Preparation method of cobalt-iron bimetal selenide sodium ion battery negative electrode material

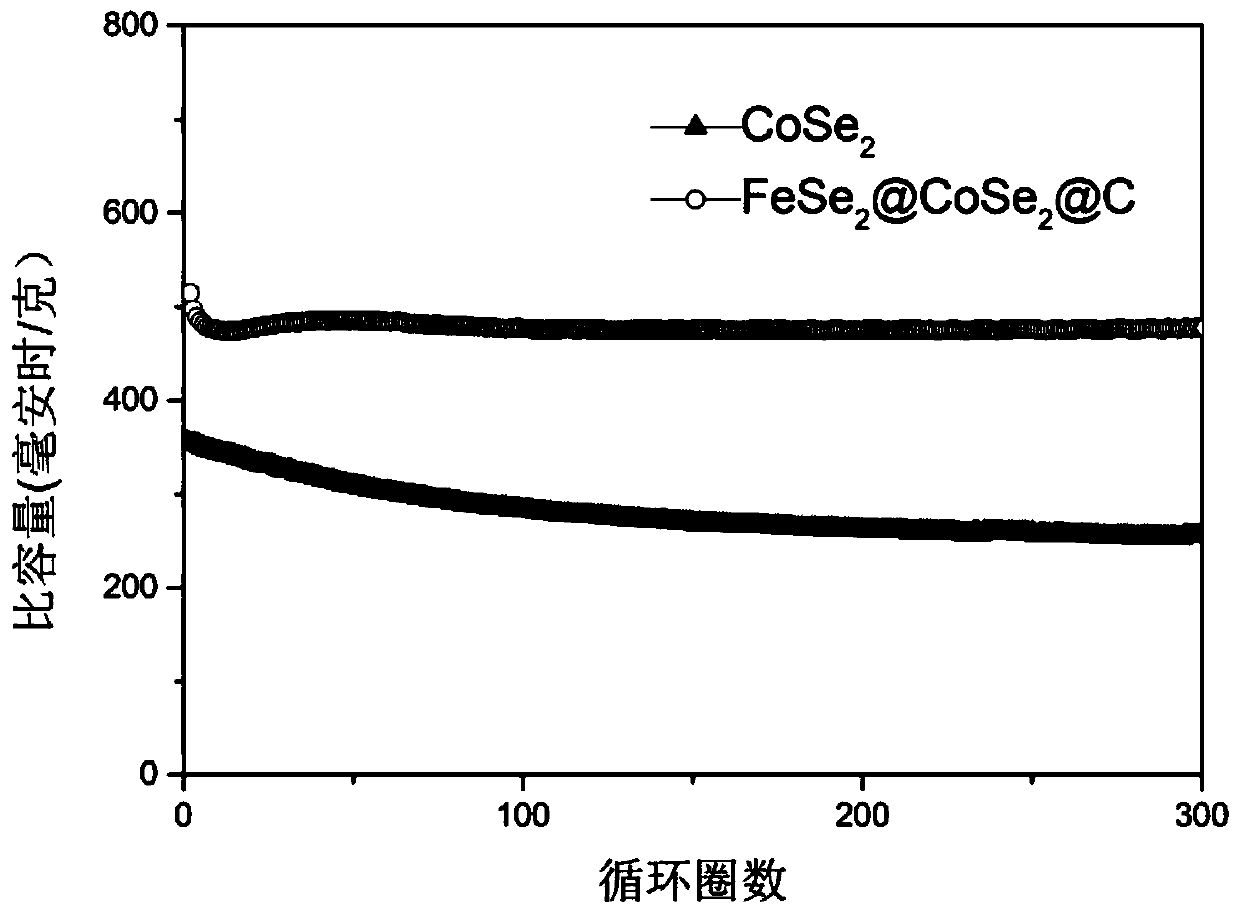

A sodium ion battery and negative electrode material technology, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve problems such as poor cycle life and stable performance, improve cycle performance, increase capacity and service life, and increase specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step: the preparation of ZIF-67 precursor:

