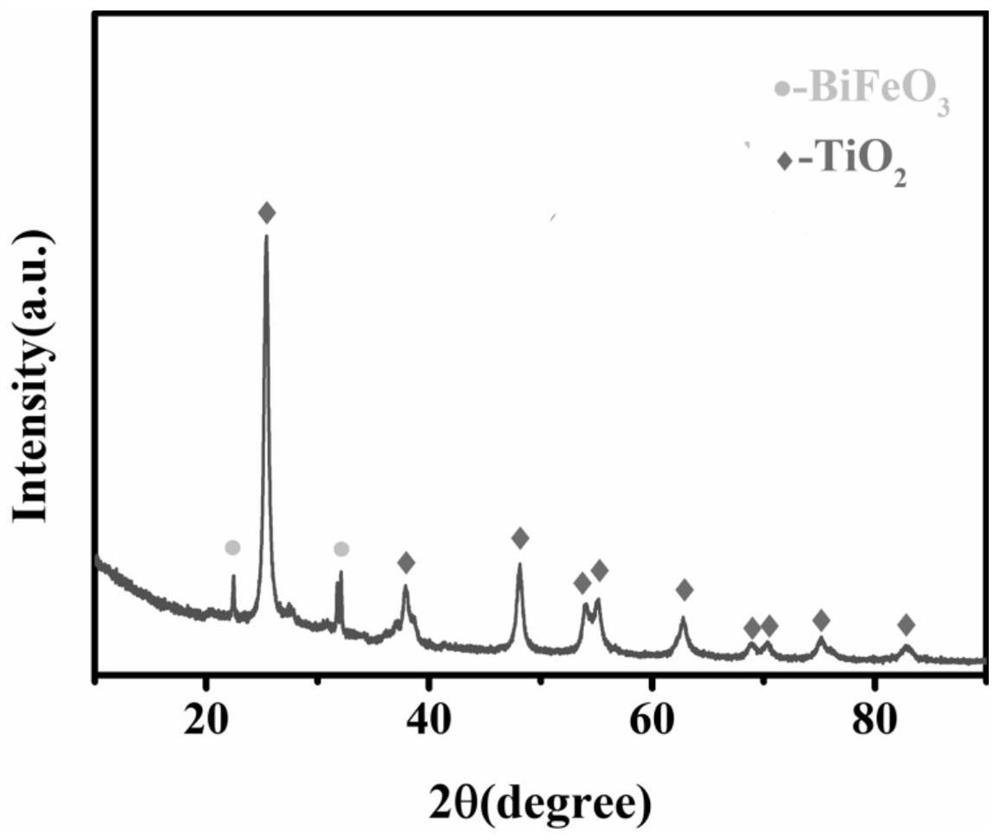

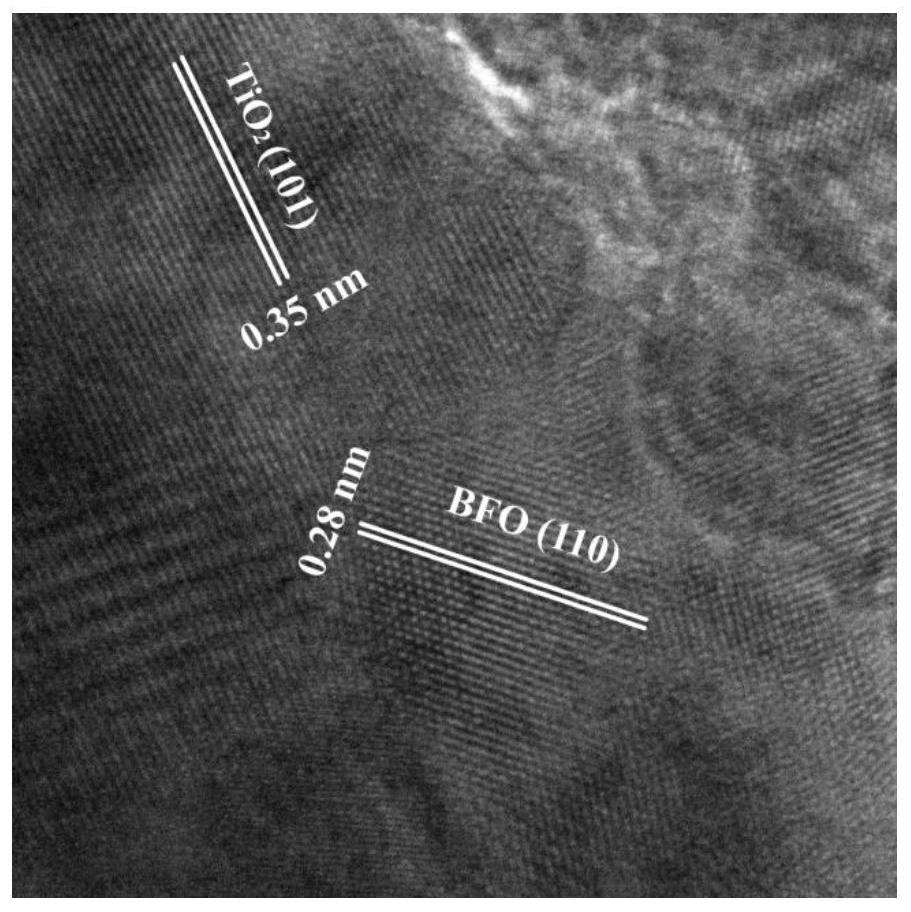

Bismuth ferrite@titanium dioxide composite material for lithium-sulfur battery diaphragm and preparation method

