Synergistic leaching solution of polycyclic aromatic hydrocarbons and chromium composite polluted soil in electroplating industry and its application

A technology for polycyclic aromatic hydrocarbons and polluted soil, which is applied in the restoration, application, and soil conditioning materials of polluted soil, and can solve the problems of long required period, complicated process, and lack of simultaneous removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

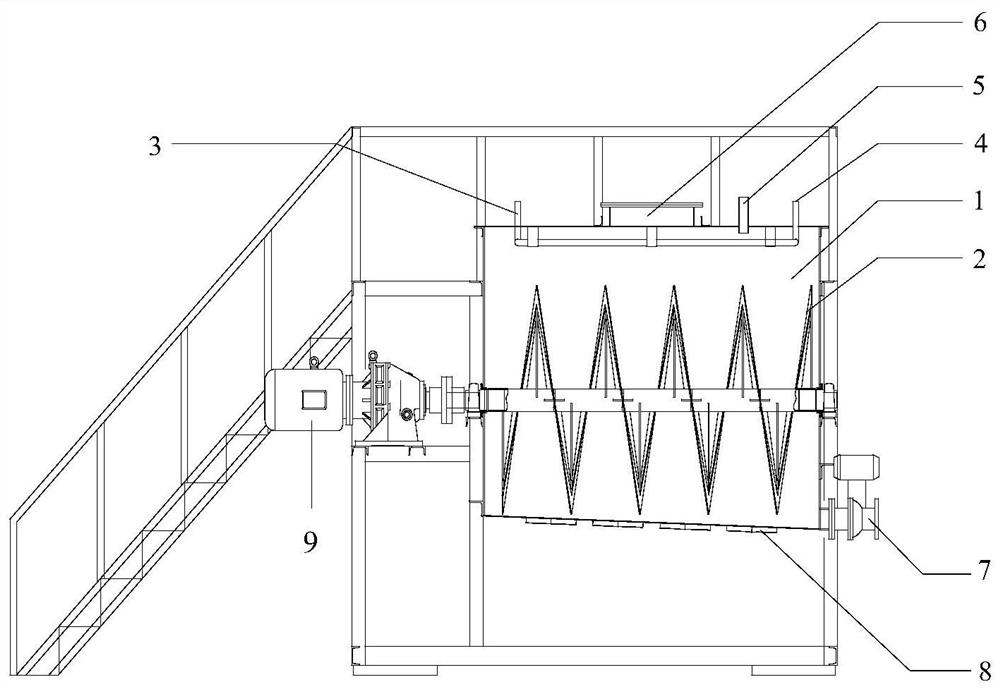

Method used

Image

Examples

Embodiment 1

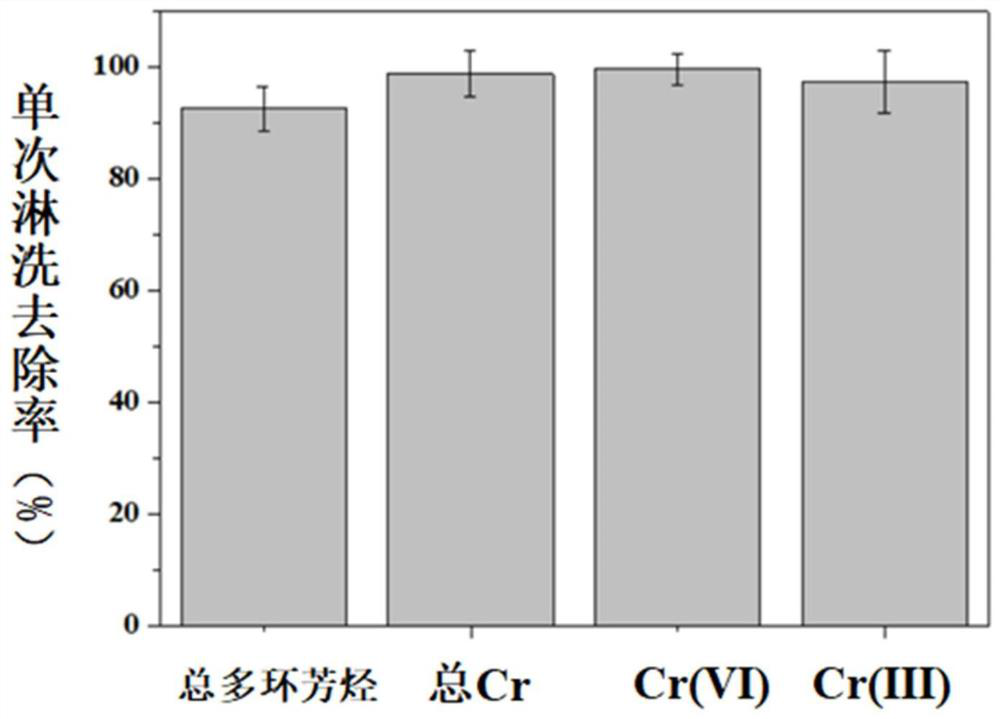

[0038] For total PAH concentration greater than 250 mg kg -1 And less than 5000 mg kg -1 , the total chromium concentration is greater than 30mg kg -1 And less than 100 mg kg -1 The electroplating industry pollutes the site soil:

[0039] The test soil was collected from a polluted site of an electroplating enterprise in Nantong City, Jiangsu Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 6.1, organic matter content 29.1 g kg -1 , total nitrogen 1.8 g kg -1 , available nitrogen 55.2 mg kg -1 , total phosphorus 0.6 g kg -1 , available phosphorus 45.5 mg kg -1 . The mechanical composition of the soil is 15.9 wt.% sand, 64.7 wt.% soil, and 19.4 wt.% clay. The background pollution concentrations of total polycyclic aromatic hydrocarbons, total chromium, hexavalent chromium and trivalent chromium in soil were 492...