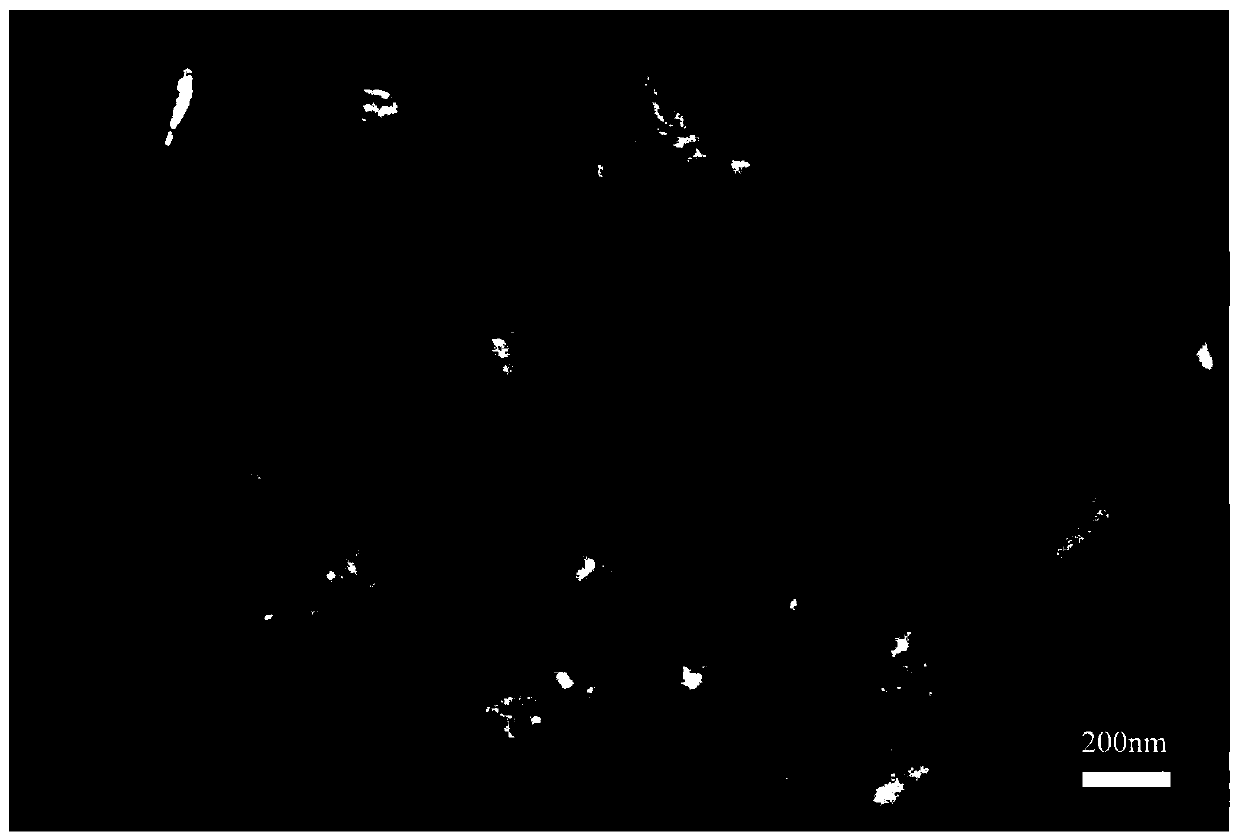

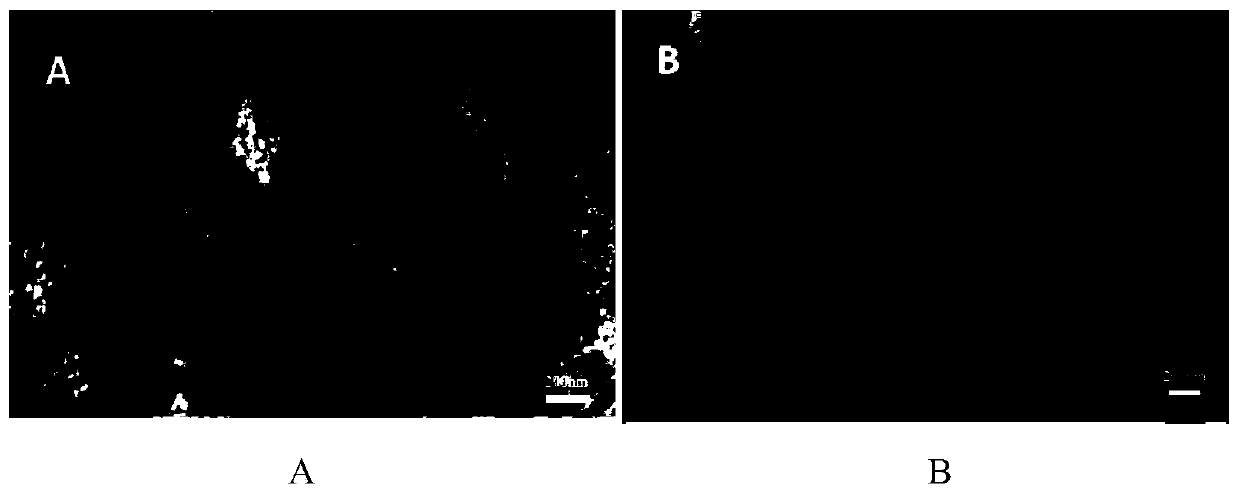

[0028] Dissolve 0.291g of sodium cobaltate nitrate in 20mL of methanol and then stir in a magnetic stirrer at a speed of 400r / min for 5min until completely dissolved, which is marked as solution A. Dissolve 0.658g of 2-methylimidazole in 20 mL of methanol, stir for 5min at a speed of 400r / min in a magnetic stirrer until completely dissolved, and mark it as B solution. Quickly pour solution B into solution A and stir for 5 minutes, let stand at room temperature for 24 hours, collect samples by centrifugation at 8000r / min, wash with methanol three times and dry in an oven at 60°C for later use. attached by figure 1 It can be seen that the shape of the prepared precursor is hexagonal rhombus, uniform in size, and the diameter is about 300-400nm. It can be seen from the picture that the inside is a hexagonal rhombus, and the outside is a layer of small granular iron.

[0029] Step 2: Synthesis of ZIF-67@Fe-LDH struct...

Embodiment 2

[0034] The first step: the preparation of ZIF-67 precursor:

[0035]Dissolve 0.291g of sodium cobaltate nitrate in 20mL of methanol and then stir in a magnetic stirrer at a speed of 400r / min for 5min until completely dissolved and marked as solution A. Dissolve 0.658g of 2-methylimidazole in 20mL of methanol, stir in a magnetic stirrer at a speed of 400r / min for 5min until completely dissolved, and mark it as solution B. Quickly pour solution B into solution A and stir for 5 minutes, let stand at room temperature for 24 hours, collect samples by centrifugation at 8000r / min, wash with methanol three times and dry in an oven at 60°C for later use.

