Antibacterial composite fiber and preparation method thereof

A composite fiber and fiber technology, which is applied in fiber treatment, fiber mixing, fiber chemical characteristics, etc., can solve the problems of poor antibacterial and mildew-proof effect of far-infrared composite fiber, affecting the use effect of composite fiber, and reducing far-infrared performance. Improve the antistatic performance, prolong the antibacterial effect, and improve the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

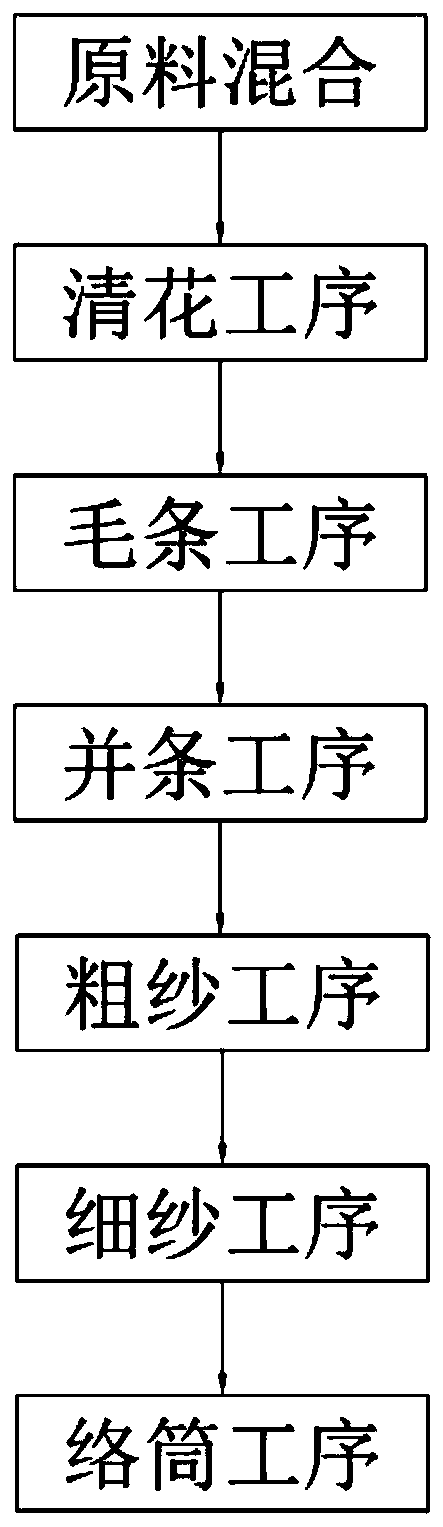

Method used

Image

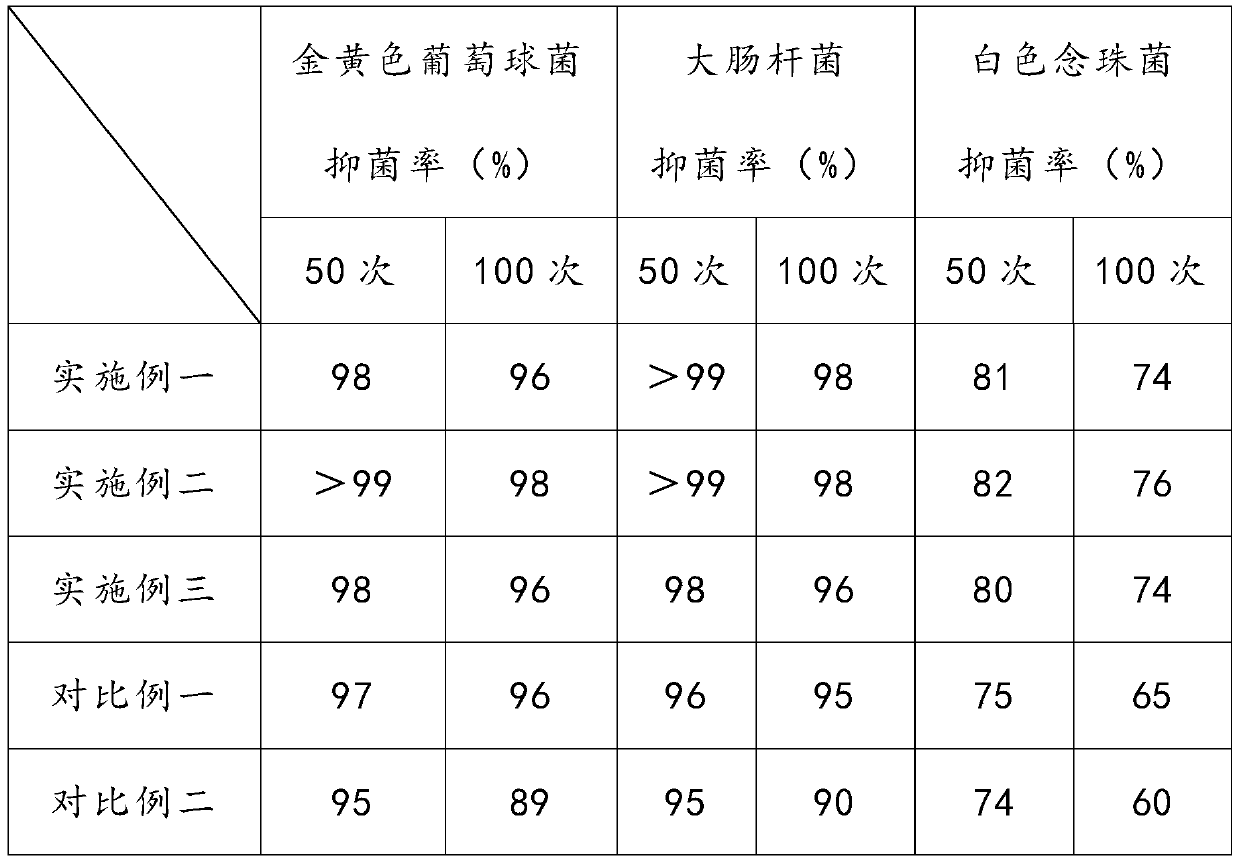

Examples

Embodiment 1

[0045] An antibacterial composite fiber, comprising the following components by weight:

[0046] Antibacterial spinning polyester 18 parts;

[0047] Viscose fiber 26 parts;

[0048] 45 parts of cotton;

[0049] The antibacterial spun polyester is the modified spun polyester obtained by pretreatment, and the pretreatment method comprises the following steps:

[0050] Step 1. Mix meteorites and zinc oxide of equal mass to obtain mixed additives;

[0051] Step 2, micronize the mixed additives by using nanotechnology, and grind them into a 400nm nanoscale powder ultrafine particle mixture;

[0052] Step 3, the mixture obtained in step 2 and polyester and as additives and the TAF dispersant of 0.1 part by weight and the polyethylene oxide of 0.1 part by weight are made into modified spinning by blending and spinning Polyester, the mixing ratio of the mixture is 6%.

[0053] Viscose fibers include silica viscose fibers and spar viscose fibers at a ratio of 1:1 by weight;

[00...

Embodiment 2

[0072] An antibacterial composite fiber, comprising the following components by weight:

[0073] Antibacterial spinning polyester 20 parts;

[0074] 30 parts of viscose fiber;

[0075] 50 parts of cotton;