A lithium-sulfur battery and composite material technology, applied in the direction of titanium dioxide, iron compounds, chemical instruments and methods, etc., can solve the problems of inability to inhibit the shuttle of polysulfides, the inability to effectively inhibit the shuttle effect, and the single function of the polypropylene diaphragm. Generation of heterogeneous phases, reduction of shuttling effects, effects of multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

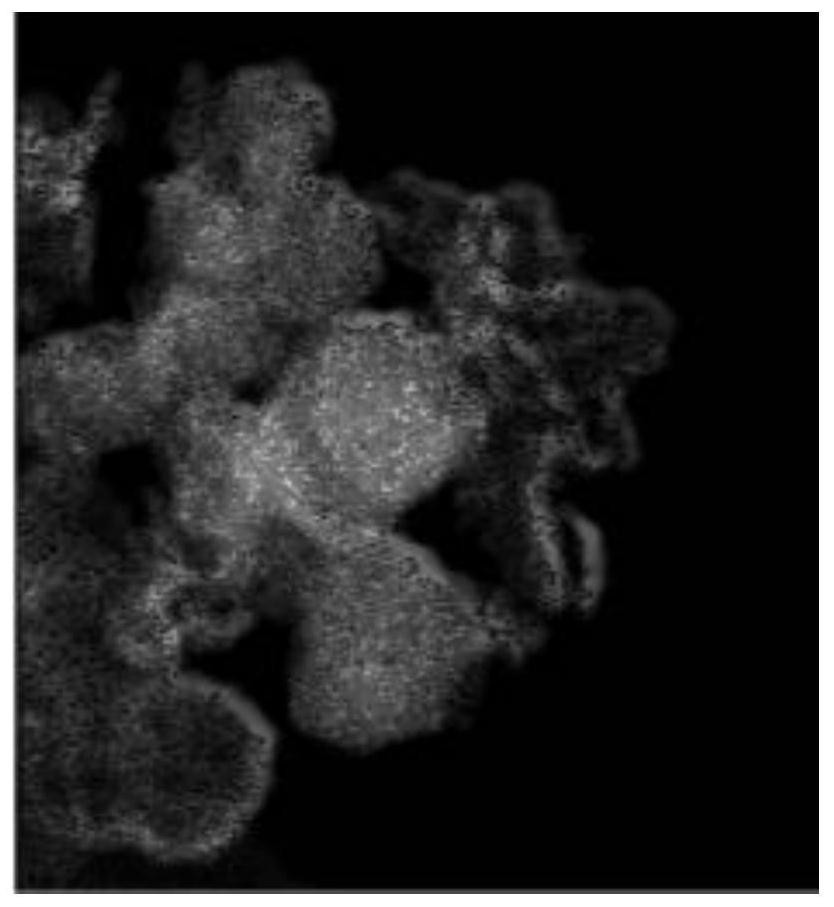

Method used

Image

Examples

Embodiment 1

[0031] A method of preparing a lithium sulfur battery diaphragm based on a bismuth / titanium dioxide composite material, specifically comprising the steps of:

[0032] Step 1, kethale isopropyl titanate is added to ethanol, and the solution A is obtained at 60 ° C for 10 min, then the solution A is obtained, and then a diameter of 150 nm is added to the solution A and stir evenly to obtain a mixed solution B; wherein the solution A is The volume ratio of isopropyl titanate and ethanol is 0.05: 1, and the concentration of carbon ball in the mixed solution B is 1 mg / ml;

[0033] Step 2, the ammonia was added to the mixed solution B, and the reaction was stirred at 60 ° C to obtain a suspension C, centrifuged at 8000 rpm, dried, dried, 3 min in 400 ° C for 30 min, to obtain a white titanium dioxide powder; wherein ammonia water and mixing The volume ratio of solution B was 0.01: 1.

[0034] Step 3, add nitrate, bismuth nitrate, bismuth nitrate, and nitric acid, then add nitric aci...

Embodiment 2

[0043] According to the step of Example 1, a lithium sulfur battery diaphragm based on the bismuth / titanium dioxide composite is prepared, and only the titanate in the step 1 is adjusted to a n-butyl titanate, isopropyl titanate and ethanol in solution A. The ratio is 0.1: 1, the sintering time in step 2 is adjusted to 60 min, and the stirring time in step 3 is adjusted to 12 h, and the other steps are unchanged.

Embodiment 3

[0045] According to the steps of Example 1, a lithium sulfur battery diaphragm based on the bismuth / titanium dioxide composite is prepared, and only the nitrate, bismuth nitrate and nitrate in step 3 are adjusted as iron iron, oxalate and oxalate, organic solvent and nitric acid. Adjusting to ethylene glycol and oxalic acid, the molar ratio of citric acid and iron titrates is 2.2: 1, and other steps are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com