Laser melting deposition ceramic particle enhanced metal-base composite coating based on tubular powder core wire and machining method

A laser melting deposition, metal matrix composite technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of insufficient metallurgical reaction, pore cracks, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

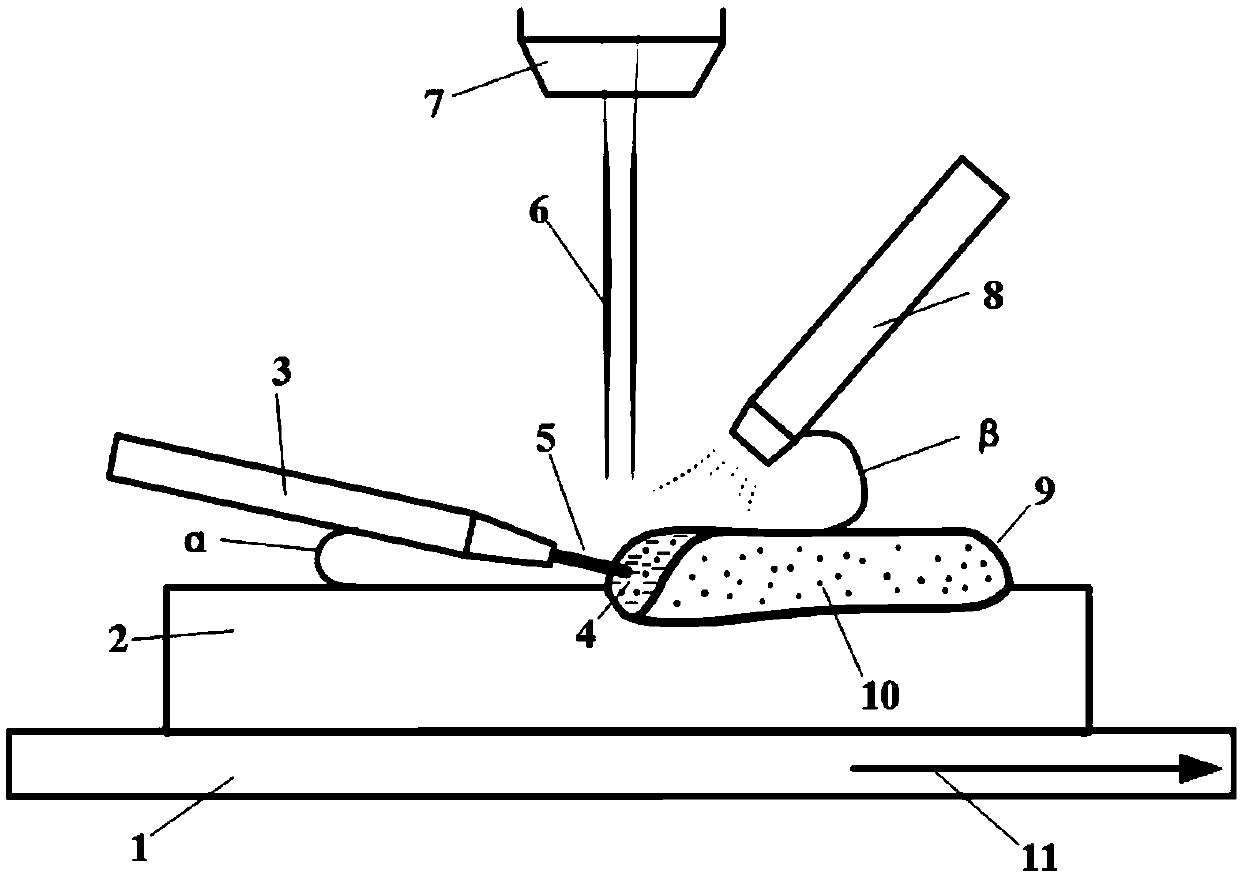

[0038] The technical scheme of the present invention concerning laser melting deposition of particle-reinforced metal-based composite coatings based on tubular powder core wires will be further described below in conjunction with specific examples.