[0076] The antibacterial spun polyester is the modified spun polyester obtained by pretreatment, and the pretreatment method comprises the following steps:

[0077] Step 1. Mix meteorites and zinc oxide of equal mass to obtain mixed additives;

[0078] Step 2, micronize the mixed additives by using nanotechnology, and grind them into a 400nm nanoscale powder ultrafine particle mixture;

[0079] Step 3, the mixture obtained in step 2 and polyester and as additives and the TAF dispersant of 0.1 part by weight and the polyethylene oxide of 0.1 part by weight are made into modified spinning by blending and spinning The mixing ratio of polyester and meteorite is 10%.

[0080] Viscose fibers include silica viscose fibers and spar viscose fibers at a ratio of 1:1 by weight; ...

Embodiment 3

[0099] An antibacterial composite fiber, comprising the following components by weight:

[0100] Antibacterial spinning polyester 22 parts;

[0101] Viscose fiber 34 parts;

[0102] 55 parts of cotton;

[0103] The antibacterial spun polyester is the modified spun polyester obtained by pretreatment, and the pretreatment method comprises the following steps:

[0104] Step 1. Mix meteorites and zinc oxide of equal mass to obtain mixed additives;

[0105] Step 2, micronize the mixed additives by using nanotechnology, and grind them into a 400nm nanoscale powder ultrafine particle mixture;

[0106] Step 3, the mixture obtained in step 2 and polyester and as additives and the TAF dispersant of 0.1 part by weight and the polyethylene oxide of 0.1 part by weight are made into modified spinning by blending and spinning The mixing ratio of polyester and meteorite is 14%.

[0107] Viscose fibers include silica viscose fibers and spar viscose fibers at a ratio of 1:1 by weight;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com