Multi-component solid electrolyte and preparation method and application thereof

A solid electrolyte, multi-component technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems that the blends cannot achieve molecular mutual compatibility, and it is difficult to mix uniformly to prepare solid electrolytes, and achieve good uniformity. , the effect of high mechanical strength and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

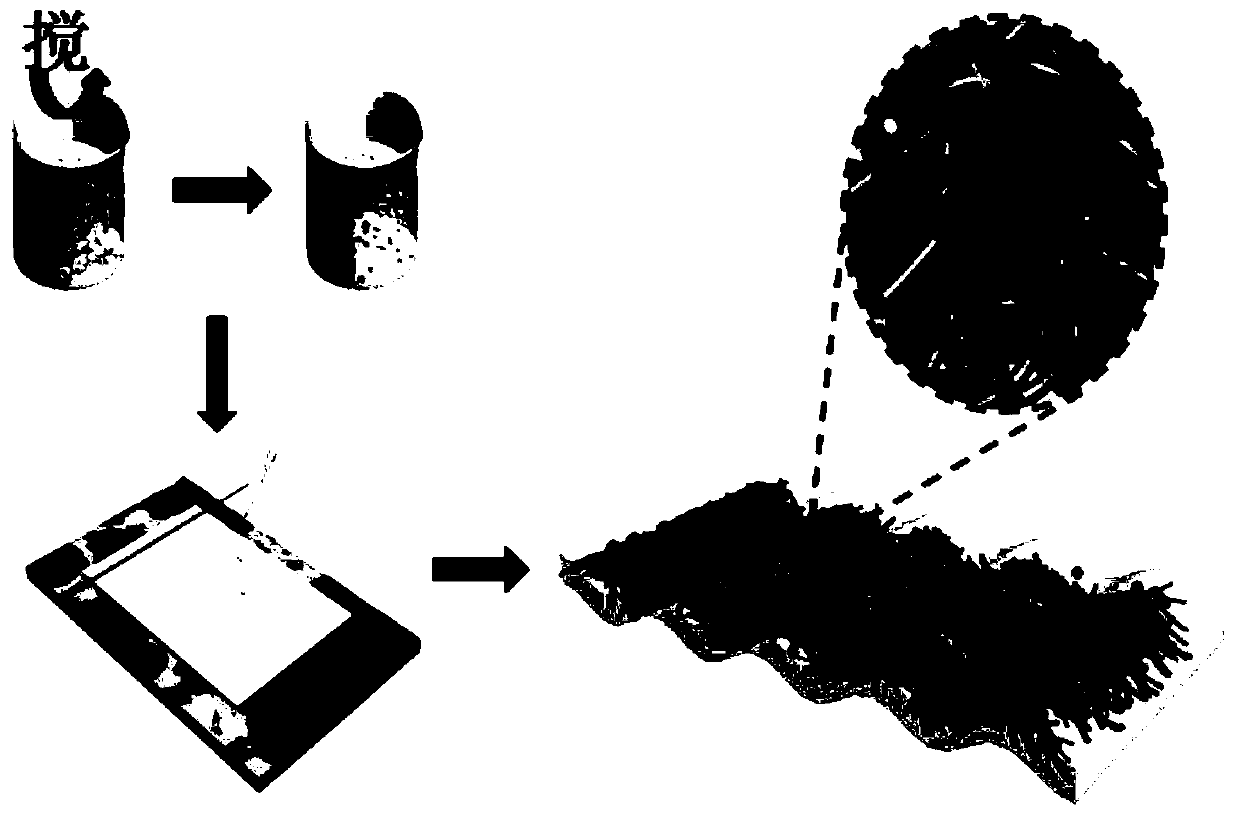

[0049] A kind of multi-component solid electrolyte, its specific preparation method is as follows (see figure 1 ):

[0050] Polyethylene oxide (PEO) has high ionic conductivity at 60°C, but its low mechanical strength, poor heat resistance, and narrow electrochemical window limit its further application. Polyvinylidene fluoride-hexafluoropropylene [P(VDF-HFP)] has good mechanical strength and high temperature resistance, and has an electrochemical window exceeding 4.5V. It is highly feasible to use P(VDF-HFP) to modify PEO, which can effectively improve the mechanical strength, heat resistance and electrochemical window of PEO.

[0051] (1) The required raw materials polyethylene oxide (PEO), polyvinylidene fluoride-hexafluoropropylene [P(VDF-HFP)], lithium bistrifluoromethanesulfonylimide (LiTFSI), lithium lanthanum zirconium oxide (LLZTO) ceramic powder was placed in a vacuum oven and dried under vacuum at 50°C for 12h.

[0052] (2) Weigh 0.6g of PEO with a weight average...

Embodiment 2

[0070] A multi-component solid electrolyte, its specific preparation method is as follows:

[0071] (1) Weigh 0.5g polyacrylonitrile, 0.5g polyethylene oxide, 0.6g LiFSI and 0.3g polyamide fiber.

[0072] (2) Weigh 8 mL of acetonitrile and 8 mL of dimethylformamide, and stir magnetically for 5 minutes.

[0073] (3) Add (1) Chinese medicine into (2) solution, heat at 60° C., stir for 6 hours, and the solution becomes a homogeneous solution.

[0074] (4) Pour the above homogeneous solution into a polytetrafluoroethylene mold, and control the thickness of the solid electrolyte by controlling the amount and solid content of the solution.

[0075] (5) After standing still for 6 hours, the surface solution was volatilized and dried, heated in a vacuum oven at 60° C., and dynamically evacuated for 12 hours to obtain a solid electrolyte.

[0076] Figure 14 The scanning electron microscope image of the solid electrolyte prepared for this example shows that the blended solid electro...

Embodiment 3

[0079] A multi-component solid electrolyte, its specific preparation method is as follows:

[0080] (1) Weigh 0.3g of polyacrylonitrile (PAN), 0.7g of polyvinylidene fluoride (PVDF), 0.5g of sodium bistrifluorosulfonate and 0.2g of glass fiber.

[0081] (2) Considering that PAN is dissolved in acetone and PVDF is dissolved in tetrahydrofuran, a mixed solvent system of acetone and tetrahydrofuran is used in this example to prepare a blended solid electrolyte membrane. Weigh 4.8mL acetone and 11.2mL tetrahydrofuran, and magnetically stir 5 minutes.

[0082] (3) Add (1) Chinese medicine into (2) solution, heat at 60°C, and stir for 6 hours.

[0083] (4) Pour the above homogeneous solution into a polytetrafluoroethylene mold.

[0084] (5) After standing still for 6 hours, put it into a vacuum oven, heat at 60° C., and apply a dynamic vacuum for 12 hours to obtain a solid electrolyte that can be applied to a sodium-ion secondary battery.

[0085] Figure 16 From the scanning el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com