Nano composite material based on enzyme degradation enhanced photo-thermal removal of bacterial biofilms, and preparation method and application of nano composite material

A nanocomposite material and bacterial biofilm technology, applied in the field of nanocomposite materials and its preparation, can solve the problems of lack of biofilm targeting ability, large side effects, poor curative effect, etc., and achieve the problem of not easy bacterial resistance, low potential toxicity, The effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] MnO 2 - Preparation of amylase-PEG-ICG (MAPI) nanosheets

[0031] 1. MnO 2 Preparation of nanosheets

[0032] Take 0.6 g MnCl 2 4H 2 O (3 mM) crystals in a 50 mL reaction flask, add 10 mL H 2 O. Take 12 mL of TMA OH (tetramethylammonium hydroxide, 12 mM) solution, add 2 mL of H 2 o 2 (30%wt), and diluted with water to 20 mL. The above two solutions were mixed, the solution turned from colorless and transparent to brown, and the reaction was stirred on a magnetic stirrer for 12 h. After the reaction, the solution was taken out, centrifuged at 3000 rpm for 10 min, and the lower layer of precipitate was taken. Wash with ethanol and water three times respectively under the above centrifugation conditions, and finally add aqueous solution to dilute to 30 mL. Take 10 mL of cleaned MnO 2 , add 20 mL H 2 O, use a probe sonicator to sonicate for 10 h (power: 40%, time interval: 5 s), centrifuge the obtained solution at 12000 rpm for 45 min, discard the lower sediment...

