A method for preparing SSZ-39 molecular sieve using fluorine-modified Y-type molecular sieve as raw material

A technology of SSZ-39 and molecular sieves, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of inapplicable control indicators, complicated preparation process, and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 2247.6g of deionized water, 359.7g of 30wt% sodium hydroxide aqueous solution and 1385.2g of 31.5wt% N,N-dimethyl-3,5-dimethylpiperidinium hydroxide aqueous solution, After stirring and mixing for 0.5 hours at 35°C, add 1004.7g of fluorine-modified Y-type molecular sieve F-USY-3 (SiO 2 / Al 2 o 3 Molar ratio=22.60), continue stirring and mixing at 25~35° C. for 0.5 hour.

[0045] SiO in the final sol 2 :Al 2 o 3 :Na 2 O:ROH:H 2 O molar ratio 22.60:1.00:2.10:4.20:300.00

[0046] The above sol was transferred to a steel autoclave lined with polytetrafluoroethylene, and crystallized at a stirring speed of 50 rpm and a temperature of 135° C. for 7 days.

[0047] After the crystallization reaction is completed, the obtained crystallized product is recovered by filtration, washed with deionized water until the pH is 7-8, and finally dried at 90-120°C. According to powder X-ray powder diffraction (XRD) analysis, the obtained crystallized sample is AEI type zeolit...

Embodiment 2

[0050] Weigh 3579.5g of deionized water, 377.3g of 30wt% sodium hydroxide aqueous solution and 697.8g of 30.2wt% N,N-diethyl-2,6-dimethylpiperidinium hydroxide aqueous solution, After stirring and mixing for 0.5 hours at 35°C, add 346.0g of fluorine-modified Y-type molecular sieve F-USY-4 (SiO 2 / Al 2 o 3 Molar ratio=30.51), continue stirring and mixing at 25~35° C. for 6 hours.

[0051] SiO in the final sol 2 :Al 2 o 3 :Na 2 O:ROH:H 2 O molar ratio 30.51:1.00:8.20:6.50:1400.00

[0052] The above sol was transferred to a steel autoclave lined with polytetrafluoroethylene, and crystallized at a stirring speed of 300 rpm and a temperature of 135° C. for 7 days.

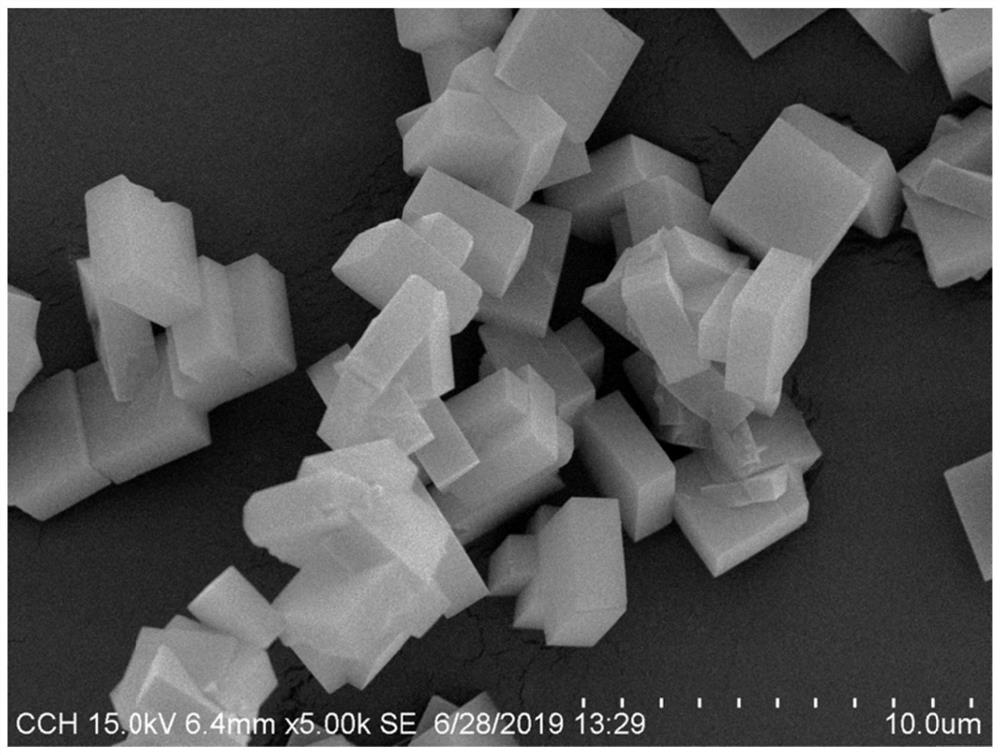

[0053] After the crystallization reaction is completed, the obtained crystallized product is recovered by filtration, washed with deionized water until the pH is 7-8, and finally dried at 90-120°C. According to XRD test, the obtained crystallized sample is AEI type zeolite; figure 1 Scanning electron micrograp...

Embodiment 3

[0056] Weigh 2824.9g of deionized water, 361.3g of 30wt% sodium hydroxide aqueous solution, 287.2g of 31.5wt% N,N-dimethyl-3,5-dimethylpiperidinium hydroxide aqueous solution, 30.2wt% 352.4g of N,N-diethyl-2,6-dimethylpiperidinium hydroxide aqueous solution and 1111.2g of 29.5wt% silica sol were stirred and mixed at 25-35°C for 6 hours, and then 63.0g of Fluorine-modified Y-type molecular sieve F-HY(SiO 2 / Al 2 o 3 Molar ratio=5.19), continue stirring and mixing at 25~35° C. for 6 hours.

[0057] SiO in the final sol 2 :Al 2 o 3 :Na 2 O:ROH:H 2 O molar ratio 46.00:1.00:10.20:8.50:1800.00, where N,N-dimethyl-3,5-dimethylpiperidinium hydroxide and N,N-diethyl-2,6-di The molar ratio of methylpiperidinium hydroxide is 1:1.

[0058] The above sol was transferred to a steel autoclave lined with polytetrafluoroethylene, and crystallized at a stirring speed of 300 rpm and a temperature of 145° C. for 4 days.

[0059]After the crystallization reaction is completed, the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com