Multiple trigger photoresist compositions and method

A photoresist and composition technology, applied in the multi-trigger photoresist process field, can solve the problems of reduced exposure latitude, poor resolution, reduced sensitivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

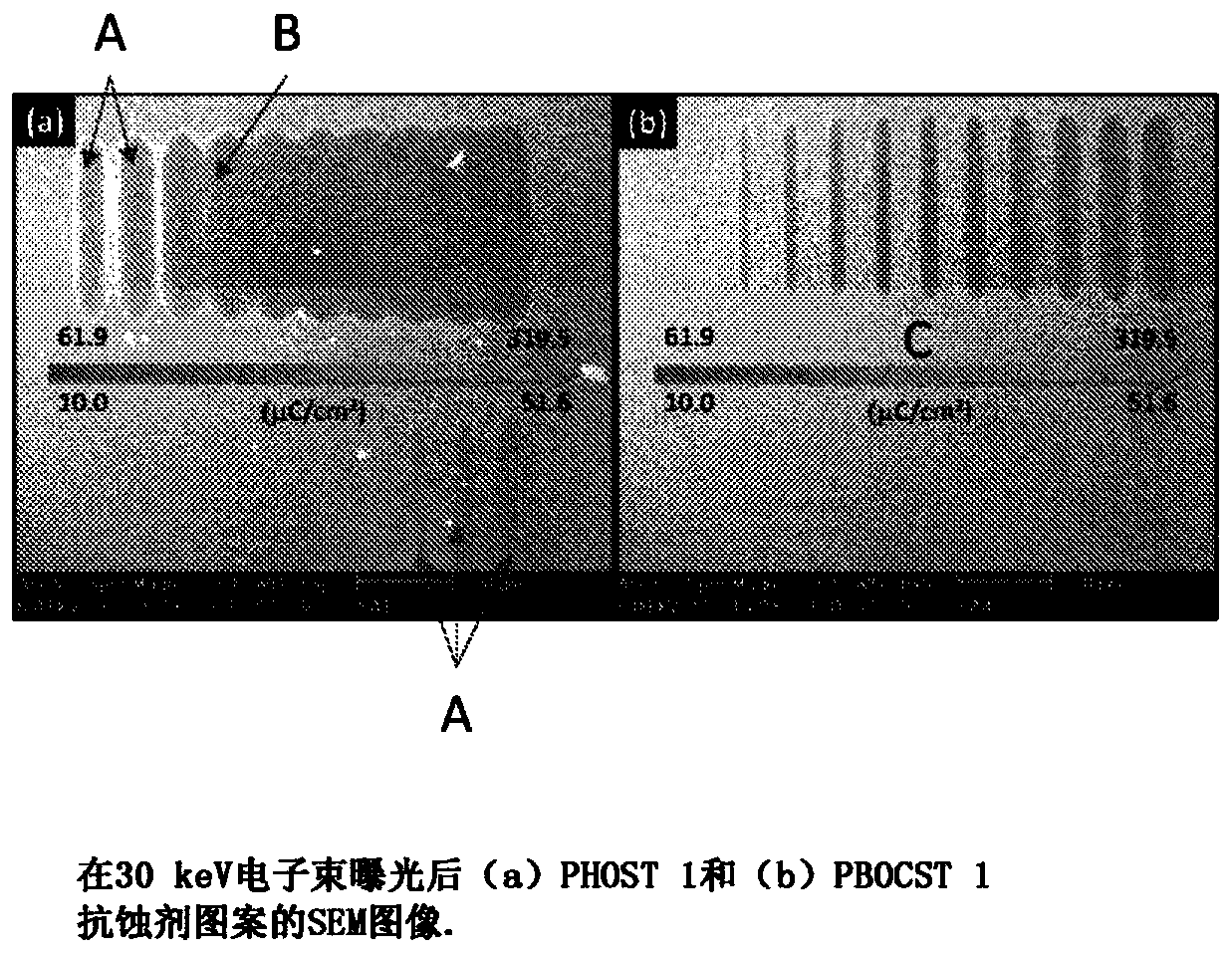

[0064] HMMM used in the examples is hexamethoxymethylmelamine (Sigma Aldrich), PHOST is polyhydroxystyrene (MW = about 2500) synthesized at Warwick University, PBOCST is poly(4-tert-butyl) synthesized at Warwick University oxycarbonyloxystyrene) (MW = about 2500), PGEF is poly((phenylglycidyl ether)-co-formaldehyde) (Huntsman Chemical), PAG is triphenylsulfonium hexafluoroantimonate (Midori Kagaku) .