[0036] Step 2: Synthesis of ZIF-67@Fe-LDH structure

[0037] The resulting 0.05 g of ZIF-67 was dissolved in 5 mL of ethanol, marked as solution C, and sonicated for 10 min. The potassium ferricyanide of 0.05g and the PVP that 0.63g molecular weight is 10000 are dissolved in the ethanol solution that 40mL volume fraction is 50%, ma...

Embodiment 3

[0041] The first step: the preparation of ZIF-67 precursor:

[0042] Dissolve 0.291g of sodium cobaltate nitrate in 20mL of methanol and then stir in a magnetic stirrer at a speed of 400r / min for 5min until completely dissolved, which is marked as solution A. Dissolve 0.658g of 2-methylimidazole in 20 mL of methanol, stir for 5min at a speed of 400r / min in a magnetic stirrer until completely dissolved, and mark it as B solution. Quickly pour solution B into solution A and stir for 5 minutes, let stand at room temperature for 24 hours, collect samples by centrifugation at 8000r / min, wash with methanol three times and dry in an oven at 60°C for later use.

[0043] Step 2: Synthesis of ZIF-67@Fe-LDH structure material

[0044] The resulting 0.05 g of ZIF-67 was dissolved in 5 mL of ethanol, marked as solution C, and sonicated for 10 min. The potassium ferricyanide of 0.05g and the PVP that 0.63g molecular weight is 10000 are dissolved in the ethanol solution that 40mL volume fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com