Liquid metal battery positive electrode current collector with metal carbide coating with concave-convex surface microstructure

A technology for liquid metal batteries and positive current collectors, applied in battery electrodes, active material electrodes, electrode carriers/collectors, etc., can solve problems such as unfavorable technology popularization and application, loss of graphite lining, wear of graphite lining, etc., to achieve Improve electrical conductivity and liquid metal wear resistance, ensure stability and safety performance, and improve wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A liquid metal battery cathode current collector with a concave-convex surface microstructure carbide coating, the preparation method of which comprises the following steps:

[0040] 1) Using NaF-KF-Na 2 CO 3 -Li 2 MoO 4 Molten electrolyte: weigh a total of 500g of NaF-KF with a molar ratio of 2:3, and add 15g of NaF 2 CO 3 and 25g Li 2 MoO 4 , put it in an alumina crucible, put it in a 300°C drying oven for 48 hours to remove the moisture, take it out and put it in a high-temperature resistance furnace, and heat it up to 780°C at a rate of 3°C / min for 2 hours under the protection of an argon atmosphere. molten electrolyte;

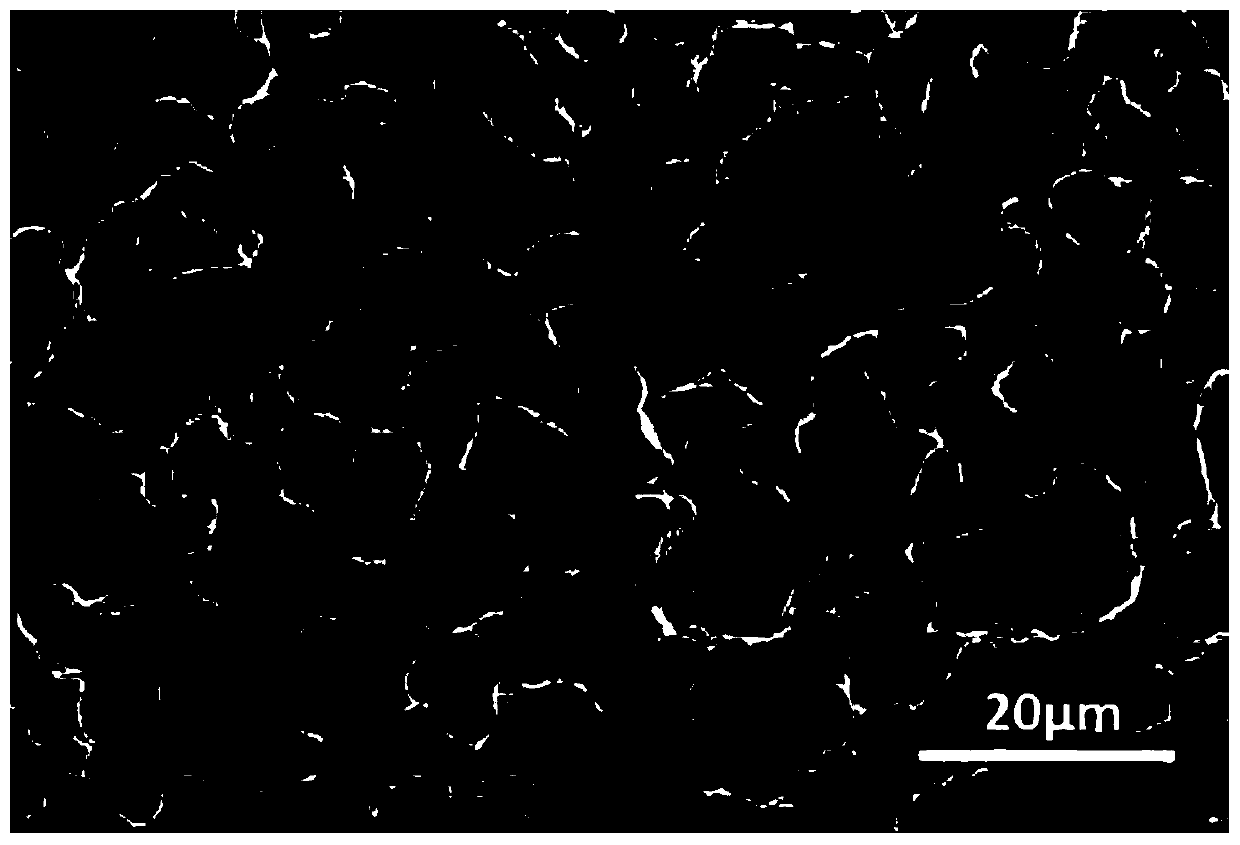

[0041]2) Using SS304 as the cathode and molybdenum sheet as the anode, under the condition of molten electrolyte, electrolyze with a 2.5V cell voltage for 3 hours. After the electrolysis, lift the electrode out until it cools down, and then wash it with water to obtain a microstructure with spherical protrusions. Molybdenum carbide-coated l...

Embodiment 2

[0045] A liquid metal battery cathode current collector with a concave-convex surface microstructure carbide coating, the preparation method of which comprises the following steps:

[0046] 1) Using NaCl-KCl-Li 2 CO 3 -Na 2 WO 4 Molten electrolyte: weigh a total of 500g of NaCl-KCl with a molar ratio of 1:1, and add 15g of Li 2 CO 3 and 25g Na 2 WO 4 , put it in an alumina crucible, put it in a 200°C drying oven for 24 hours to remove the moisture, take it out and put it in a high-temperature resistance furnace, and heat it up to 850°C at a rate of 4°C / min for 2 hours under the protection of an argon atmosphere. molten electrolyte;

[0047] 2) Using SS430 as the cathode and tungsten sheet as the anode, under the condition of molten electrolyte, electrolyze with a 2.0V cell voltage for 2 hours. After the electrolysis, lift the electrode out until it cools down, and then wash it with water to obtain a microstructure with spherical protrusions. Tungsten carbide coated liq...

Embodiment 3

[0051] A liquid metal battery cathode current collector with a concave-convex surface microstructure carbide coating, the preparation method of which comprises the following steps:

[0052] 1) Using NaF-KF-LiF-Li 2 CO 3 -K 2 CrO 4 Molten electrolyte: weigh a total of 500g of NaF-KF-LiF with a mass ratio of 30:60:10, and add 15g of Li 2 CO 3 and 25g K 2 CrO 4 , mixed well, put it in an alumina crucible, put it in a 250°C drying oven for 24 hours to remove the moisture, take it out and put it in a high-temperature resistance furnace, and under the protection of an argon atmosphere, heat it up to 950°C at a rate of 4°C / min and keep it for 2h. molten electrolyte;

[0053] 2) With SS430 as the cathode and Cr sheet as the anode, under the condition of molten electrolyte, 150mA cm -2 The current density of the electrolysis is 3h. After the electrolysis is over, the electrode is taken out until it is cooled, and then washed with water to obtain a liquid metal battery positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com