Embodiment 2

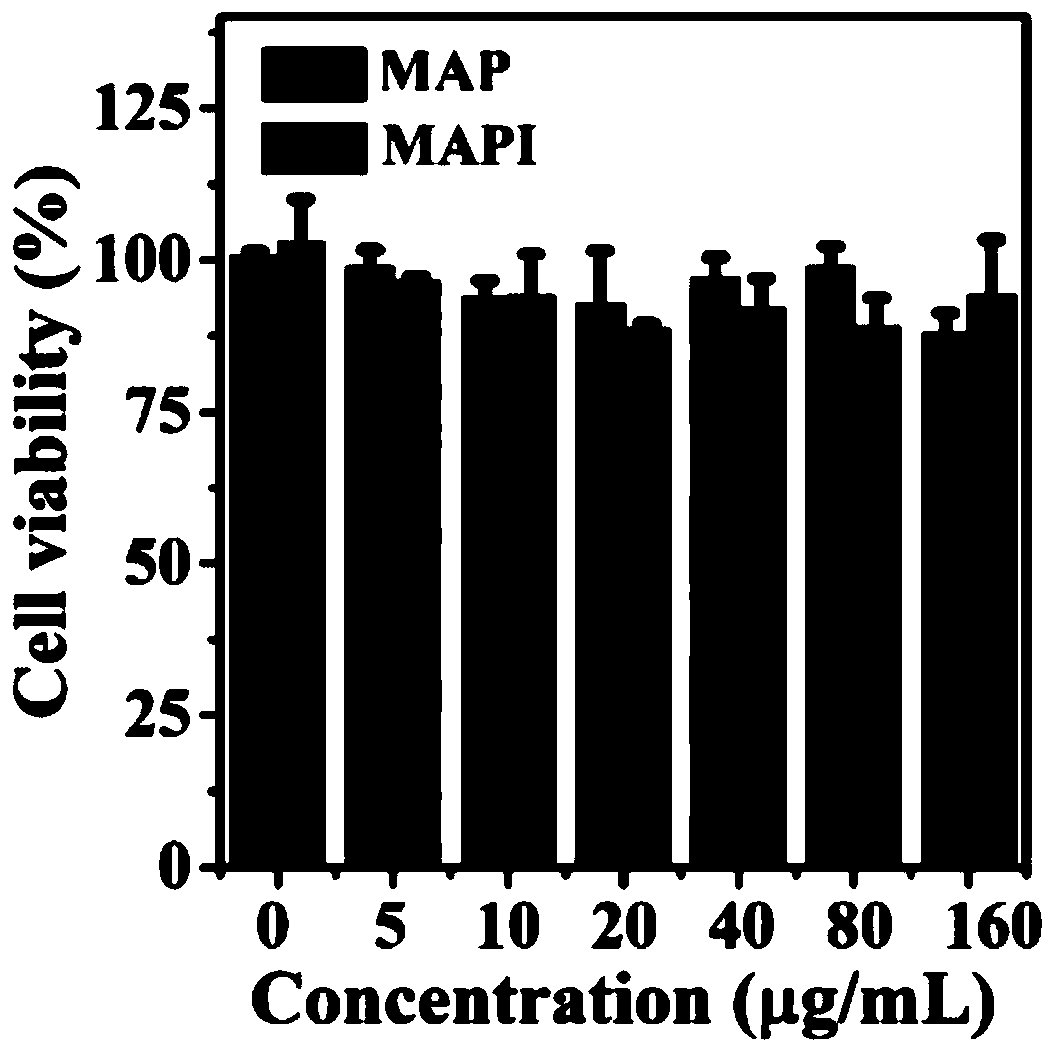

[0041] Biocompatibility of MAPI Nanosheets

[0042] HeLa cells were cultured in DMEM medium containing FBS (10%), penicillin (80 U / mL) and streptomycin (0.08 mg / mL). Add the collected logarithmic phase cells into a 96-well plate (100 μL per well, adjust the cell density to 10 3 -10 4 / hole), placed in a 5% CO 2 Incubate in a 37°C incubator. After the cells adhered to the wall, the culture medium was removed, and 100 μL of MAP (MnO 2 : 0, 5, 10, 20, 40, 80, 160 μg / mL; amylase: 0, 18, 36, 72,144, 288, 576 μg / mL) and MAPI (MnO 2 : 0, 5, 10, 20, 40, 80, 160 μg / mL; amylase: 0,18, 36, 72, 144, 288, 576 μg / mL; ICG: 0, 1.6, 3.2, 6.4, 12.8, 25.6 , 51.2 μg / mL) of DMEM medium (5 replicate wells for each concentration), and then placed in a 5% CO 2 Incubate for 24 h in a 37°C incubator in the dark. Afterwards, 20 μL of MTT solution (5 mg / mL, 0.5% MTT) was added to each well, and the incubation was continued for 4 h in an incubator protected from light. The incubation was terminate...

