Corynebacterium glutamicum for high yield of L-glutamine as well as construction method and application thereof

A technology of Corynebacterium glutamicum and glutamine, applied in the field of bioengineering, can solve the problems of low L-Gln conversion rate, poor fermentation performance, can not meet large-scale industrial production, etc., and achieves improved yield and conversion rate, high Conversion rate, effect of broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

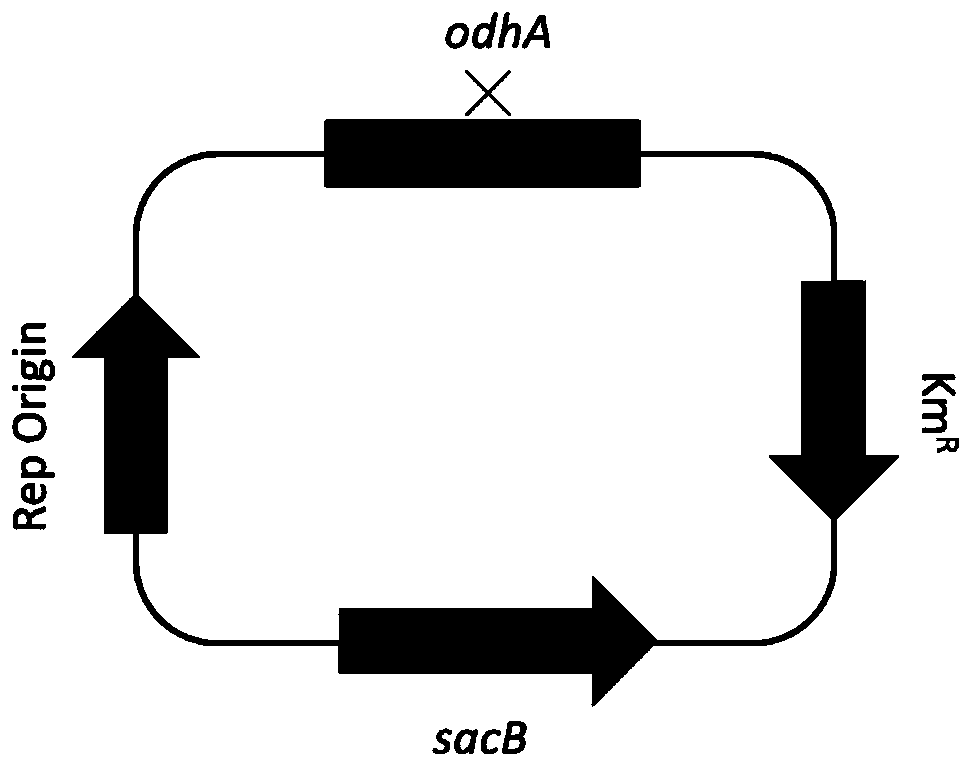

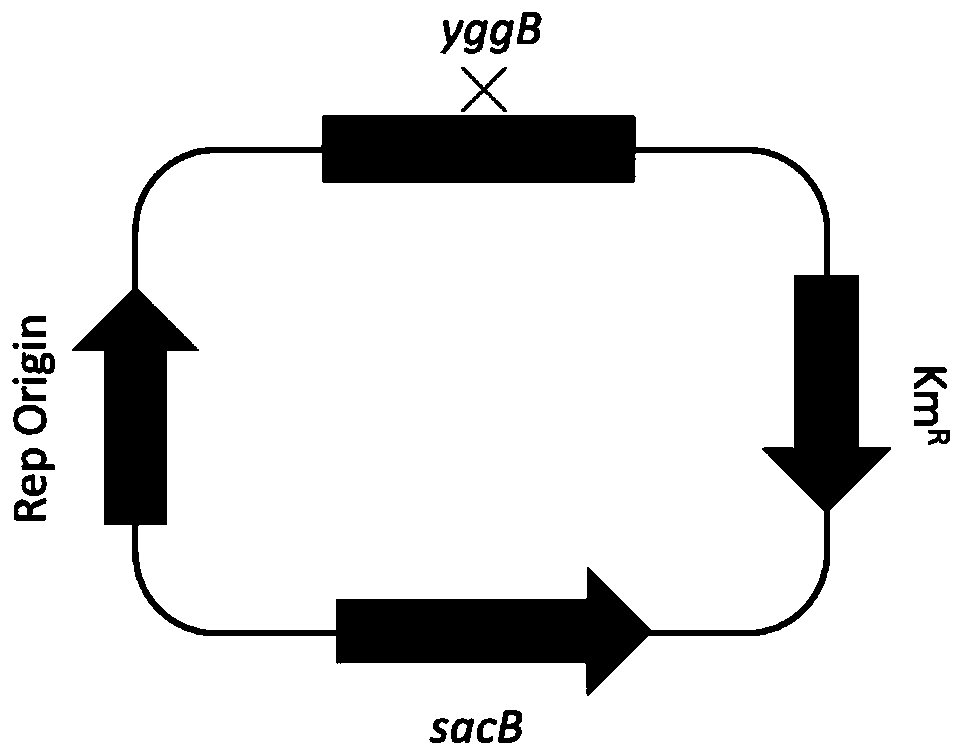

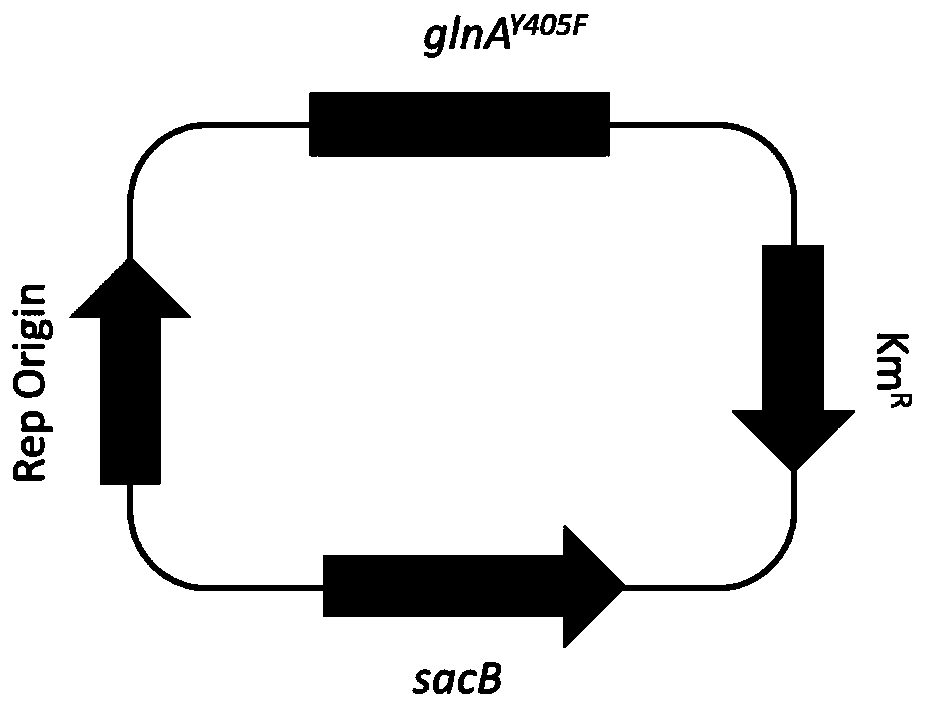

[0049] Example 1: Recombinant plasmids pK18mobsacB-ΔodhA, pK18mobsacB-ΔyggB, pK18mobsacB-glnA Y405F build

[0050] Obtain the nucleotide sequence of Corynebacterium glutamicum ATCC13032 odhA gene in NCBI GenBank database, design (knock out this gene ORF sequence 1-500 500bp nucleotide sequence) to introduce base deletion to make odhA gene For inactivation, four primers were synthesized based on the base sequence and the selected deletion position (as shown in Table 1). Using Phusion ultra-fidelity polymerase (New England BioLabs), using A1 / A2, A3 / A4 as primers, and using the genomic DNA of Corynebacterium glutamicum ATCC 13032 as a template to prepare the upstream and downstream homology arms of the odhA base deletion site Fragment, wherein the odhA upstream homology arm sequence is shown in SEQ ID NO.16, and the odhA downstream homology arm sequence is shown in SEQ ID NO.17). The PCR program was denaturation at 98°C for 10s, renaturation at 50°C for 20s, extension at 72°C f...

Embodiment 2

[0055] Embodiment 2: construct the bacterial strain that odhA gene disrupts from Corynebacterium glutamicum species ATCC 13032 bacterial strain