[0065] PHOST 1: Add 0.50 g of HMMM acid-activated crosslinker, 0.50 g of PHOST and 0.25 g of PAG into 100 mL of propylene glycol monomethyl ether (PGME), and stir at room temperature for 1 hour.

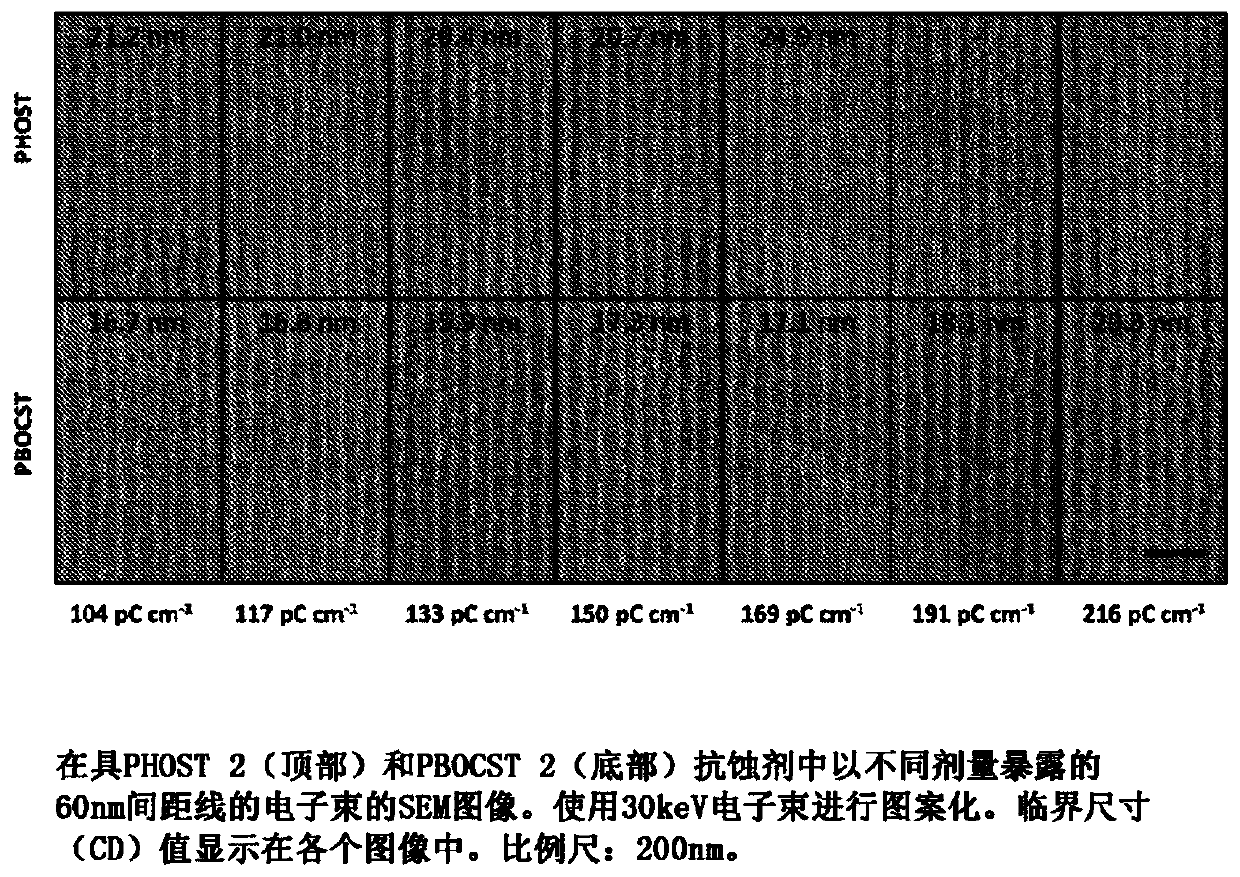

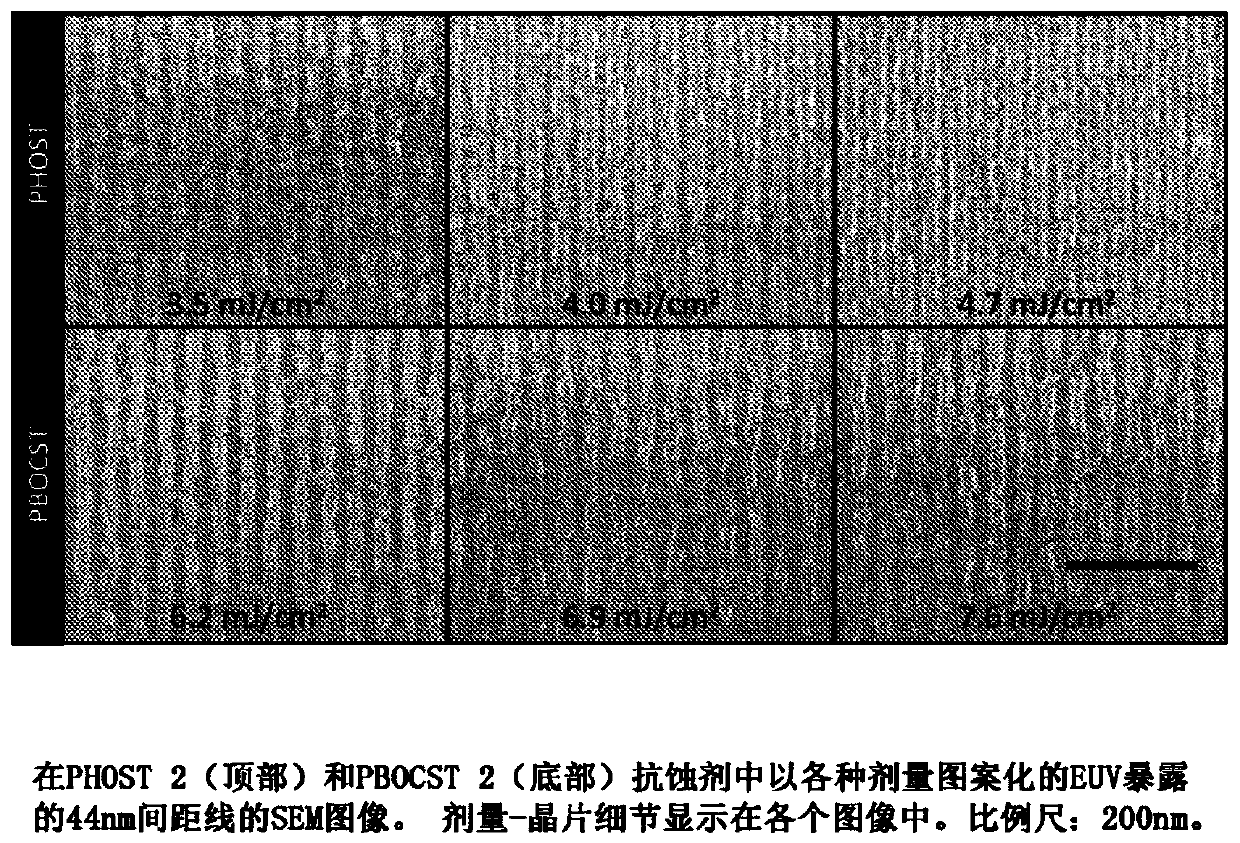

[0066] PHOST 2: Add 0.50 g PGEF acid-activated crosslinker, 0.25 g PHOST and 0.25 g PAG to 100 mL propylene glycol monomethyl ether (PGME), and stir at room temperature for 1 hour.

[0067] PBOCST 1: Replace PHOST with PHOCST, repeat PHOST 1.

[0068] PBOCST 2: Replace HMMM with PGEF, repeat PHOST 2.

[0069] Silicon chips cut from 100 mm wafers (Rockwood Electronic Materials, n-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com