Self-repairing normal temperature blackening agent for cold-drawn steel pipes and its preparation method and application

A cold-drawn steel pipe, self-repairing technology, applied in the direction of metal material coating process, can solve the problems of high cost, complicated process and increased operation complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

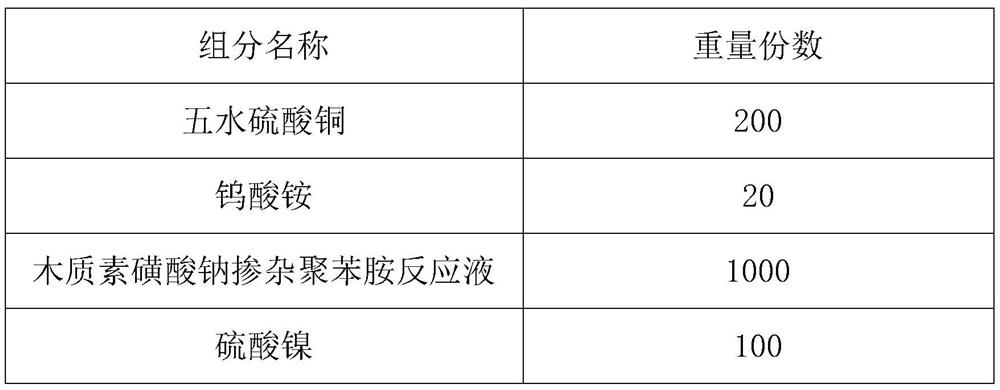

[0025] component name parts by weight Copper Sulfate Pentahydrate 10 Ammonium tungstate 300 Sodium lignosulfonate doped polyaniline reaction solution 700 nickel sulfate 50 ammonium thiosulfate 80 trisodium nitrilotriacetate 40

[0026] The sodium lignosulfonate doped polyaniline reaction solution used above can be synthesized by the following method:

[0027] One, take by weighing 13-24 parts by weight (such as can be 18.6 parts by weight) sodium lignosulfonate, pour it into (0.8-1.2) mol / L of 70-130 parts by weight (such as can be 100 parts by weight) In the sulfuric acid solution (the concentration of sulfuric acid solution is preferably 1mol / L), fully stir and mix evenly, then take 13-24 parts by weight of aniline (for example, it can be 18.6 parts by weight), slowly add in the mixed solution under the action of stirring, fully Stir and mix evenly to prepare liquid D.

[0028] Two, take by weighing the ammonium persulfate ...

Embodiment 2

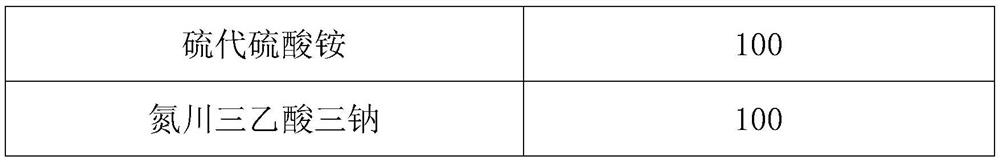

[0032] Embodiment 2 is compared with embodiment 1, only the proportioning of each component changes to some extent, and the proportioning of each component in embodiment 2 is as follows:

[0033]

[0034]

Embodiment 3

[0036] Embodiment 3 compares with embodiment 1 and 2, only the mass percent distribution ratio of each component changes, and the proportioning of each component in embodiment 3 is as follows:

[0037] component name parts by weight Copper Sulfate Pentahydrate 100 Ammonium tungstate 200 Sodium lignosulfonate doped polyaniline reaction solution 50 nickel sulfate 5 ammonium thiosulfate 10 trisodium nitrilotriacetate 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com