Rotary light beam ultra-high-speed laser cladding method

A technology of laser cladding and rotating beam, which is applied in the coating process and coating of metal materials, can solve the problems of large powder consumption, heavy grinding workload, low utilization rate, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

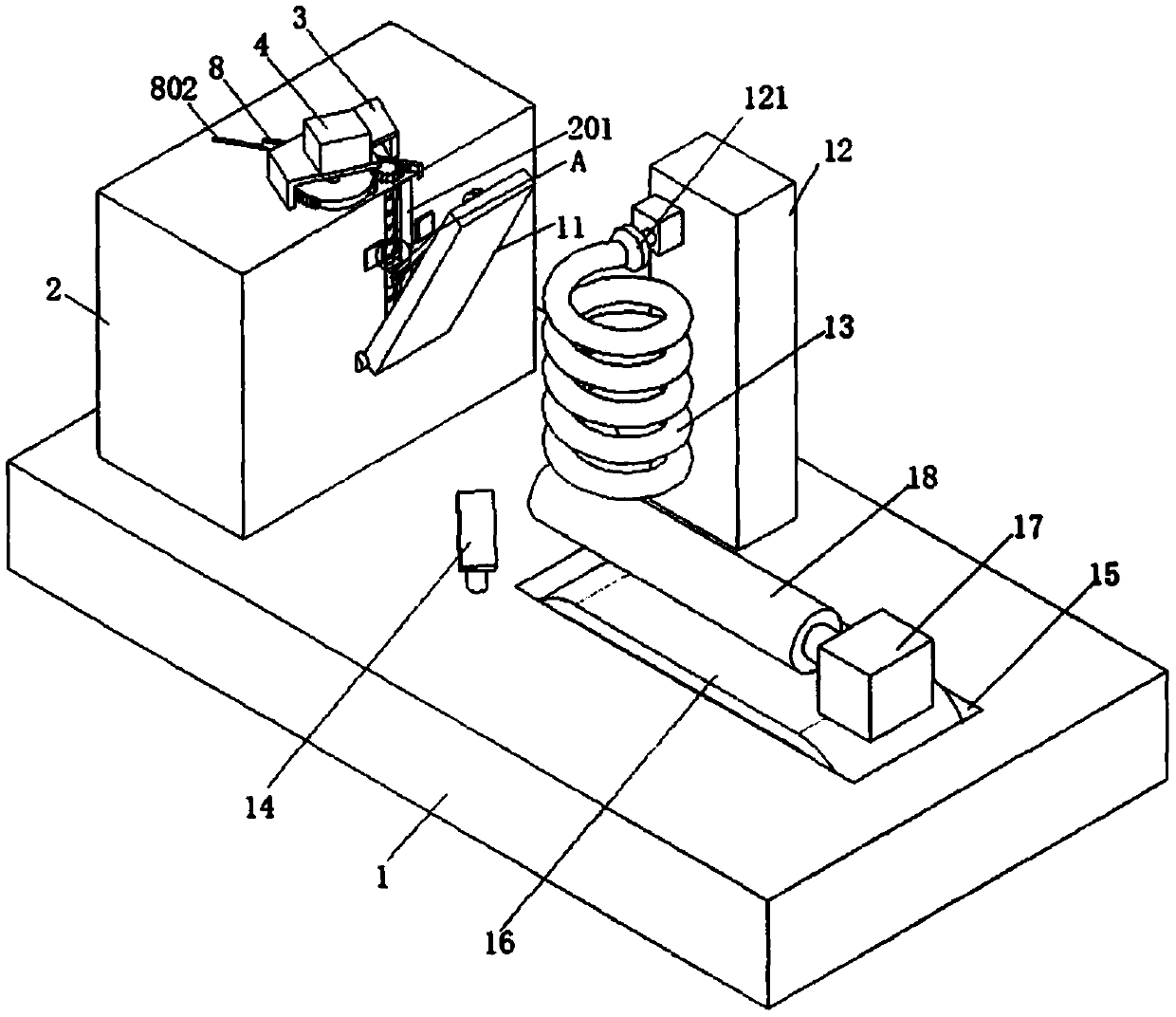

[0035] refer to Figure 1-5 , a rotating beam ultra-high-speed laser cladding method, comprising the following steps:

