Environment-friendly, antistatic, heat-resistant and wear-resistant ABS material and preparation method thereof

An ABS material, antistatic technology, applied in the field of modified plastics, can solve the problems of easy dust absorption, low environmental protection level, general heat resistance and wear resistance, etc., to reduce friction coefficient, ensure heat resistance, and improve wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

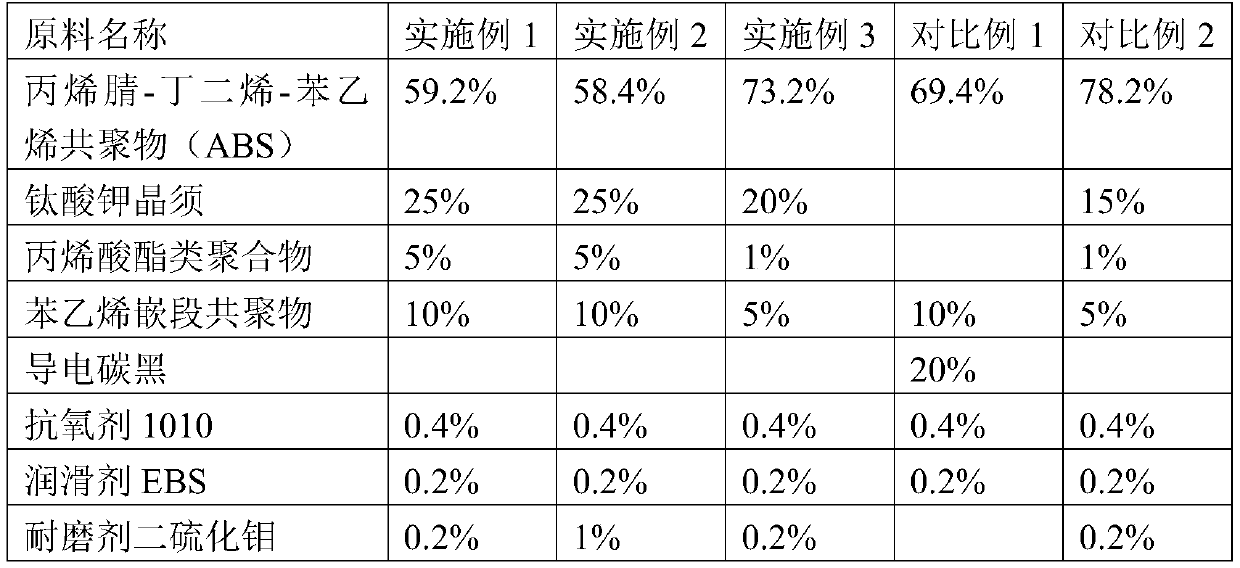

Embodiment 1-3 and comparative example 2

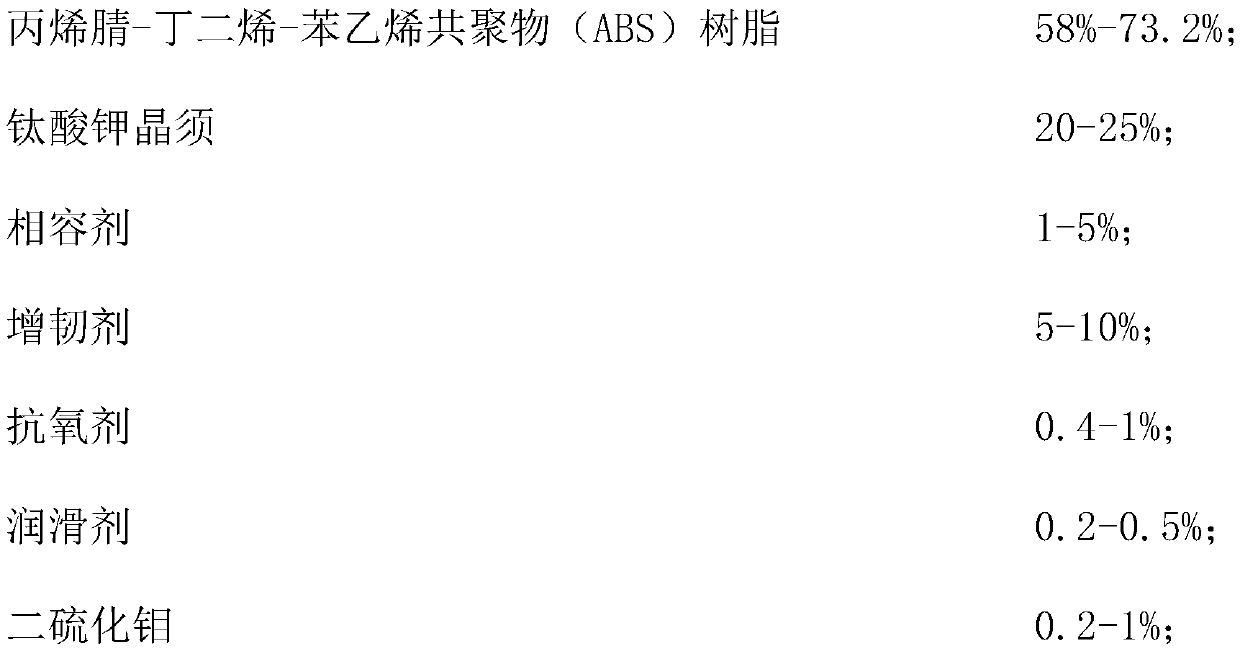

[0037] A kind of environmental protection, antistatic, heat-resistant, wear-resistant ABS material, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0038] Step 1: Take acrylonitrile-butadiene-styrene copolymer (ABS) resin, acrylate polymer, styrene block copolymer, antioxidant 1010, lubricant EBS, wear-resistant agent 2 by weight percentage Molybdenum sulfide, and mix it in a high-speed mixer for 1-3min at a high speed, and mix evenly to obtain a premix;

[0039] Step 2: Feed the uniformly mixed premix into the extruder from the main feeding port of the extruder, and feed potassium titanate whiskers into the screw barrel of the extruder from the side feeding port of the extruder. Melt, extrude, and granulate in an extruder to obtain the environmentally friendly, antistatic, heat-resistant, wear-resistant ABS material of the present invention;

[0040] The processing conditions for melt extrusion of the extruder in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com