Flexible-transition high-low-frequency double-pulse MIG welding waveform modulating method and system

A modulation method and high-frequency pulse technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve unfavorable double pulse waveform flexible modulation and fine control, unfavorable welding stability and welding quality, strong electromagnetic interference Oscillation peaks and other problems can be achieved to reduce the phenomenon of broken arc and cold plate top wire, enhance the anti-interference ability, and improve the effect of energy transition form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

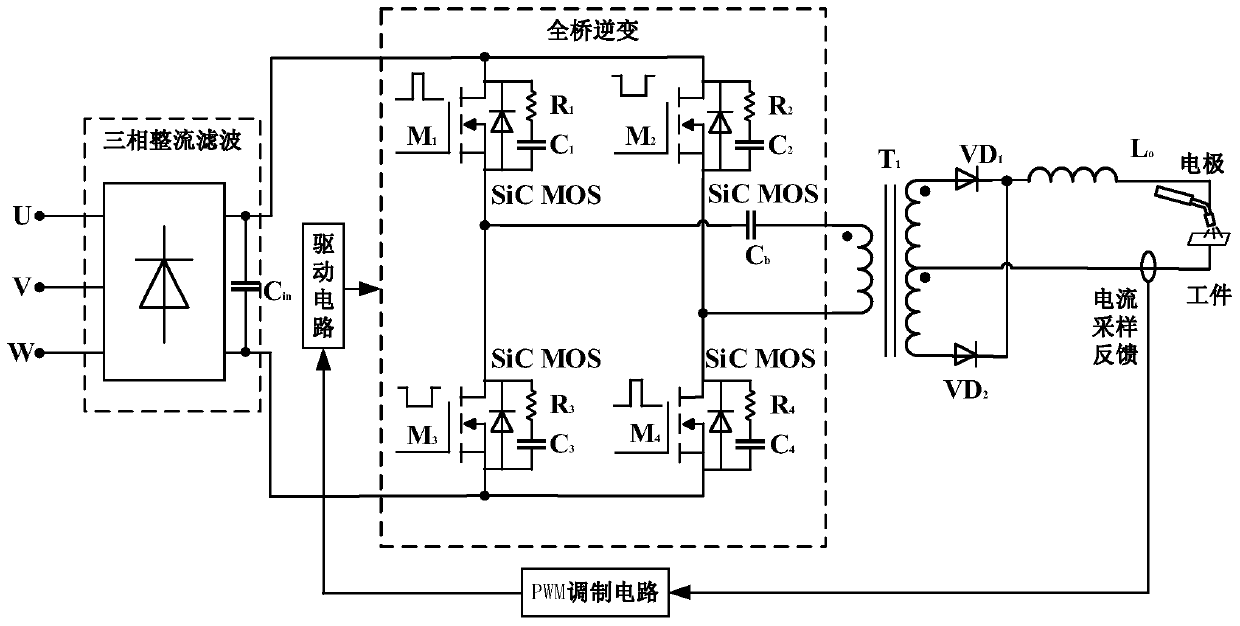

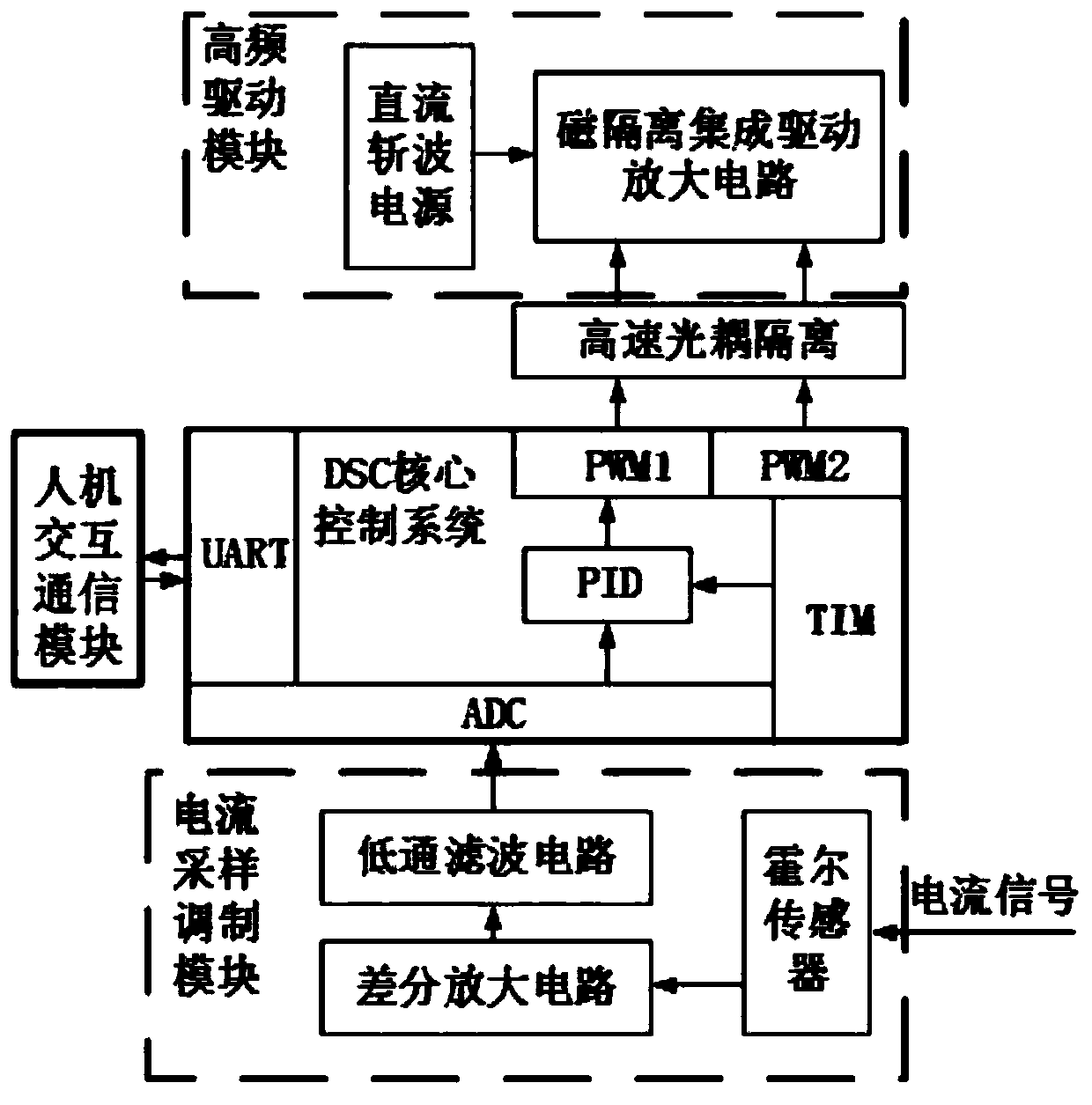

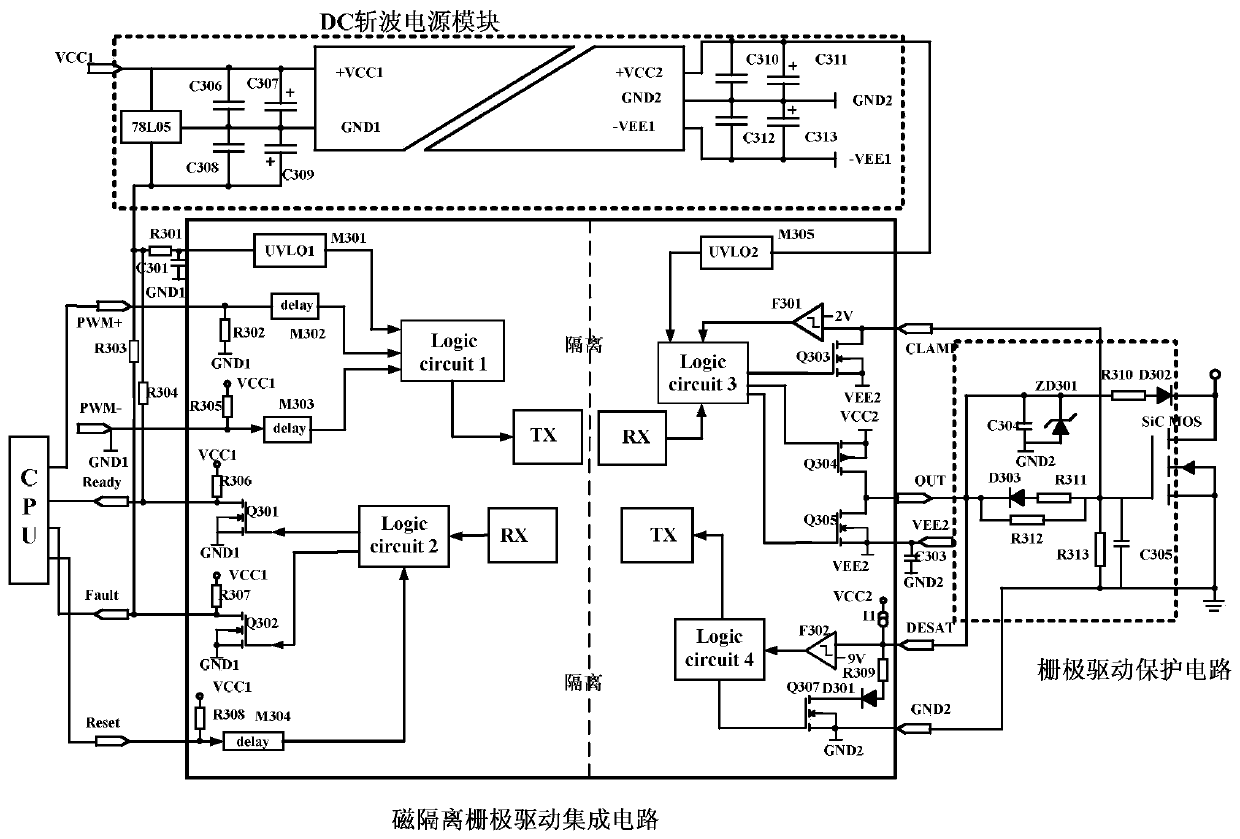

[0042] This embodiment is a flexible transition high-low frequency double-pulse MIG welding waveform modulation method and modulation system. This embodiment uses a high-low frequency double-pulse MIG welding power supply circuit based on SiC power devices as an example for illustration.

[0043] Such as figure 1 As shown, the working principle of the high-low frequency dual-pulse MIG welding power supply circuit based on SiC power devices is: first, the three-phase AC power is converted into DC bus voltage by the three-phase filter and rectifier circuit; the switching tubes M1~M4 in the full-bridge inverter circuit It is a SiC power switch tube. M1, M3, M2, and M4 are alternately driven and turned on by an independent gate drive circuit. The switching frequency is 200kHz, which realizes the inverse conversion of direct current, and transfers the energy to the secondary through the high-frequency transformer T1. Secondary AC power is output through full-wave rectification and ...

Embodiment 2

[0066] This embodiment is a flexible transition high-low frequency dual-pulse MIG welding waveform modulation method and modulation system. This embodiment is applied to a welding power supply based on Si-based power devices; the output end of the SiC high-frequency drive module is connected to the Si-based welding power supply circuit. Power switch tube. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com