Flexible light composite film

A composite film and light technology, applied in optics, filters, optical components, etc., can solve the problems of high-energy short-wave eye damage, inability to filter high-energy short-wave blue light, etc., to reduce eye irritation, ensure high light transmission effect, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

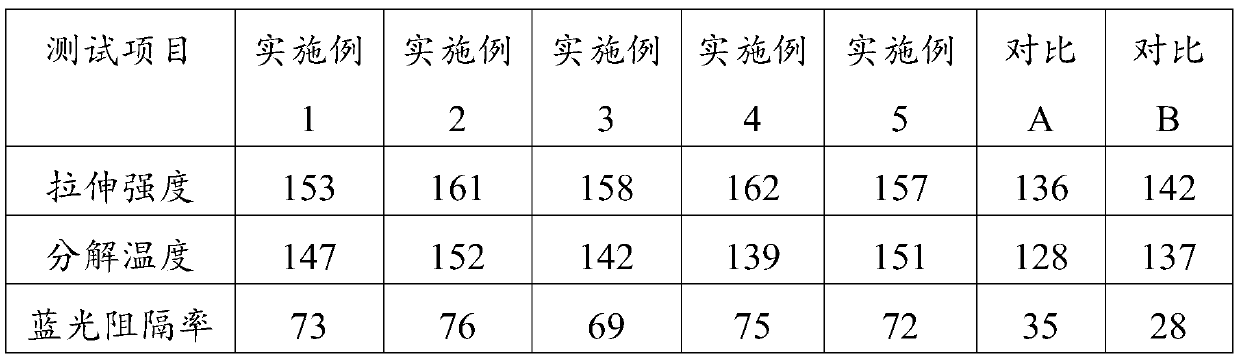

Examples

Embodiment 1

[0022] A flexible light composite film, wherein the composite film has a four-layer structure from top to bottom, which are: the first cladding layer, the protective base layer, the filter base layer and the second clad layer; There is also a cover coating on the side; a self-adhesive layer is also provided between the filter base layer and the inner side of the second coating layer, and the self-adhesive layer is used to attach the protective base layer and the light filter base layer to the surface of the screen that needs to be covered .

[0023] The protective base layer is a PET composite material layer mixed with nano-titanium dioxide particles and nano-zirconia particles, wherein the addition of nano-titanium dioxide and zirconium dioxide is 5% of the mass ratio of polyethylene terephthalate raw materials, and titanium dioxide The mass ratio added to zirconium dioxide is 1:1.

[0024] Preferably, the filter base layer includes the following raw materials in weight frac...

Embodiment 2

[0035] A flexible light composite film, wherein the composite film has a four-layer structure from top to bottom, which are: the first cladding layer, the protective base layer, the filter base layer and the second clad layer; There is also a cover coating on the side; a self-adhesive layer is also provided between the filter base layer and the inner side of the second coating layer, and the self-adhesive layer is used to attach the protective base layer and the light filter base layer to the surface of the screen that needs to be covered .

[0036] Specifically, the protective base layer is a PET composite material layer mixed with nano-titanium dioxide particles and nano-zirconia particles, wherein the addition of nano-titanium dioxide and zirconium dioxide is 4% of the polyethylene terephthalate raw material mass ratio , and the mass ratio of titanium dioxide and zirconium dioxide added is 1:1.

[0037] Preferably, the filter base layer includes the following raw materials...

Embodiment 3

[0048] A flexible light composite film, wherein the composite film has a four-layer structure from top to bottom, which are: the first cladding layer, the protective base layer, the filter base layer and the second clad layer; There is also a cover coating on the side; a self-adhesive layer is also provided between the filter base layer and the inner side of the second coating layer, and the self-adhesive layer is used to attach the protective base layer and the light filter base layer to the surface of the screen that needs to be covered .

[0049] Specifically, the protective base layer is a PET composite material layer mixed with nano-titanium dioxide particles and nano-zirconia particles, wherein the addition of nano-titanium dioxide and zirconium dioxide is 5% of the polyethylene terephthalate raw material mass ratio , and the mass ratio of titanium dioxide and zirconium dioxide added is 1:1.

[0050] Preferably, the filter base layer includes the following raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com