[0036] S1: Fix the workpiece on the outside of the device, so that the powder ejected from the laser cladding nozzle is placed above the workpiece to be clad through the feeding pipeline;

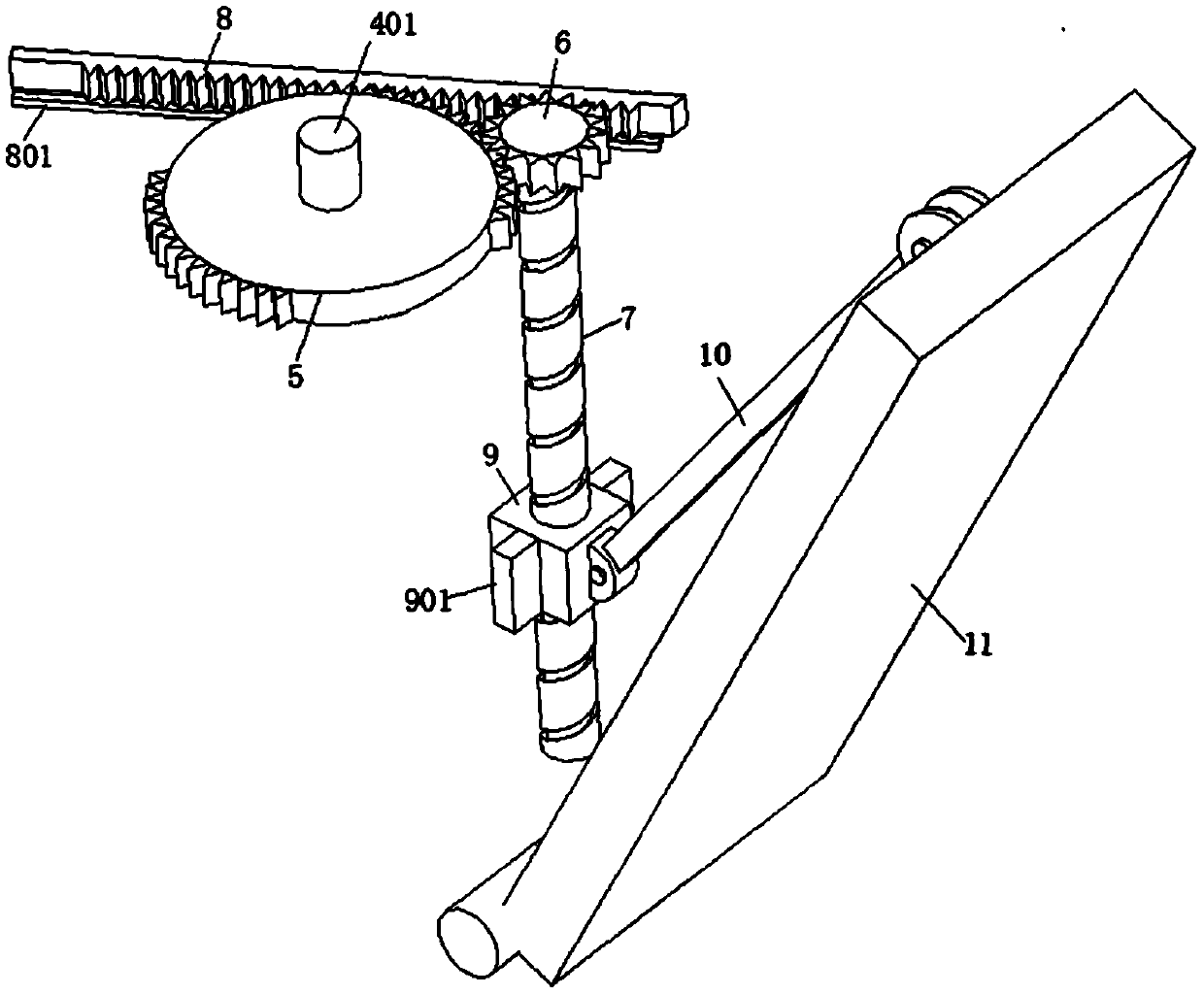

[0037] S2: Control the laser beam to irradiate the rotating prism;

[0038] S3: Adjust the rotational speed of the workpiece so that the rotational speed of the workpiece is set within the range of 25-200m / min;

