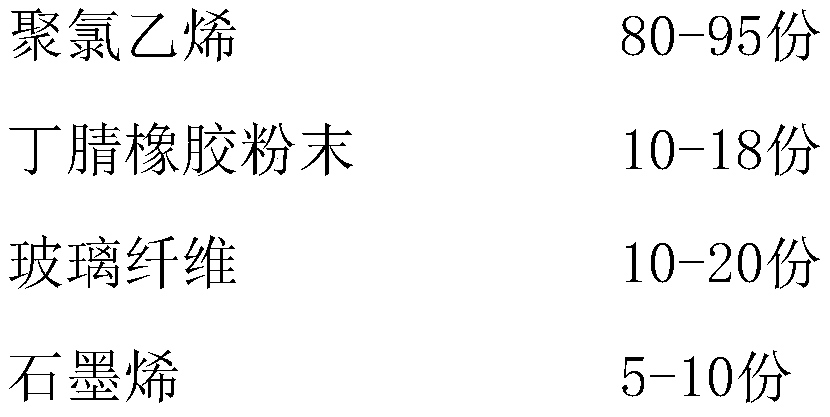

[0036] A bridge-breaking aluminum profile, comprising a first aluminum alloy component, a second aluminum alloy component, and a heat insulating strip connected between the first aluminum alloy component and the second aluminum alloy component; both sides of the heat insulating strip extend There are hook-shaped inserts, and the hook-shaped inserts on both sides of the heat insulation strip are respectively fixedly connected with the first aluminum alloy member and the second aluminum alloy member, and the heat insulation strip includes the following raw materials in parts by weight:

[0037]

[0038] The density of the polyvinyl chloride is 1.40g / cm 3 , the degree of polymerization is 800.

[0039] The content of acrylonitrile in the nitrile rubber powder is 21wt%, and the melt flow rate of the nitrile rubber powder is 2.0g / 10min.

[0040] The cross-linking agent is formed by mixing dicumyl peroxide and tetraethylthiuram disulfide in a weight ratio of 3:0.8.

[0041] The...

Embodiment 2

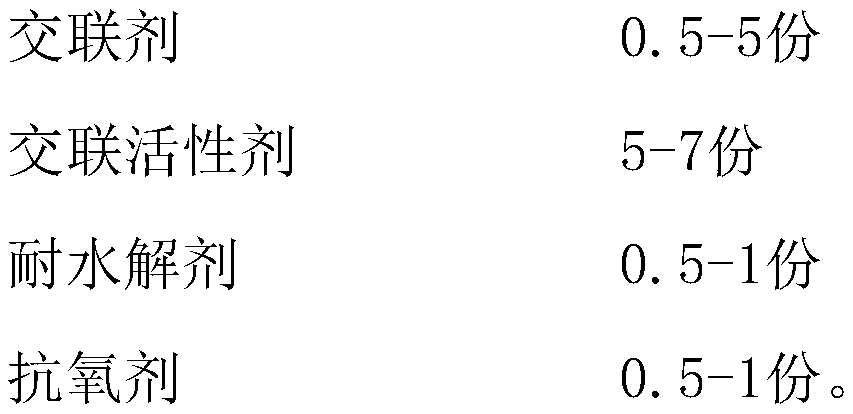

[0053] A bridge-breaking aluminum profile, comprising a first aluminum alloy component, a second aluminum alloy component, and a heat insulating strip connected between the first aluminum alloy component and the second aluminum alloy component; both sides of the heat insulating strip extend There are hook-shaped inserts, and the hook-shaped inserts on both sides of the heat insulation strip are respectively fixedly connected with the first aluminum alloy member and the second aluminum alloy member, and the heat insulation strip includes the following raw materials in parts by weight:

[0054]

[0055] The density of the polyvinyl chloride is 1.35g / cm 3 , the degree of polymerization is 750.

[0056] The content of acrylonitrile in the nitrile rubber powder is 18wt%, and the melt flow rate of the nitrile rubber powder is 1.7g / 10min.

[0057] The cross-linking agent is formed by mixing dicumyl peroxide and thiuram sulfide in a weight ratio of 3:0.5.

[0058] The thiuram sul...

Embodiment 3

[0071] A bridge-breaking aluminum profile, comprising a first aluminum alloy component, a second aluminum alloy component, and a heat insulating strip connected between the first aluminum alloy component and the second aluminum alloy component; both sides of the heat insulating strip extend There are hook-shaped inserts, and the hook-shaped inserts on both sides of the heat insulation strip are respectively fixedly connected with the first aluminum alloy member and the second aluminum alloy member, and the heat insulation strip includes the following raw materials in parts by weight:

[0072]

[0073] The density of the polyvinyl chloride is 1.50g / cm 3 , the degree of polymerization is 900.

[0074] The content of acrylonitrile in the nitrile rubber powder is 24wt%, and the melt flow rate of the nitrile rubber powder is 2.3g / 10min.

[0075] The crosslinking agent is formed by mixing dicumyl peroxide and dimethyldiphenylthiuram disulfide in a weight ratio of 3:1.

[0076] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com