[0056] Preparation of Competent Corynebacterium glutamicum: transfer Corynebacterium glutamicum species ATCC13032 from the -80°C refrigerator to a BHI plate and culture at 30°C; pick a single colony and transfer it to a 5ml BHI liquid medium test tube medium, 200rpm, 30°C for 12h; inoculate 1% inoculum into 100ml BHIS liquid medium (3.7% brain heart extract powder, 9.1% sorbitol), 200rpm, 30°C until the OD600 reaches 1.5; 4°C, Centrifuge at 6000rpm for 20min, collect the bacteria, discard the supernatant; suspend in TGBuffer (1mM Tris, 10% glycerol (v / v), pH7.5), centrifuge at 4°C for 20min at 6000rpm, discard the supernatant, and repeat ; suspend with 10% glycerol, centrifuge at 4°C, 6000rpm for 20min, discard the supernatant, and repeat again; add 1ml of 10% glycerol to suspend the bacteria, and pack. Store the competent cells in ...

Embodiment 3

[0059] Embodiment 3: construct the bacterial strain that yggB gene destroys from ATCC 13032 bacterial strain

[0060] Preparation of Competent Corynebacterium glutamicum: transfer Corynebacterium glutamicum species ATCC13032 from the -80°C refrigerator to a BHI plate, and culture at 30°C; pick a single colony and transfer to 5ml BHI liquid medium ( 3.7% brain heart extract powder) test tube, 200rpm, 30 ℃ culture 12h; Inoculate in 100ml BHIS liquid culture medium (3.7% brain heart extract powder, 9.1% sorbitol) by 1% inoculum amount, 200rpm, 30 ℃ cultivate to OD 600 reached 1.5; centrifuge at 6000rpm at 4°C for 20min, collect the bacteria, discard the supernatant; suspend with TG Buffer (1mM Tris, 10% glycerol (v / v), pH7.5) and centrifuge at 4°C at 6000rpm for 20min , discard the supernatant, and repeat; suspend with 10% glycerol and centrifuge at 4°C, 6000rpm for 20min, discard the supernatant, and repeat; add 1ml of 10% glycerol to suspend the cells and aliquot. Store the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com