Method and material for strengthening electric tunnel with fiber grid reinforced polymer mortar

A technology of fiber mesh and power tunnels, which is applied in tunnels, tunnel linings, earthwork drilling, etc., and can solve problems such as easy rust and corrosion of steel bars, reinforcement failure, and easy falling off of fiber cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

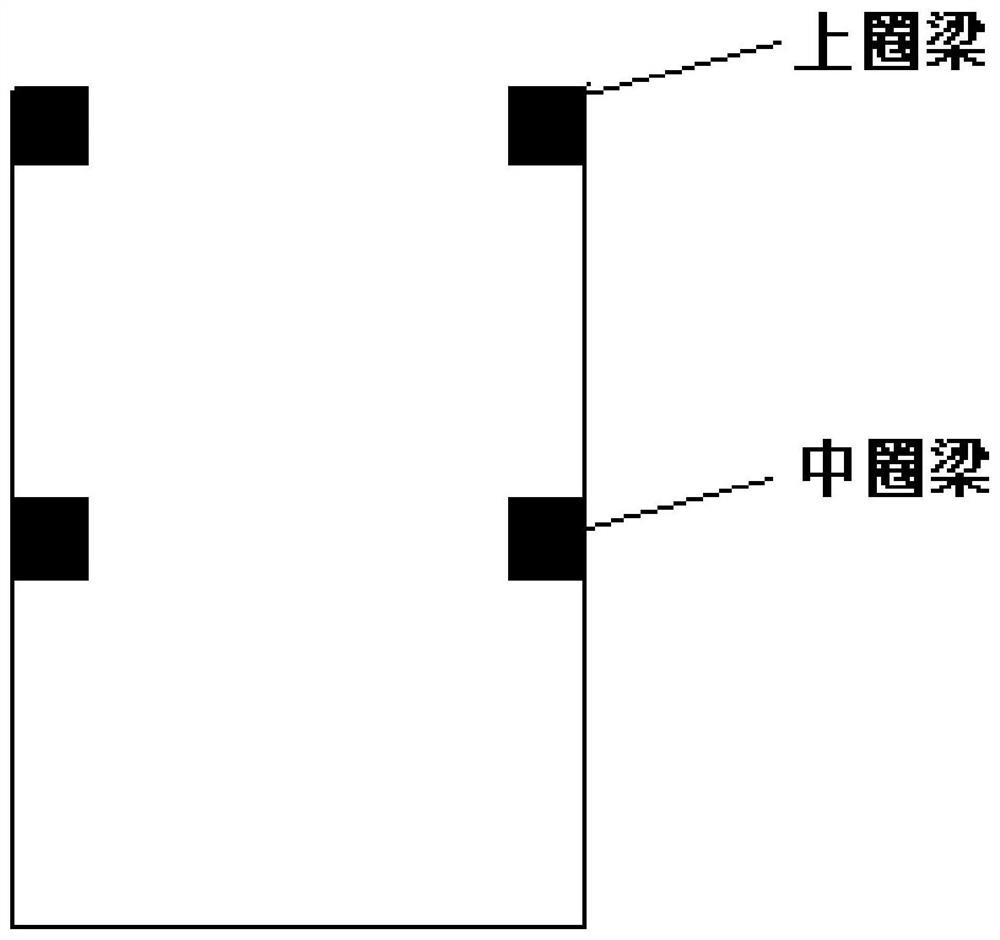

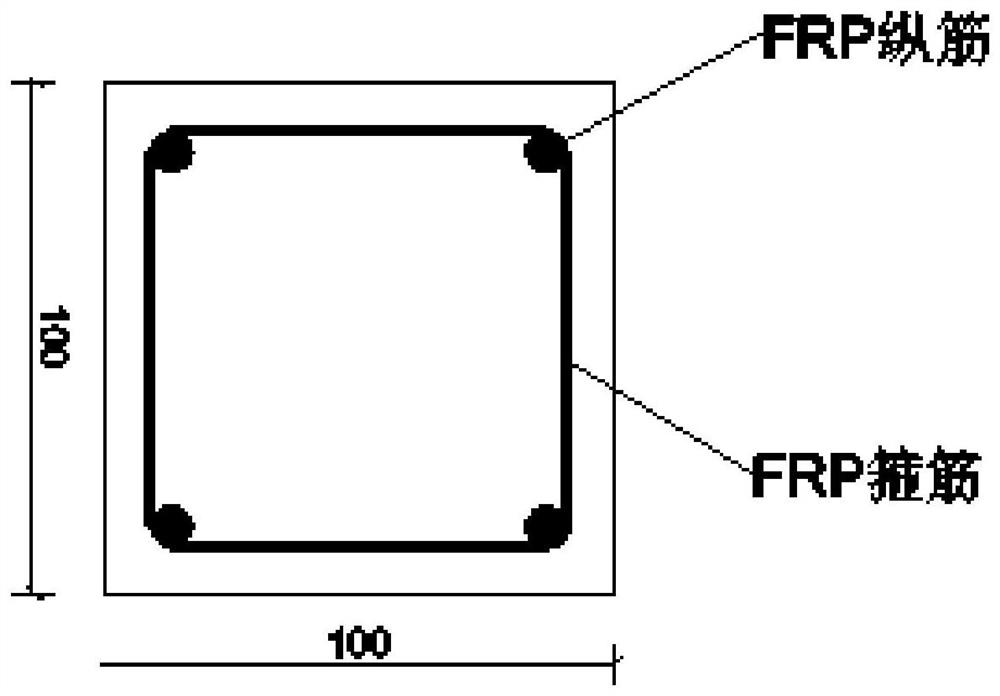

[0041]The wall of the original inspection shaft was a masonry structure, with bricks and cracks and local cracks of 2-4cm. The basalt fiber mesh is reinforced with polymer mortar. The polymer mortar is composed of Portland cement, polyvinyl acetate emulsion, polyvinyl alcohol fiber, alkali-resistant glass fiber, sand, water, water reducing agent, starch ether, cellulose ether, etc. P·Ⅱ52.5 cement accounts for 22% of the total mass of mortar; polyacetic acid emulsion accounts for 11% of the total mass of mortar; polyvinyl alcohol fiber length 12-15mm, diameter 40-55μm, strength 1700MPa, mass content 0.4%; at the same time The length of alkali-resistant glass fiber is 10-18mm, the diameter is 40-80μm, the tensile strength is 1800MPa, the mass content is 0.5%, the water-cement ratio is 0.44, and the polycarboxylate superplasticizer is 0.15% of the cement mass. Starch ether, cellulose ether, etc. are 0.01% of the cement mass. Sand accounts for 31% of the mortar mass, and the san...

Embodiment 2

[0043] The original tunnel wall was a reinforced concrete structure, and the steel bars were corroded, the protective layer was cracked, the concrete cracks were 2-3cm, and the concrete protective layer fell off in some places. Reinforced with alkali-resistant glass fiber mesh reinforced water-based epoxy mortar. Epoxy mortar consists of: high belite sulfoaluminate cement, water-based epoxy, polyvinyl alcohol fiber, alkali-resistant glass fiber, sand, water, water reducing agent, starch ether, cellulose ether, etc. High Belite sulfoaluminate cement accounts for 17% of the total mass of mortar; water-based epoxy accounts for 6% of the total mass of mortar; polyvinyl alcohol fiber length 12-15mm, diameter 40-55μm, strength 1700MPa, mass content 0.4% Alkali-resistant glass fiber length 10-18mm, diameter 40-80μm, tensile strength 1800MPa, mass content 0.5%; water-cement ratio 0.42; polycarboxylate superplasticizer 0.15% of cement mass. Starch ether, cellulose ether, etc. are all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com