Embodiment 2

[0044] For total PAH concentration greater than 5000 mg kg -1 And less than 10000 mg kg -1 , the total chromium concentration is greater than 100 mg kg -1 And less than 1000 mg kg -1 The electroplating industry pollutes the site soil:

[0045] The test soil was collected from a polluted site of an electroplating enterprise in Changxing City, Zhejiang Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 5.8, organic matter content 16.3 g kg -1 , total nitrogen 1.5 g kg -1 , available nitrogen 16.7 mg kg -1 , total phosphorus 0.2 g kg -1 , available phosphorus 24.3 mg kg -1 . The mechanical composition of the soil is 13.3 wt.% sand, 61.4 wt.% loam, and 25.3 wt.% clay. The background pollution concentrations of total polycyclic aromatic hydrocarbons, total chromium, hexavalent chromium and trivalent chromium in soil ...

Embodiment 3

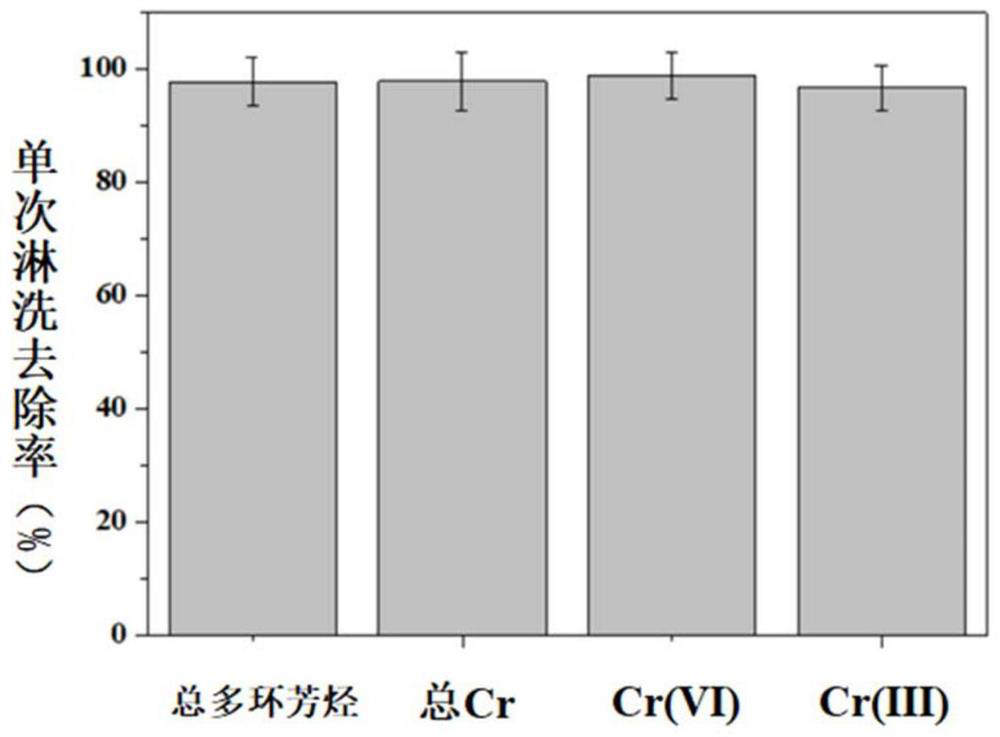

[0050] For the total PAH concentration greater than 10000 mg kg -1 , the total chromium concentration is greater than 1000 mg kg -1 The electroplating industry pollutes the site soil:

[0051] The test soil was collected from a polluted site of an electroplating enterprise in Bengbu City, Anhui Province. The soil samples were air-dried, the impurities were sorted out, and the soil samples were passed through a 10-mesh sieve for later use. The basic physical and chemical properties of the soil are pH 6.2, organic matter content 22.1 g kg -1 , total nitrogen 2.4 g kg -1 , available nitrogen 65.7 mg kg -1 , total phosphorus 0.2 g kg -1 , available phosphorus 18.4 mg kg -1 . The soil mechanical composition is 11.3 wt.% sand, 56.6 wt.% loam, and 32.1 wt.% clay. The background pollution concentrations of total polycyclic aromatic hydrocarbons, total chromium, hexavalent chromium and trivalent chromium in soil were 14468.4 ± 1263.6 mg kg -1 , 2369.1 ± 243.2 mg kg -1 , 2176....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com