Process method for producing rare earth eutectic phosphor by guided mode method

A process method and phosphor technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of LED color temperature and other parameters inconsistency, waste heat, reduced service life and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

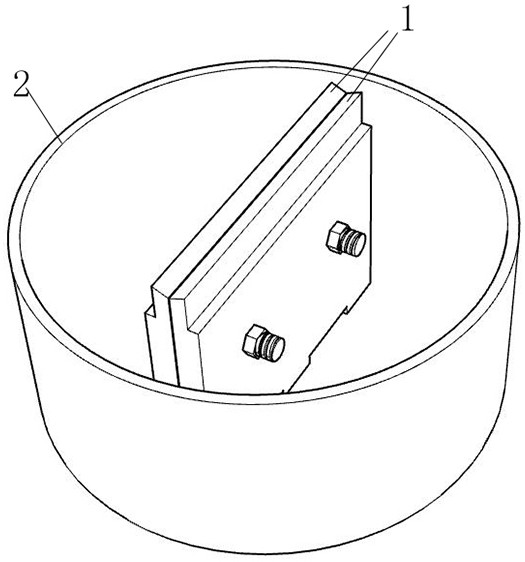

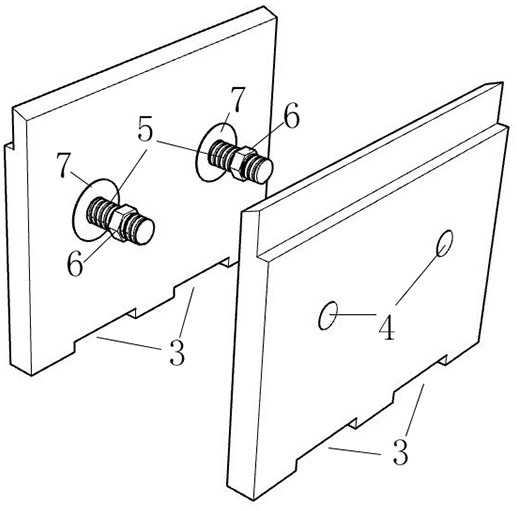

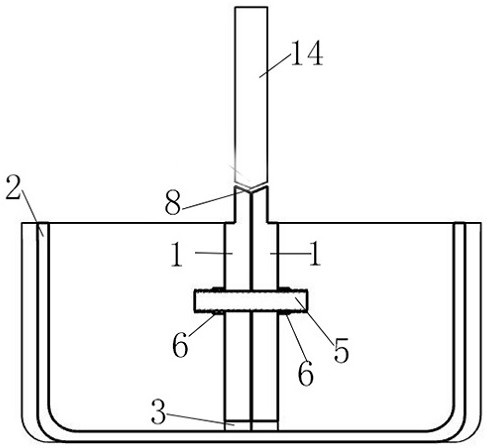

[0081] The preparation of the rare earth eutectic phosphor developed by our unit adopts the guided mode method; it is not enough to only use the existing crucible; after repeated research and experiments, the scientific research personnel of our unit added a set of heating to the existing furnace body 9 The heat preservation device 21 is used to ensure the smooth production of the rare earth eutectic phosphor.

[0082] Such as Figure 5-12 As shown, the above-mentioned heating and heat preservation device 21 includes the above-mentioned induction heating coil 12 supported and fixed by the coil support 11. A high-temperature-resistant base 22 is placed directly below the coil 12. The base 22 is cylindrical, and the upper surface should be horizontal. This unit uses cylindrical refractory bricks as the base 22. Of course, other refractory materials can also be used, such as alumina bricks; the upper surface of the base 22 is a cylindrical quartz barrel 23, and the quartz barrel ...

Embodiment 1

[0125] Weigh Al at a molar ratio of 81:18.5:0.1 2 o 3 , Y 2 o 3 , CeO 3 ; Other steps are the same as above to prepare a rare earth eutectic phosphor.

[0126] The comparison between the rare earth eutectic phosphor prepared by the present invention and the existing blue light chip+Ce:YAG phosphor will be described below.

[0127] Such as Figure 15 As shown, the right side is the phosphor powder, and the left side is the rare earth eutectic phosphor prepared by the present invention; the two crystal phases constituting the eutectic in the rare earth eutectic phosphor are YAG and Al respectively 2 o 3 , these two materials have good light transmission and close refractive index, which greatly reduces the total reflection loss of the interface. Since there is no problem of additional preparation of powder and glue, the following two problems existing in the prior art are avoided:

[0128] 1) The refractive index (1.83) of Ce:YAG phosphor particles is quite different from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com