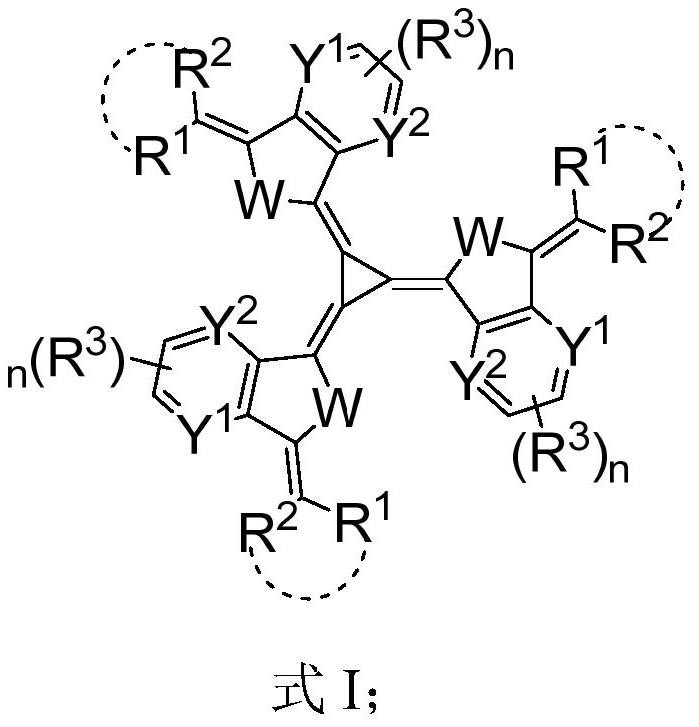

A kind of axene compound and its preparation method and application

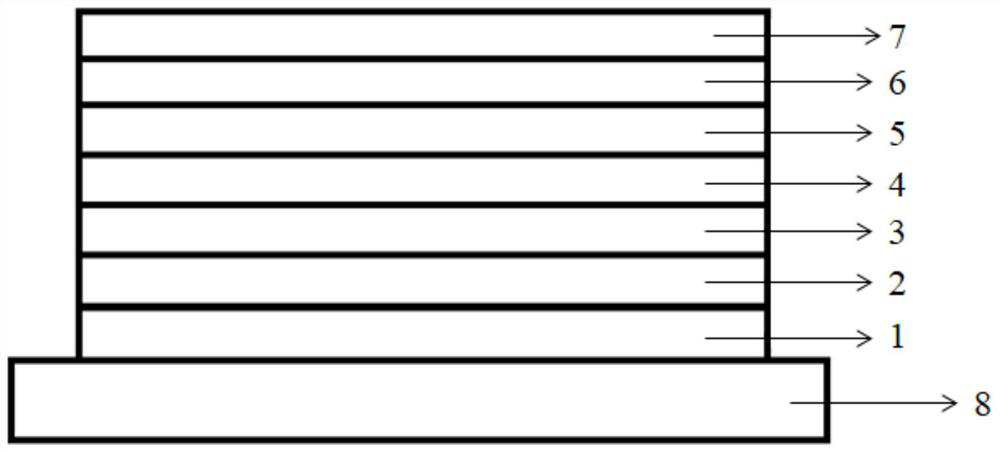

A compound and alkene technology, applied in the field of alkene compounds and their preparation, can solve the problems of short service life, difficult evaporation, small molecular weight, etc., and achieve the effects of improving service life, good thermal stability, and avoiding Joule heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

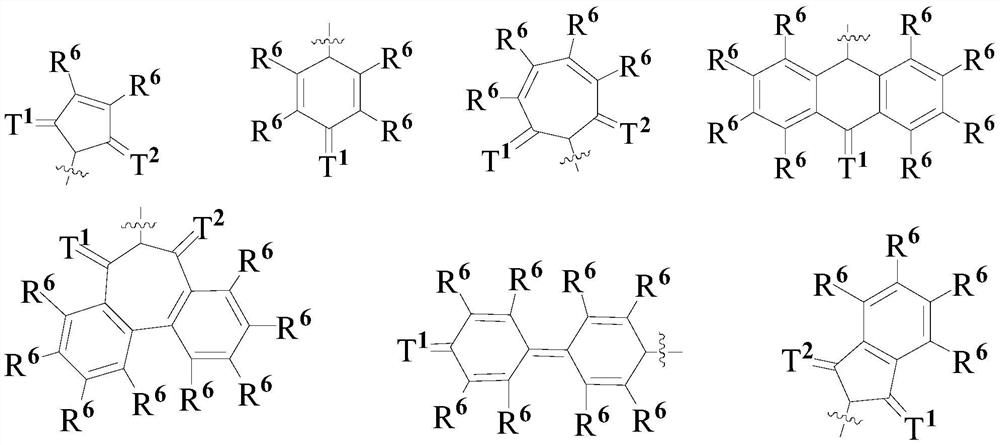

Method used

Image

Examples

preparation example 1

[0075] A kind of alkene compound P1, preparation method is as follows:

[0076]

[0077] (1) Synthesis of P1-B: in a 25mL three-neck flask, under nitrogen protection, add P1-A (1.32g, 0.01mol), malondicyanide (0.66g, 0.01mol), potassium carbonate (2.07g, 0.015mol) ), ethanol (10 mL), stirred at room temperature for 8 h, after the reaction was completed, cooled to room temperature, quenched by adding 5 mL of water, extracted with ethyl acetate (20 mL × 3), dried over anhydrous sodium sulfate, spin-dried, the crude product was separated into layers Analytical purification (dichloromethane / n-hexane volume ratio, 1 / 5) gave P1-B (1.13 g, yield 63%).

[0078] (2) Synthesis of P1-C: in a 25mL three-necked flask, add P1-8 (3.6g, 0.02mol), nitric acid (6mL), react at room temperature for 1 hour, add water to quench, and adjust the pH to 7 with sodium carbonate, Dichloromethane was extracted, the organic layer was dried over anhydrous magnesium sulfate, and the crude product was pur...

preparation example 2

[0083] A kind of alkene compound P2, preparation method is as follows:

[0084]

[0085] P2 was prepared with reference to the preparation method of Preparation Example 1, except that the diaminomaleonitrile in step (3) was replaced by cis-1,2-difluoroethylene-1,2-diamine (0.94 g, 0.01 mol) to give P2 (2.95 g, 40% yield).

[0086] Elemental Analysis: C 30 N 12 F 6 S 3 Theoretical value: C, 48.79; N, 22.76; Measured value: C, 48.84; N, 22.72; HRMS (ESI) m / z (M + ): theoretical value: 737.9435; measured value: 737.9428.

preparation example 3

[0088] A kind of alkene compound P5, preparation method is as follows:

[0089]

[0090] P5 was prepared with reference to the preparation method of Preparation Example 1, except that malononitrile in step (1) was replaced with 1,1,1,3,3,3-hexafluoropropane (1.52g, 0.01mol), and step ( The diaminomaleonitrile in 3) was replaced with cis-1,2-difluoroethylene-1,2-diamine (0.94 g, 0.01 mol) to give P5 (3.78 g, 38% yield).

[0091] Elemental Analysis: C 30 N 6 F 24 S 3 Theoretical value: C, 36.16; N, 8.43; Measured value: C, 36.12; N, 8.40; HRMS (ESI) m / z (M + ): theoretical value: 995.8963; measured value: 995.8957.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com