Waste incineration energy-saving flue gas ultralow purification system

A waste incineration and purification system technology, applied in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of reducing the efficiency of the whole plant and wasting energy, and achieve high-grade energy saving, high operating costs, and reduced consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

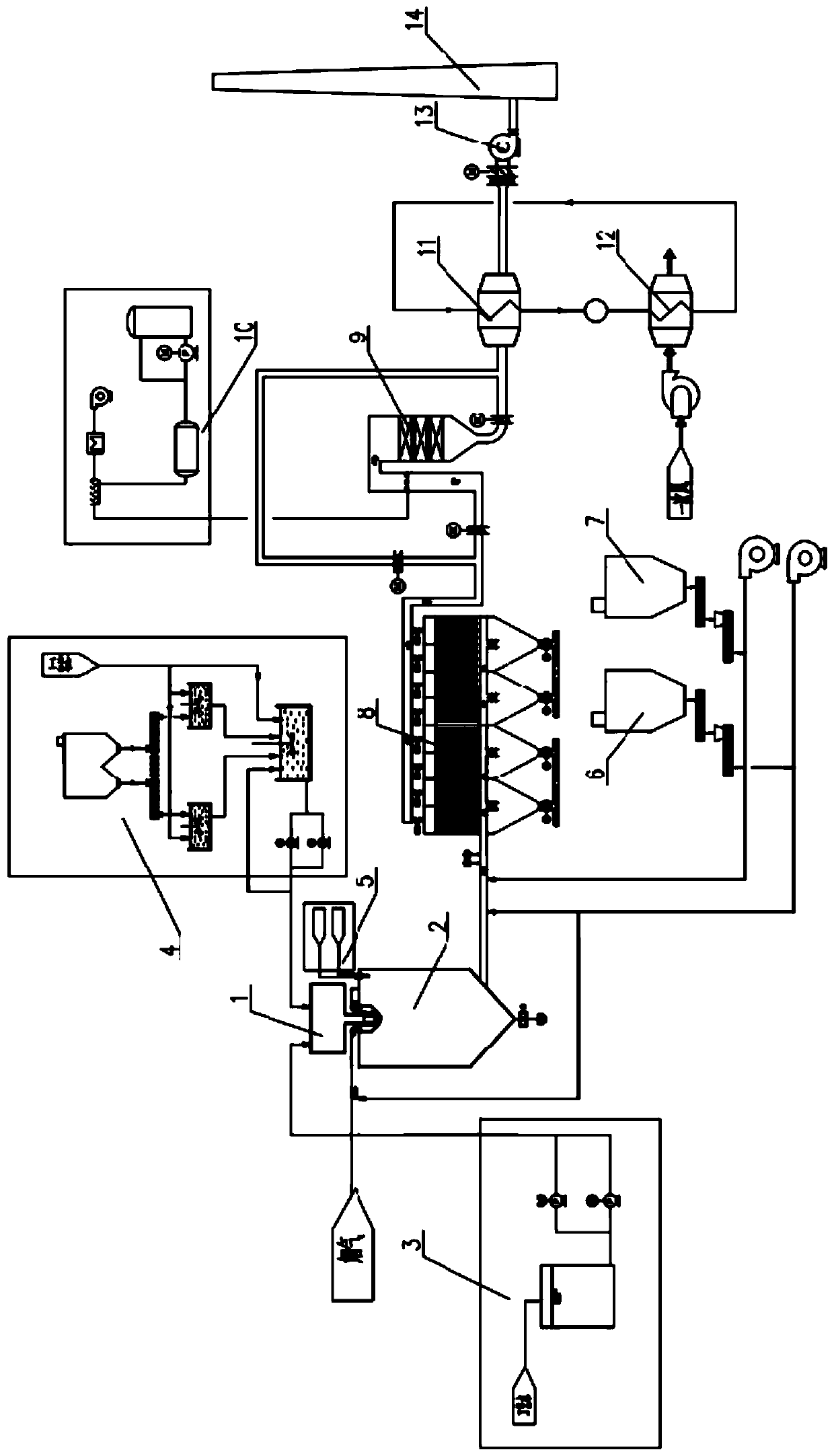

[0038] The present invention is a waste incineration energy-saving flue gas ultra-low emission system, and its system flow chart is as follows figure 1 As shown, it includes SNCR denitrification device (not shown in the schematic diagram, which belongs to furnace denitrification), semi-dry reaction tower 2, sodium carbonate slurry system 4, atomizer cooling water system 3, two-fluid atomization cooling water system 5, carbonic acid Hydrogen and sodium dry powder injection device 6, activated carbon injection device 7, bag filter 8, SCR reactor 9, ammonia water storage and injection device 10, water medium flue gas cooler 11 (also known as: MGGH11), water medium flue gas Heater 12 (also known as MGGH12), induced draft fan 13, chimney 14. The upper part of the semi-dry