Trackless transport vehicle for heavy-load logistics system

A logistics system and transport vehicle technology, applied in the field of trackless transport vehicles for heavy-duty logistics systems, can solve the problems of no three-dimensional segmented assembly line, handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

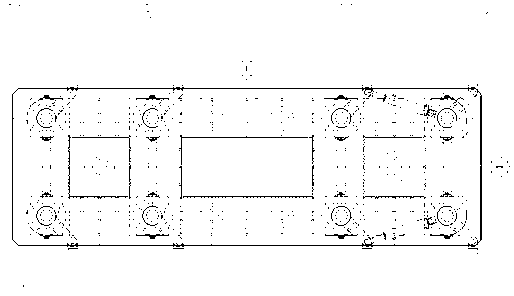

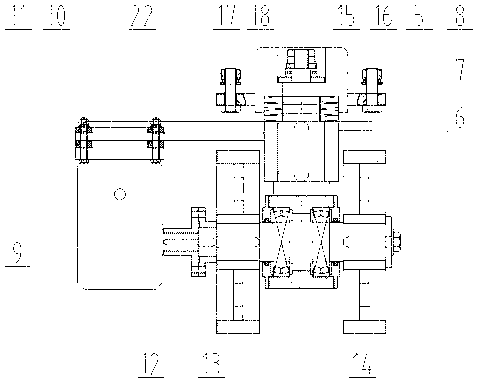

[0013] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 , figure 2 , image 3 Shown: a trackless transport vehicle for a heavy-duty logistics system, including a car body 1 as a base, and a plurality of pairs of wheel sets 2 are arranged at the bottom of the car body 1, and each pair of wheel sets 2 includes two sets of symmetrically arranged wheels In the group assembly, four car body jacking cylinders 3 are arranged in the middle of the car body 1, and every two car body jacking cylinders 3 are regarded as a group, and two groups of car body jacking oil cylinders 3 are arranged symmetrically. The extension direction of the working shaft of the lifting cylinder 3 is downward, and a heavy-duty jacking cylinder 4 is symmetrically arranged on the front and rear of the car body 1, and the extension direction of the working shaft of the heavy-duty jacking cylinder 4 is upward.

[0014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com