A kind of preparation method of carbon fiber uniform electroplating copper layer

A technology for uniform electroplating and electroplating of copper layers, applied in the electrolytic process, electrolytic components, cells, etc., can solve the problems that affect the close bond between the coating and carbon fiber, the quality of the copper coating is general, and the process procedures are complex, and achieve low cost, coating The effect of good binding force and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

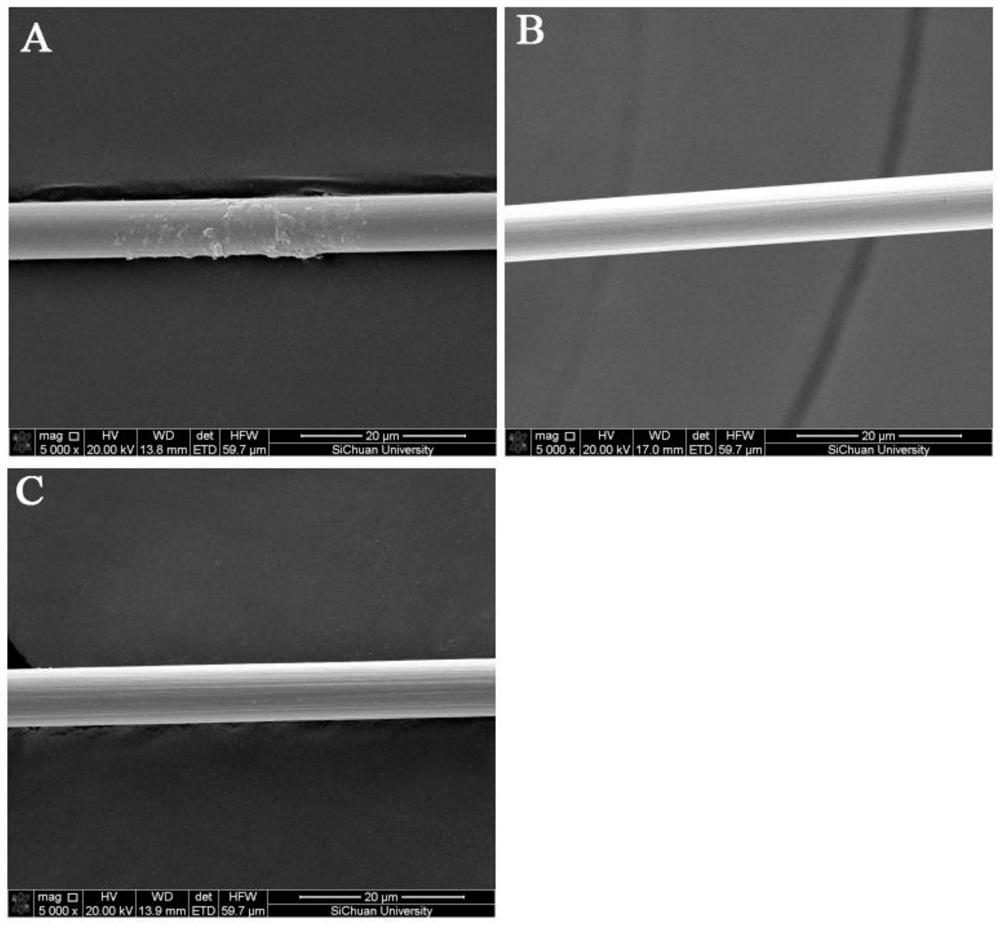

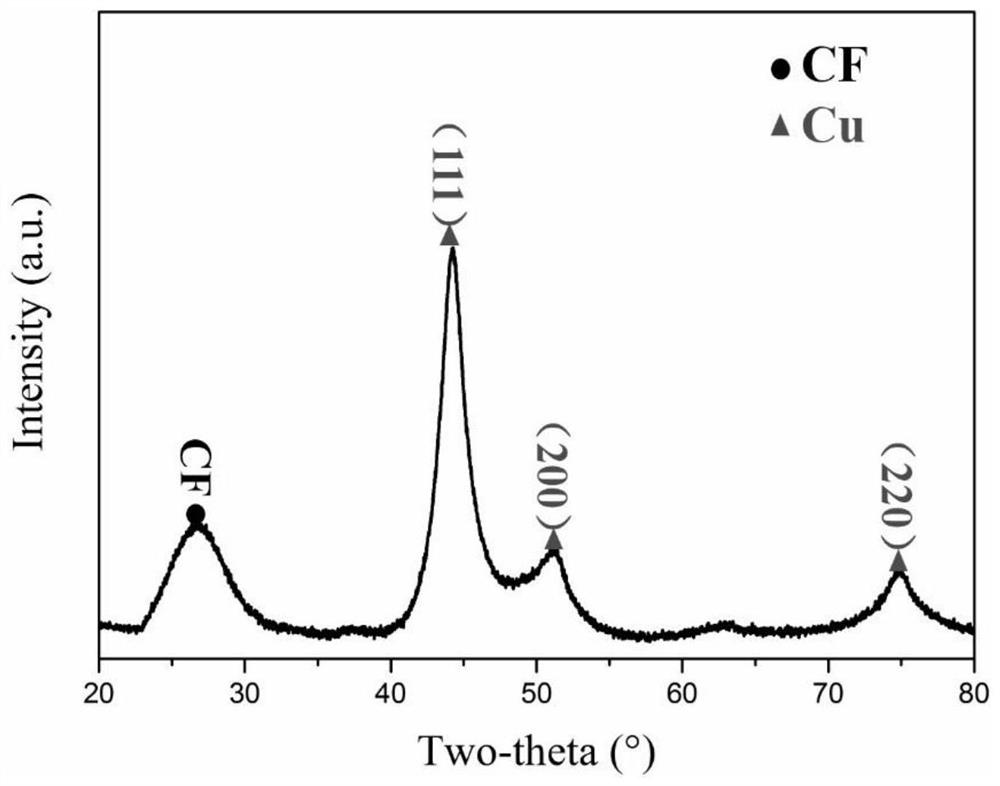

[0041] A method for preparing a carbon fiber uniform electroplated copper layer, comprising:

[0042] (1) Carbon fiber desizing: Cut the 12K (a bundle of fibers is 12000 carbon fiber monofilaments) carbon fiber tows with a monofilament diameter of 7 to 8 μm into short fiber tows with a length of 5 cm, and place them in acetone at 115 ° C. Reflux for 48 hours, then wash with acetone for 3 times, and dry in a blast oven at 50°C for 5 hours;

[0043] (2) Fix the desizing-treated carbon fibers on the metal support by physical methods to ensure that the carbon fibers are dispersed as much as possible;

[0044] (3) Configuration of electroplating solution: 100.00g CuSO 4 ·5H 2 O, 20.00g C 4 h 4 o 6 KNa·4H 2 O, 180.00gC 6 h 5 Na 3 o 7 2H 2 O, 24.00g KNO 3 Dissolve 0.10g of polyethylene glycol (PEG) in 1L of ultrapure water, stir evenly at room temperature, then add 0.27g of NaCl, the composition of the electroplating solution is shown in Table 1 below, and continue to sti...

Embodiment 2

[0050] A preparation method of carbon fiber uniform electroplated copper layer is basically the same as the method of embodiment 1, the difference is:

[0051] In step (1), the temperature of acetone reflux is 100°C; the drying temperature is 40°C;

[0052] In step (4), the distance between cathode and anode is 4cm, and the current density is kept at 0.80mA / cm 2 , the voltage is 1.5V, electroplating is 90min; the drying temperature is 40°C.