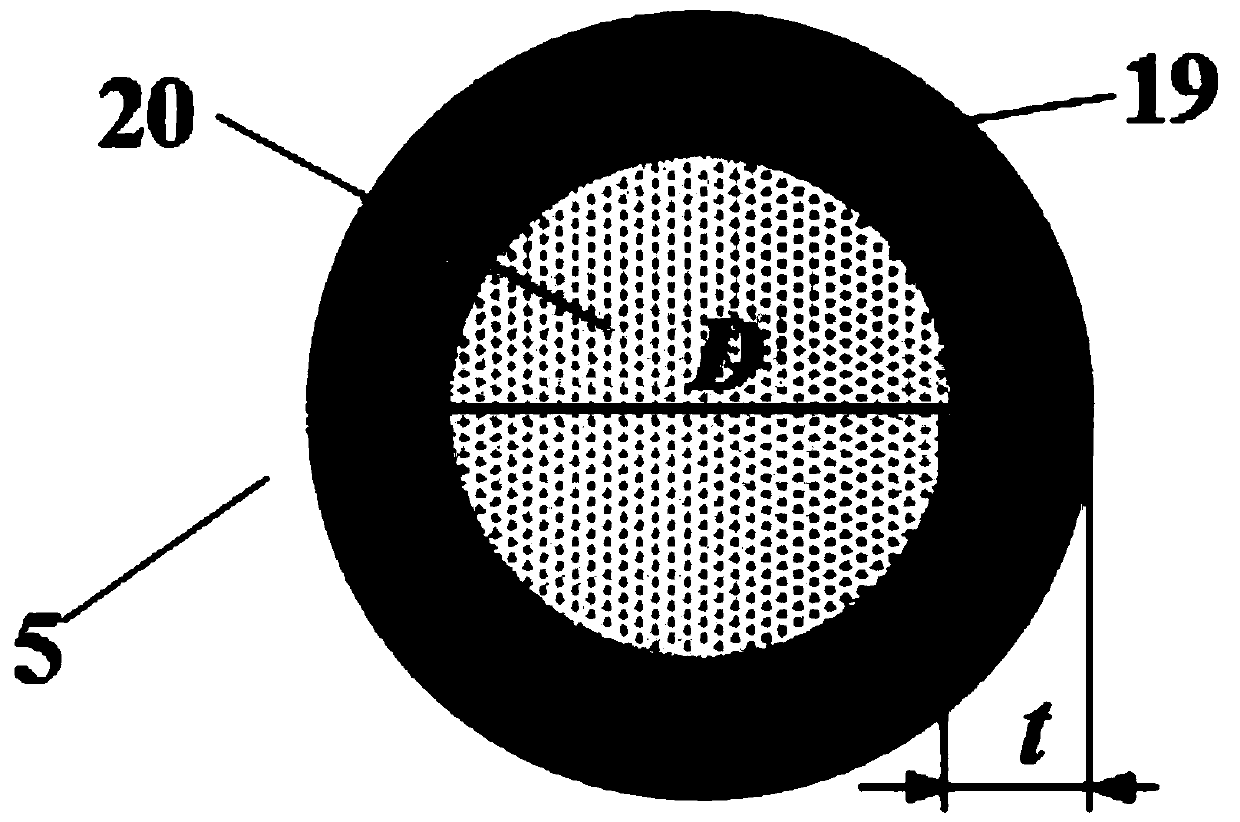

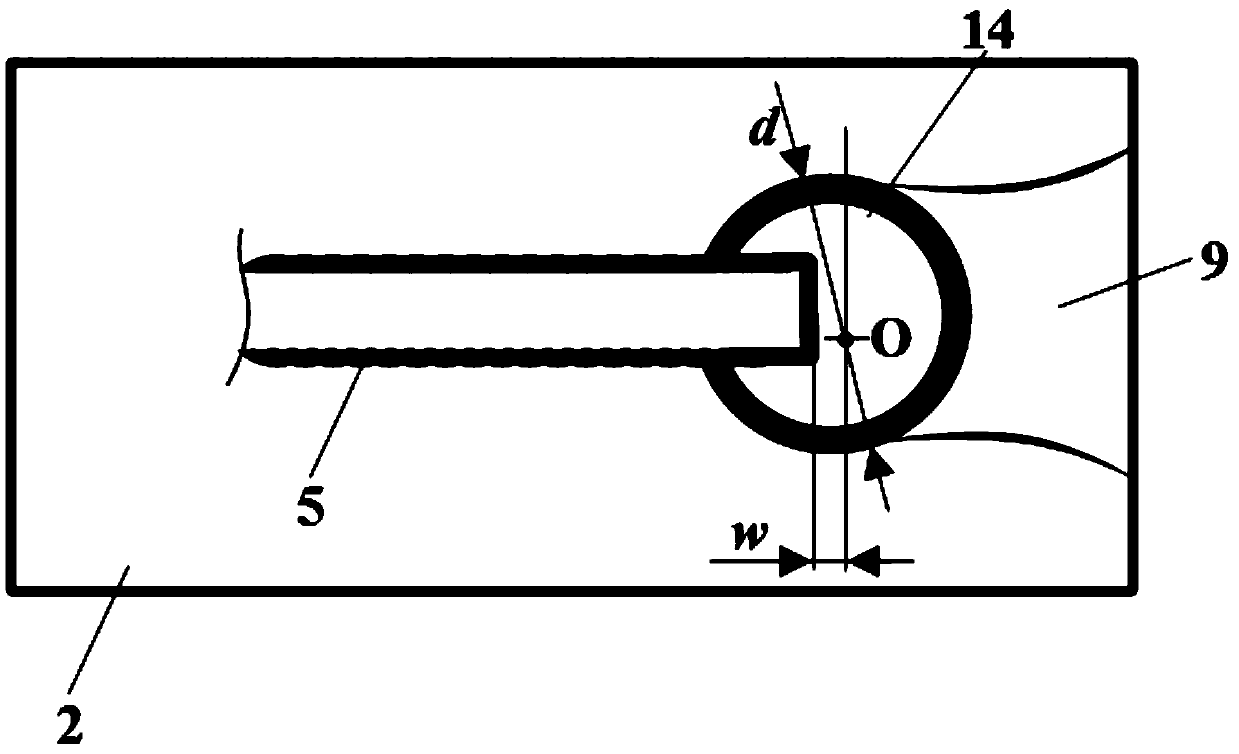

[0039] The example of the present invention adopts Fe-WC type tubular powder core wire material, which means that the outer layer metal of the wire material is Fe-based, and the filling ceramic powder adopts WC. The crystal structure of WC is hexagonal, which has the characteristics of high melting point, high hardness, high elastic modulus and high compressive strength, and it is a carbide with high hardness at high temperature, which has good oxidation resistance and corrosion resistance. . Moreover, WC ceramic particles and iron have very good wettability. In the coating, the matrix can cover WC particles to support and protect them. Its cross-section is as follows: figure 2 As shown, the wire diameter is 1.6mm, and the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com