reaction tower 2 is provided with a high-speed rotary sprayer 1, and the rotary sprayer 1 is connected with a sodium carbonate slurry system 4 and an atomizer cooling water system 3. The top of the semi-dry reacti...

Embodiment 1

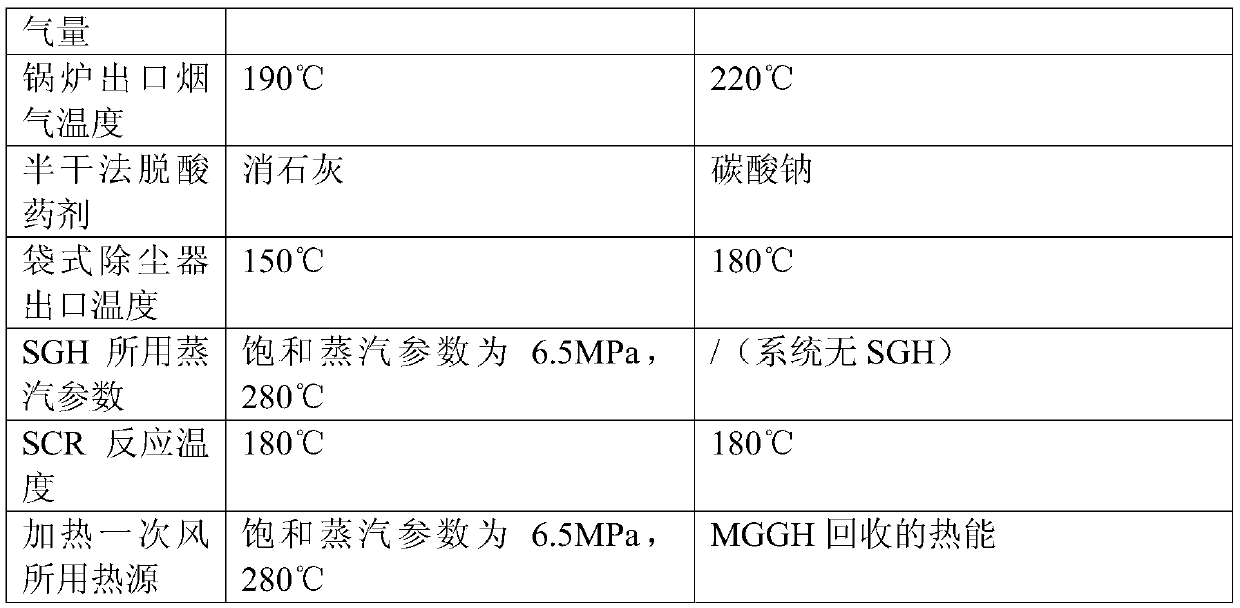

[0045] Taking a waste incineration power plant as an example, with the flue gas combined treatment process of "semi-dry deacidification + dry deacidification + activated carbon adsorption + bag filter + SGH + SCR" using the existing technology, the pollutant discharge meets Standard requirements are compared under the same premise. The basic design parameters are shown in the table below.

[0046]

[0047]

[0048] Under the condition that the emission index meets the requirements of environmental protection, the energy-saving combined process of "SNCR+semi-dry method (sodium carbonate)+dry method (sodium bicarbonate)+activated carbon adsorption+bag filter+SCR+MGGH" of the present invention is adopted, which not only ensures The flue gas emission meets the standard, and the energy consumption can be reduced, and the thermal efficiency of the whole plant can be increased by 0.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com