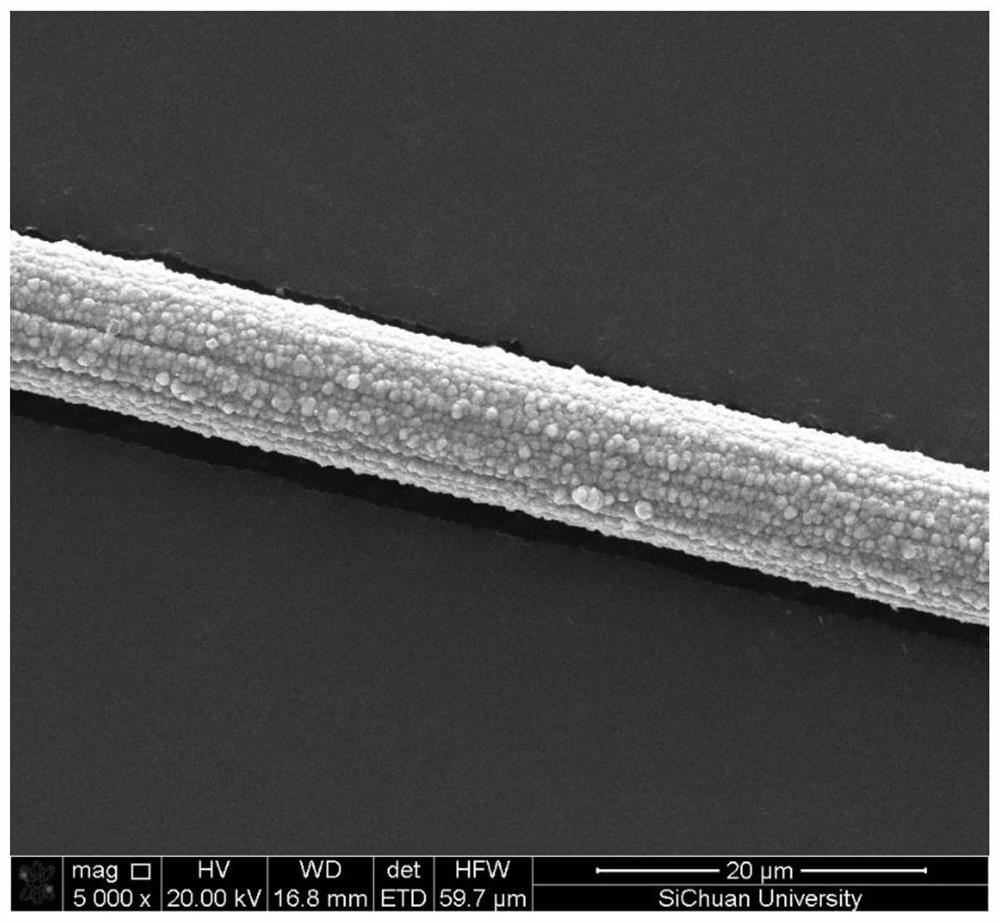

[0053] Such as Figure 5 Shown is the scanning electron microscope (SEM) image of the topography of the copper layer on the surface of the carbon fiber in Example 2 of the present invention. Compared with Example 1, the final attachments on the surface of the carbon fiber are the same copper grains, and the material of the copper grains There is no difference in the structure itself, but there are small differences in the amount of adhesion and surface morphology, but the copper grains on the surface of the carbon fiber are very uniform...

Embodiment 3

[0056] A preparation method of carbon fiber uniform electroplated copper layer is basically the same as the method of embodiment 1, the difference is:

[0057] In step (1), the temperature of acetone reflux is 120°C; the drying temperature is 60°C;

[0058] In step (4), the distance between cathode and anode is 10cm, and the current density is kept at 1.00mA / cm 2 , the voltage is 3.0V, electroplating is 60min; the drying temperature is 60°C.

[0059] Such as Image 6 Shown is the scanning electron microscope (SEM) image of the topography of the copper layer on the surface of the carbon fiber in Example 3 of the present invention. Compared with Example 1, the final attachments on the surface of the carbon fiber are the same copper grains, and the material of the copper grains There is no difference in the structure itself, but there are small differences in the amount of adhesion and surface morphology, but the copper grains on the surface of the carbon fiber are very uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com