A kind of boiler coking inhibitor and preparation method thereof

A technology for coking inhibitors and boilers, applied in fuel additives, lighting and heating equipment, solid fuels, etc., can solve the problems of poor suppression effect, failure to achieve, and damage to the combination of slag and coke ash, and achieve easy flowability and easy Effect of cleaning and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

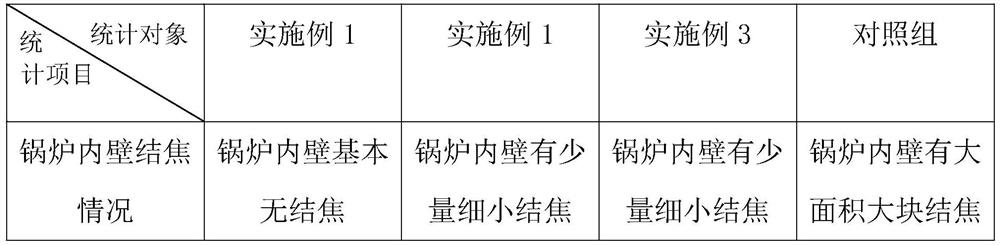

Embodiment 1

[0029] A boiler coking inhibitor, the raw materials of which include by weight: 25 parts of nitrate compound, 7 parts of borax, 15 parts of heavy oil, 7 parts of boric acid, 4 parts of active rare earth metal powder, 4 parts of modified nano-alumina, combustion-supporting 4 parts of thermal conductive dispersant, 4 parts of loosening agent and 4 parts of corrosion inhibitor. The nitrate compound is a composition of aluminum nitrate, copper nitrate, ammonium nitrate, potassium nitrate, sodium nitrate, cerium nitrate and barium nitrate. The agent is potassium permanganate, potassium chlorate, a combination of potassium perchlorate and manganese oxide, the active rare earth metal powder is a combination of samarium powder and lanthanum powder, the loosening agent is sodium bicarbonate, and the corrosion inhibitor is benzotriazole. The dispersant is a combination of magnesium oxide, calcium oxide, aluminum oxide and silicon dioxide.

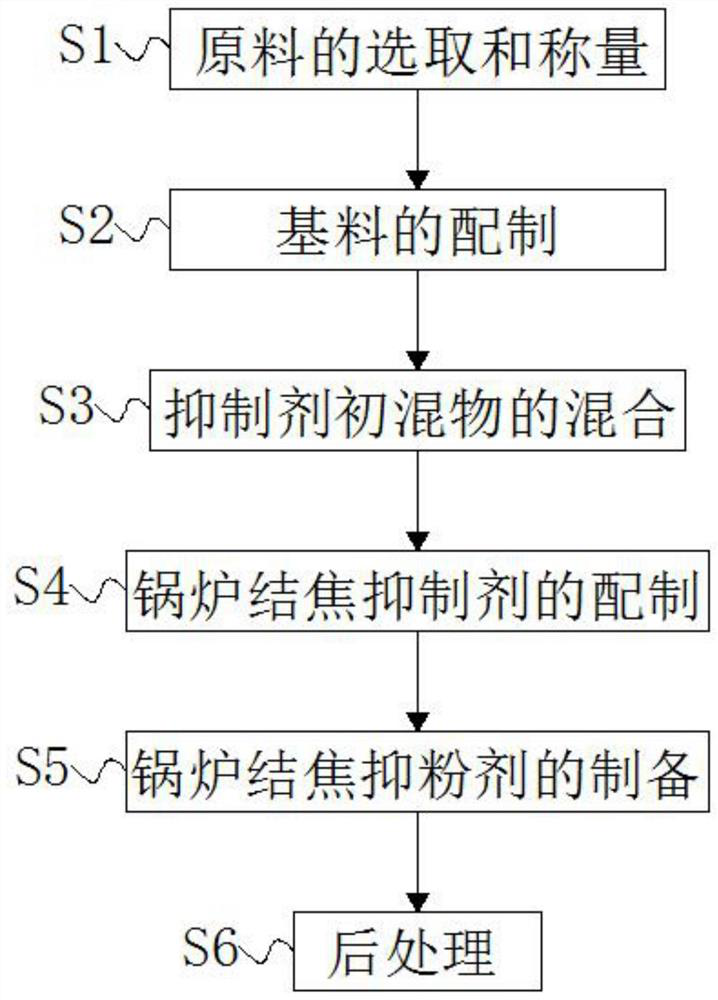

[0030] A preparation method of a boiler coking...

Embodiment 2

[0038] A boiler coking inhibitor, the raw materials of which include by weight: 20 parts of nitrate compound, 5 parts of borax, 10 parts of heavy oil, 5 parts of boric acid, 5 parts of active rare earth metal powder, 5 parts of modified nano-alumina, combustion-supporting 5 parts of thermal conductive dispersant, 5 parts of loosening agent and 5 parts of corrosion inhibitor, the nitrate compound is aluminum nitrate, the combustion aid is potassium permanganate, the active rare earth metal powder is samarium powder, and the loosening agent is ammonium bicarbonate , the corrosion inhibitor is mercaptobenzothiazole, and the thermally conductive dispersant is magnesium oxide.

[0039] A preparation method of a boiler coking inhibitor, specifically comprising the following steps:

[0040] S1. Selection and weighing of raw materials: First, measure the required weight ratio of nitrate compound, borax, heavy oil, boric acid, active rare earth metal powder, modified nano-alumina, comb...

Embodiment 3

[0047] A boiler coking inhibitor, the raw materials of which include by weight: 30 parts of nitrate compound, 10 parts of borax, 20 parts of heavy oil, 10 parts of boric acid, 3 parts of active rare earth metal powder, 3 parts of modified nano-alumina, combustion-supporting 3 parts of thermal conductive dispersant, 3 parts of loosening agent and 3 parts of corrosion inhibitor, the nitrate compound is barium nitrate, the combustion aid is manganese oxide, the active rare earth metal powder is lanthanum powder, the loosening agent is sodium bicarbonate, and the slowing agent is sodium bicarbonate. The etchant is tolyltriazole, and the thermally conductive dispersant is silicon dioxide.

[0048] A preparation method of a boiler coking inhibitor, specifically comprising the following steps:

[0049] S1. Selection and weighing of raw materials: First, measure the required weight ratio of nitrate compound, borax, heavy oil, boric acid, active rare earth metal powder, modified nano-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com