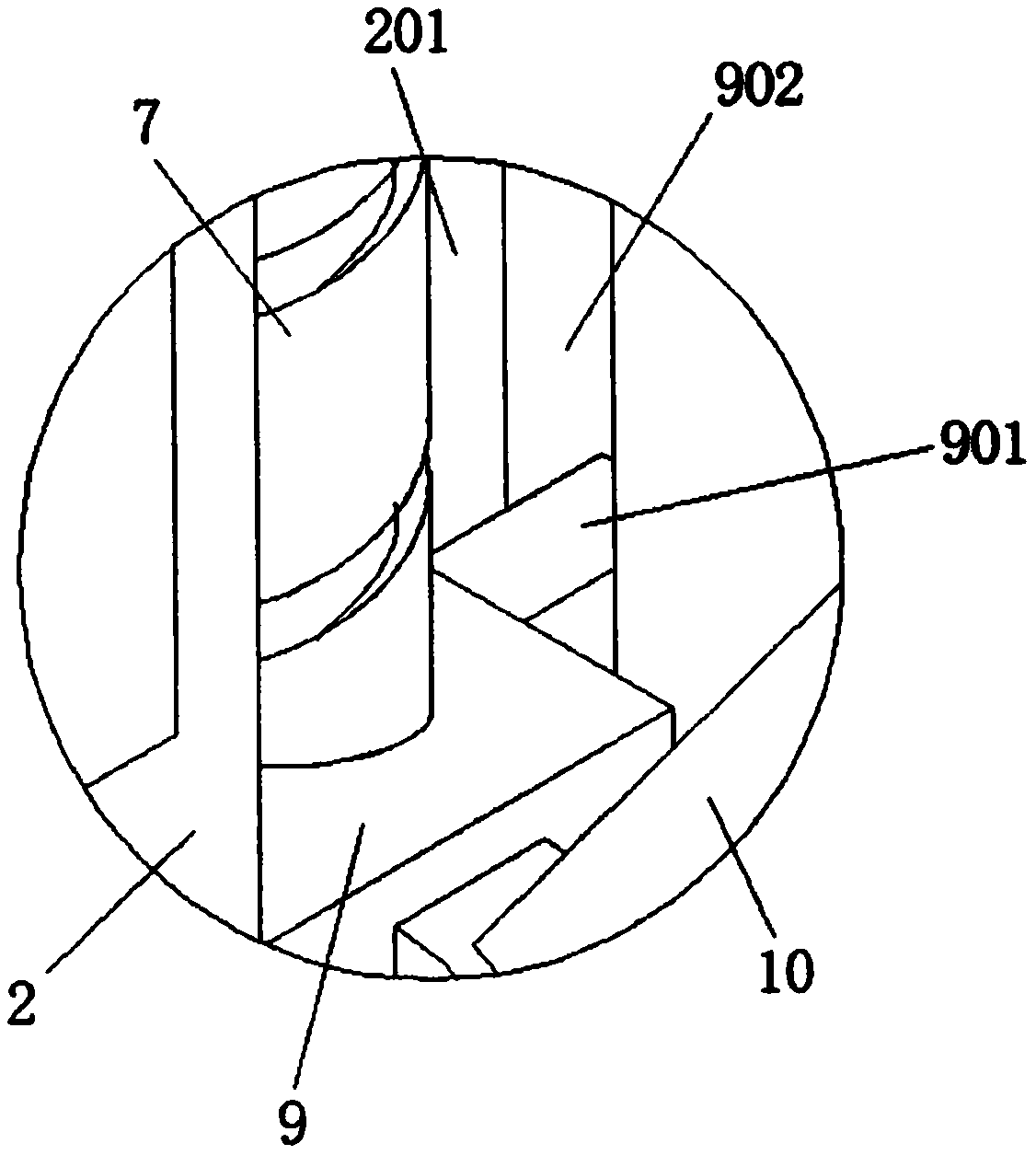

[0039] S4: Start the motor, control the reciprocating movement of the rotating prism, so that the laser beam reflected by the rotating prism irradiates the powder inside the pipeline;

[0040] S5: The powder is heated by uniform laser energy radiation inside the pipe, flows out of the pipe in liquid or semi-solid state and falls into the molten pool, and then cools to form a cladding layer;

[0041] S6: Control the movement of the workpiece to clad the entire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com