Iron-based composite material and its preparation method and application

A technology of iron-based composite materials and pig iron, which is applied in the field of anti-corrosion and wear of liquid metals, can solve problems affecting the application of high-boron alloys, and achieve the effects of improving anti-corrosion efficiency, good bonding, and strengthening anti-corrosion performance of molten aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]

[0035] The preparation method of iron-based composite material of the present invention comprises the steps:

[0036] (1) Add steel scrap, pig iron, ferrochrome and ferronickel into a vacuum intermediate frequency induction furnace, mix and melt to obtain a mixed solution;

[0037] (2) After the mixed liquid is completely cleared, the temperature is lowered to 1550±10°C, and the temperature is kept for 10-12min to obtain the alloy liquid;

[0038] (3) Add ferroboron, ferrosilicon and ferrotitanium into the alloy liquid, heat up to 1580±10°C, and roll for about 2 minutes to obtain molten steel;

[0039] (4) Controlling the temperature of the molten steel at 1530-1550° C., casting it into a preheated cast iron mold, and demoulding to obtain an iron-based composite material.

[0040] In fact, electromagnetic stirring is always applied during the above-mentioned melting process, so as to ensure uniform alloy composition and uniform dispersion of in-situ-generated ceram...

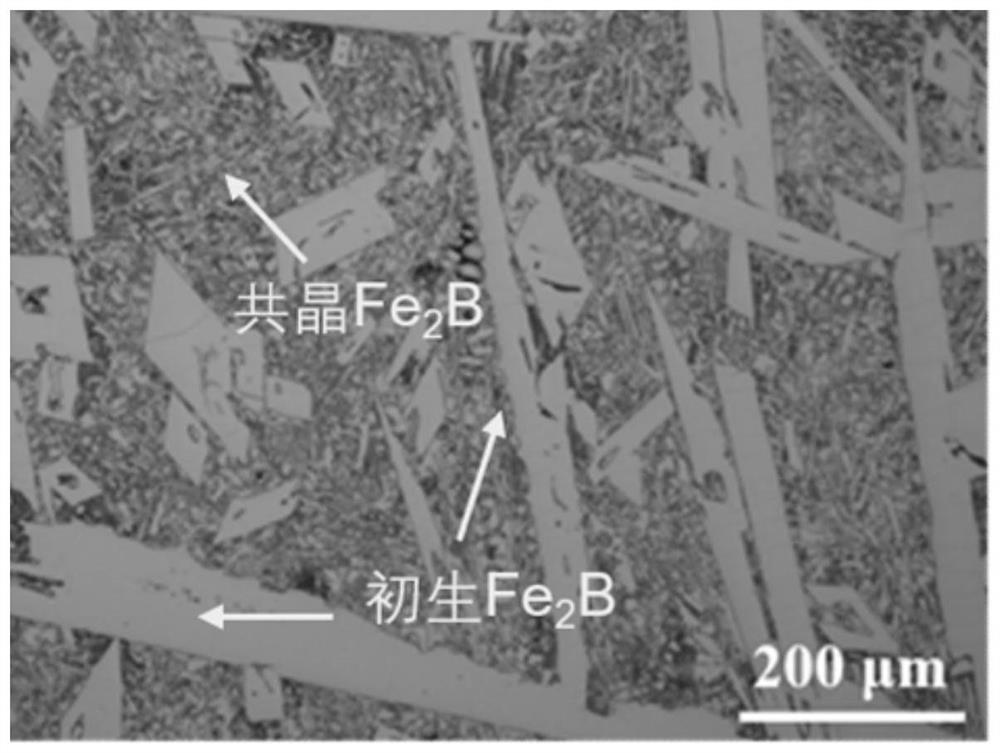

Embodiment 1

[0049] The iron-based composite material of the present embodiment comprises the following components:

[0050] 0.35wt% C, 3.5wt% B, 12.0wt% Cr, 0.7wt% Ti, 0.5wt% Ni, 2.0wt% Si, the balance being Fe.

[0051] The preparation method of the iron-based composite material of the present embodiment comprises the following steps:

[0052] (1) Add steel scrap, pig iron, ferrochrome and ferronickel into a vacuum intermediate frequency induction furnace, mix and melt to obtain a mixed solution;

[0053] (2) After the mixed liquid is completely cleared, the temperature is lowered to 1550°C, and the temperature is kept for about 10 minutes to obtain the alloy liquid;

[0054] (3) Add ferroboron, ferrosilicon and ferrotitanium into the alloy liquid, heat up to 1580°C, and roll for about 2 minutes to obtain molten steel;

[0055] (4) Control the temperature of the molten steel at 1530° C., pour it into a preheated cast iron mold, and demold it to obtain an iron-based composite material. ...