Embodiment 3

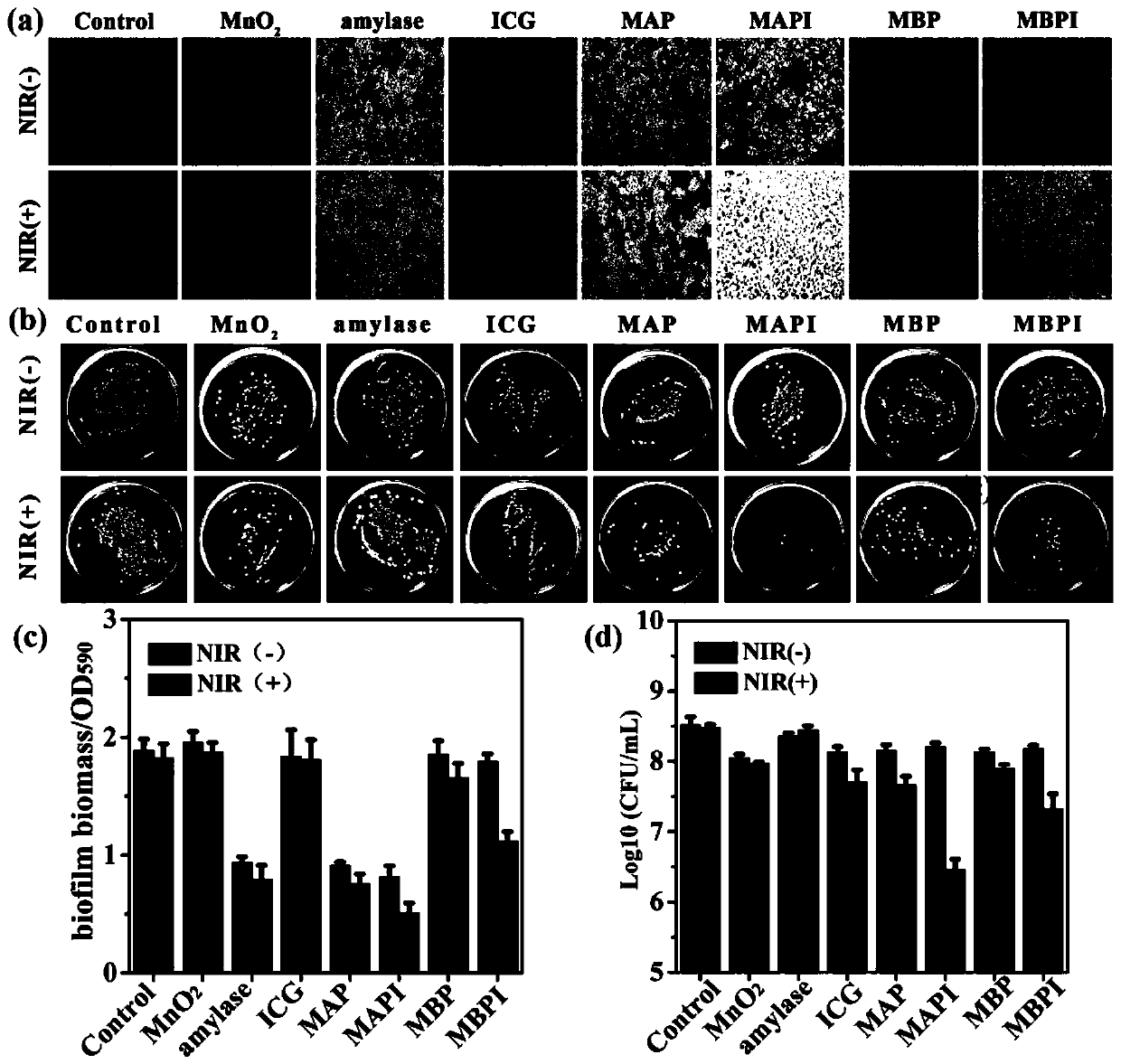

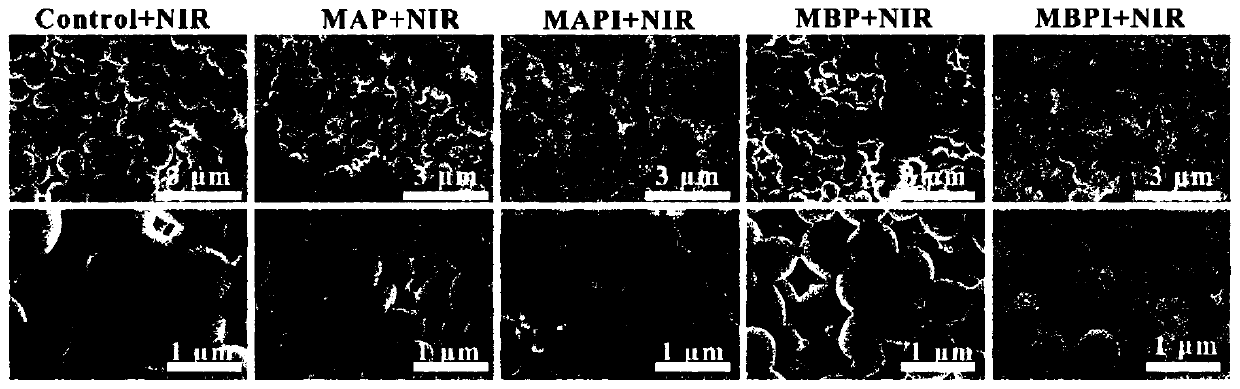

[0045] The effect of MAPI nanosheets on removing bacterial biofilm

[0046] Stretch out a single colony of methicillin-resistant Staphylococcus aureus (MRSA, ATCC43300) in 5 mL of liquid LB medium, incubate and grow in a constant temperature shaker for 10-12 h (rotational speed: 220 rpm, temperature: 37°C), and obtain the Count the MRSA suspension in growth phase. Wash the bacterial solution three times with normal saline (centrifugation condition: 10000 rpm, 3 min), and quantify it with a microplate reader (OD 600 = 0.1, the bacterial solution concentration is 1×10 7 CFU / mL). Dilute the washed bacterial solution to 1×10 with LB medium containing 1% glucose 8 CFU / mL was added to a 96-well plate (200 μL per well) and a 6-well plate containing silicon chips (3 mL per well), and incubated in a 37°C incubator for 2 days to obtain MRSA biofilms.

[0047] (A) Crystal violet staining method

[0048] refer to figure 2 a and 2c, remove the supernatant from the biofilm grown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com