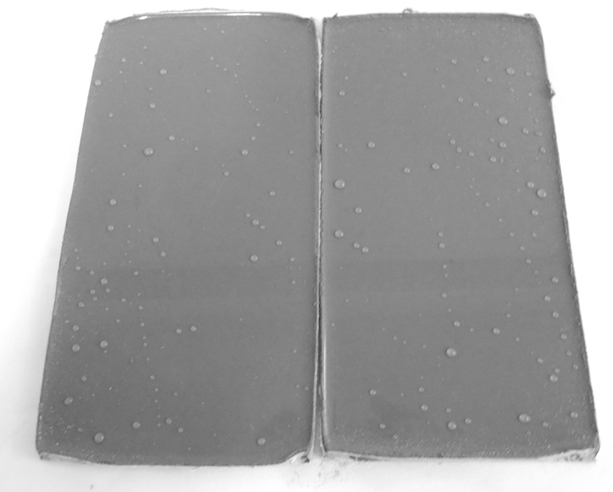

Anti-corrosion and anti-fouling integrated coating for coating repair and preparation method thereof

An anti-fouling and coating technology, which is applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of long maintenance cycle, high cost, and complicated maintenance procedures, so as to reduce maintenance costs and reduce the number of construction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

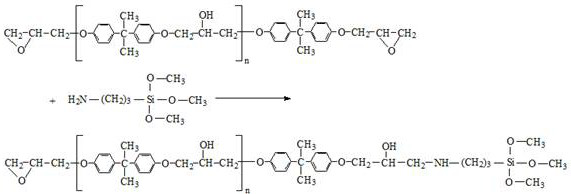

[0034] The preparation method of the anti-corrosion and anti-fouling integrated coating for coating repair of the present invention comprises the following steps:

[0035] (1) Preparation of anti-corrosion components: first mix epoxy resin, modified epoxy resin, bifunctional reactive diluent, fumed silica and anti-rust pigments and fillers, disperse for 20-40 minutes, add solvent to adjust viscosity, and continue to disperse After 3-5 hours, the material can be discharged after being fully dispersed and evenly distributed. After the material is discharged, it will be packaged separately with the amine curing agent.

[0036] (2) Preparation of antifouling components: first add hydroxy silicone resin, phenylmethyl silicone oil, fumed silica and antifouling additives to mix, disperse for 20-40 minutes, add solvent to adjust viscosity, continue to disperse for 3-5 hours , It can be discharged after being fully dispersed and uniform. When using, add silane crosslinking agent in pro...

Embodiment 1

[0041] By weight percentage, take 30% of epoxy resin, 1% of modified epoxy resin, 30% of bifunctional reactive diluent, 0.5% of fumed silica, 10% of aluminum tripolyphosphate, 4.5% of zinc phosphate, sericite powder 4%, precipitated barium sulfate 5%, amidoamine curing agent 15%. Mix the other raw materials except the amidoamine curing agent, disperse at high speed for 25 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3.5 hours, and discharge after fully dispersing evenly;

[0042] By weight percentage, take 75% of hydroxyl silicone resin, 3% of phenylmethyl silicone oil, 3% of fumed silica, 4% of zinc pyrithione, 6% of ECONEA, 3% of Irgarol 1051 and 6% of epoxy silane . Mix the other raw materials except epoxy silane, disperse at high speed for 30 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 4 hours, fully disperse and evenly discharge.

[0043] Before construction, mix the amine curing agent in the anti-...

Embodiment 2

[0045] By weight percentage, take 20% of epoxy resin, 5% of modified epoxy resin, 35% of bifunctional reactive diluent, 1% of fumed silica, 12% of aluminum tripolyphosphate, 5% of zinc phosphate, and sericite powder 3%, precipitated barium sulfate 1%, polyether amine curing agent 18%. Mix the other raw materials taken except polyetheramine curing agent, disperse at high speed for 40 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3 hours, and discharge after fully dispersing evenly;

[0046] By weight percentage, take 78% of hydroxyl silicone resin, 2% of phenylmethyl silicone oil, 2% of fumed silica, 3% of zinc pyrithione, 4% of ECONEA, 4% of Irgarol 1051 and 7% of ketoximosilane . Mix the other raw materials except ketoximosilane, disperse at high speed for 40 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3 hours, fully disperse and evenly discharge.

[0047] Before construction, mix the amine curing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com