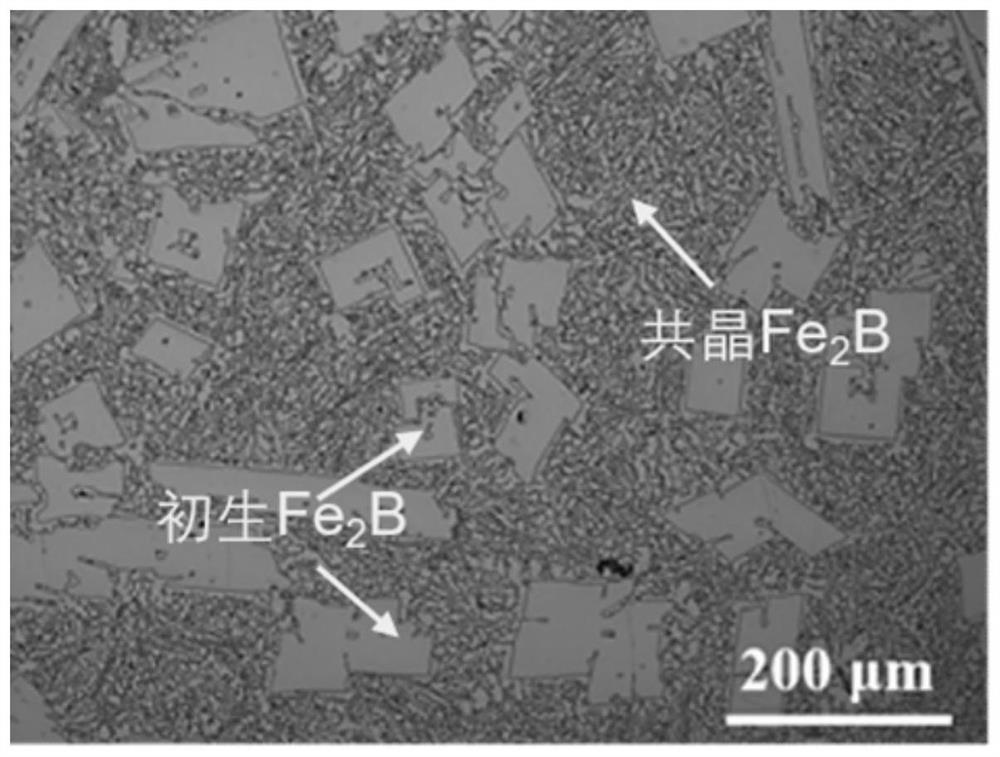

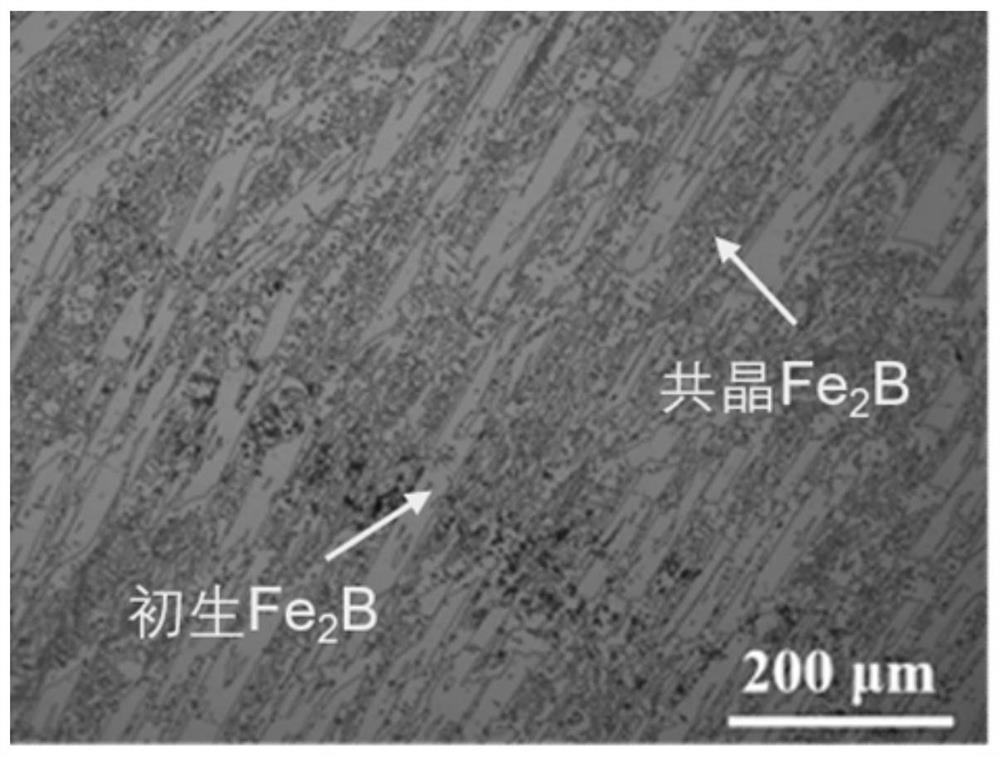

Embodiment 2

[0057] The content of added Ti element is 1.4wt%, and the content and preparation method of other components are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com