Barium slag carbon/hydrogen cooperative reduction thermal molten-salt slag-free production process

A production process, technology of hot molten salt, applied in the field of comprehensive utilization of barium slag, can solve the problems of low heat energy utilization rate, unsatisfactory product sales market, etc., and achieve the effect of reasonable investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

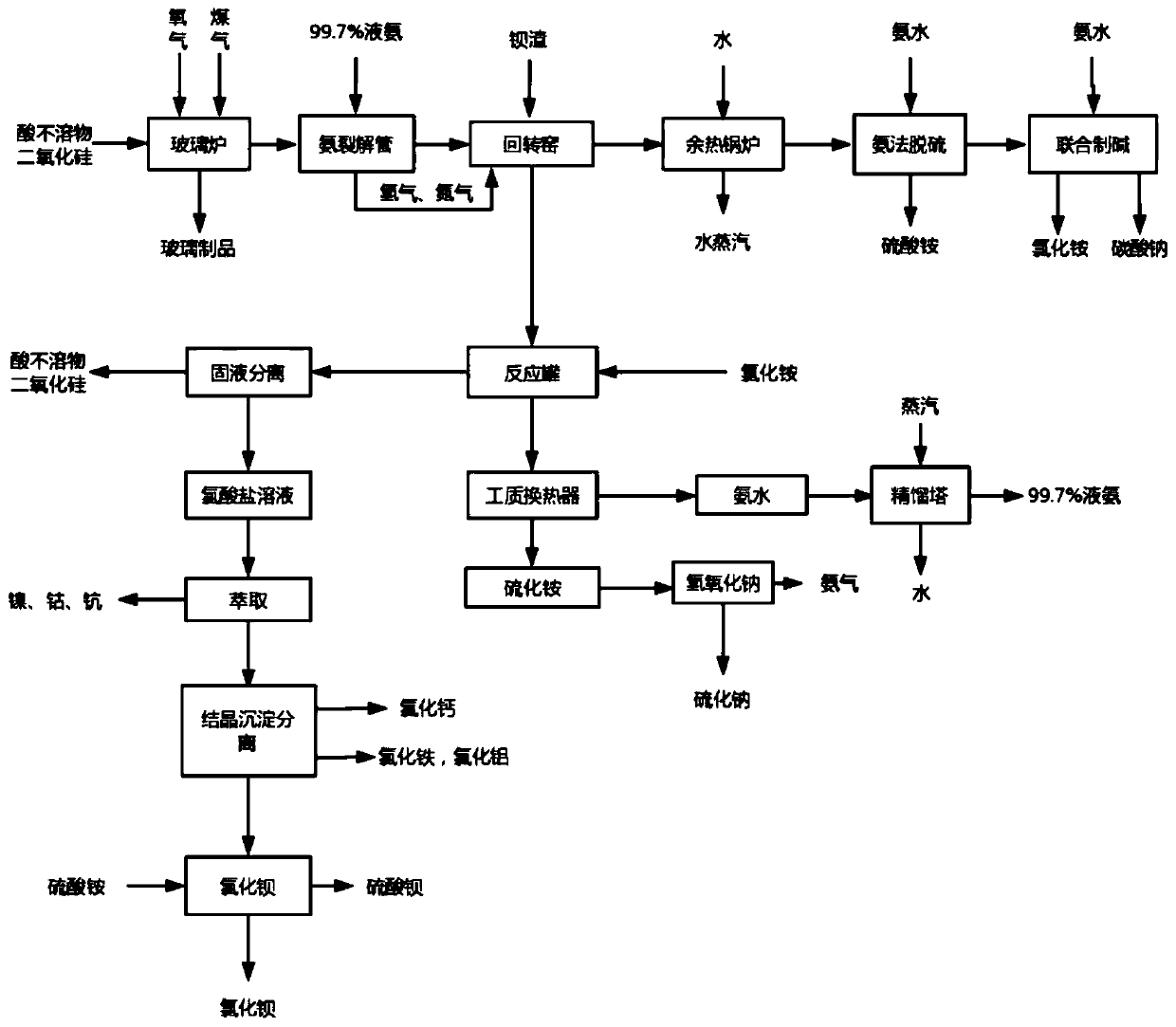

Image

Examples

Embodiment

[0019] The chemical composition of barium slag mainly includes: residual carbon powder 15-18%, silicon dioxide 9-20%, iron sulfide 1-3%, alumina 2-6%, calcium sulfide 2-5%, barium sulfate, sulfide Barium compounds such as barium sulfate, barium carbonate, barium silicate 60-72%. Barium slag carbon-hydrogen synergistic reduction hot molten salt method slag-free production process: barium slag is roasted in a rotary kiln, and the heat energy required for roasting is provided by the exhaust gas of the glass kiln. The glass kiln is used to make barium glass products. Glass kiln Coal gas is used as fuel, pure oxygen or oxygen-enriched combustion is supported, and the temperature of the tail gas of the glass furnace is 1500-1600 degrees Celsius. The high-temperature tail gas of the glass furnace is used to pass through the ammonia cracking tube to produce hydrogen and nitrogen, and directly enter the rotary kiln to roast the barium slag for reduction , while the barium slag has a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com