Preparation method of lithium-sulfur battery diaphragm

A technology for lithium-sulfur batteries and diaphragms, which is applied in the field of preparation of lithium-sulfur battery diaphragms, can solve serious problems such as the inability to take into account the shuttle effect, and achieve the effect of taking into account the thickness, suppressing the shuttle effect, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

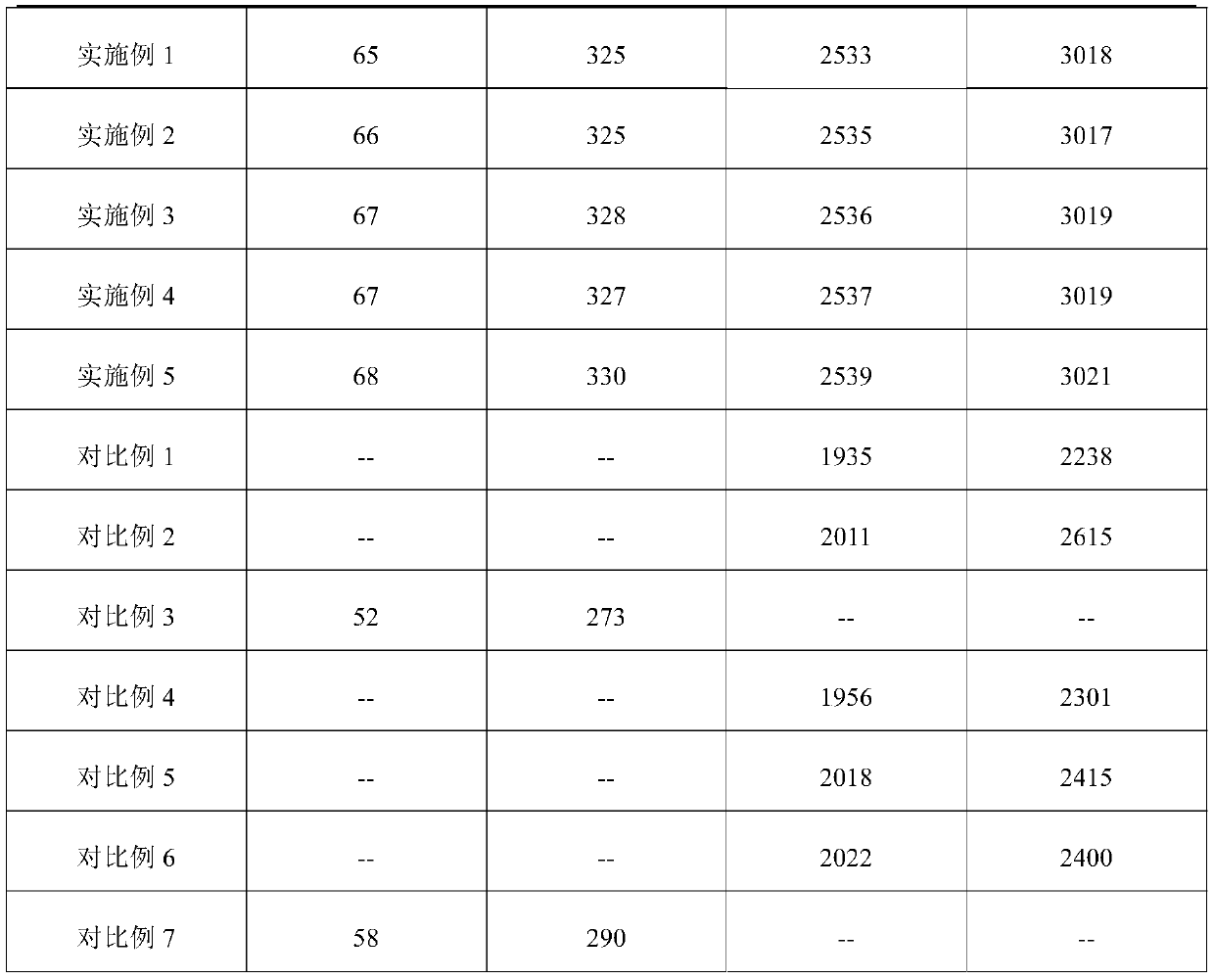

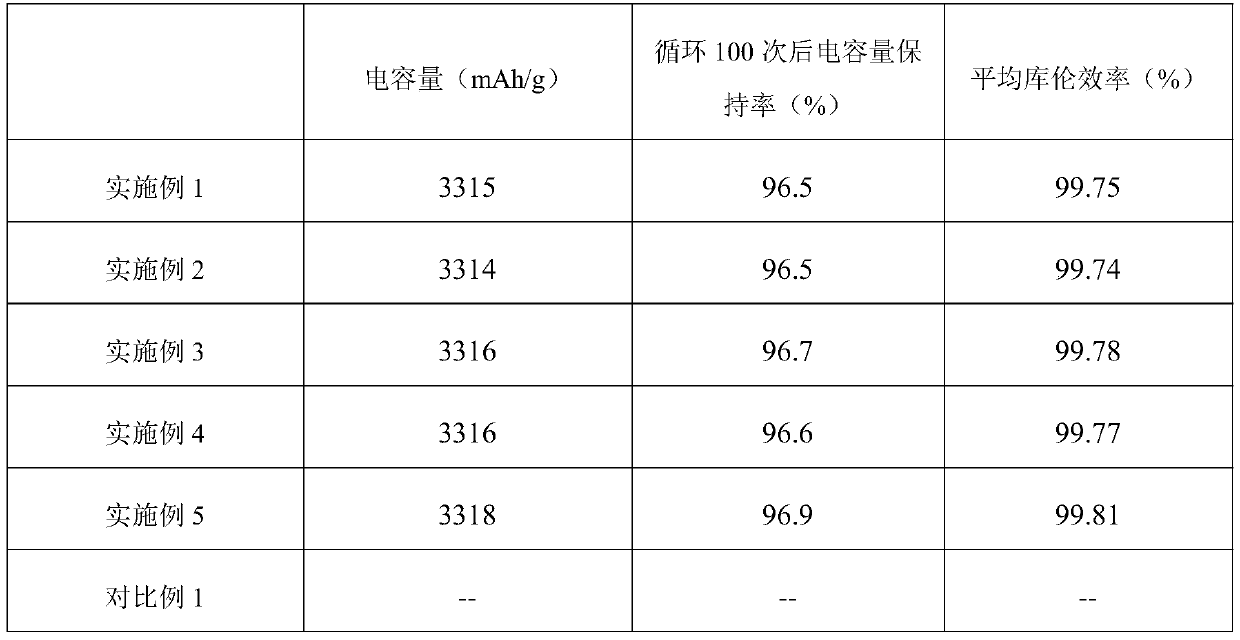

Examples

Embodiment 1

[0034] A preparation method of a lithium-sulfur battery diaphragm, in parts by weight, the specific steps are as follows:

[0035] (1) First blend 1 part of glass fiber, 2.5 parts of polyamide fiber and 0.3 part of water-soluble vinylon fiber into yarn, and weave it into cloth to obtain the base film;

[0036] (2) Next, mix 8 parts of polyurethane fibers, 5 parts of nanocrystalline cellulose, 0.1 parts of carboxypolystyrene microspheres, 0.5 parts of sodium lignosulfonate, and 0.4 parts of tetraethyl orthosilicate into 40 parts of water, and disperse Evenly, the gelatinous slurry is obtained, which is equally divided into two parts, and is uniformly extruded to the two surfaces of the base film obtained in step (1) respectively;

[0037] (3) Coagulate to form a film, extrude, hot press, heat treatment and toluene washing in sequence, and supercritical drying to obtain the lithium-sulfur battery separator (10 μm).

[0038] Preferably, the lithium-sulfur battery separator has a t...

Embodiment 2

[0053] A preparation method of a lithium-sulfur battery diaphragm, in parts by weight, the specific steps are as follows:

[0054] (1) First blend 1 part of glass fiber, 3 parts of polyamide fiber and 0.4 part of water-soluble vinylon fiber into yarn, and weave it into cloth to obtain the base film;

[0055] (2) Next, mix 10 parts of polyurethane fibers, 6 parts of nanocrystalline cellulose, 0.3 parts of carboxypolystyrene microspheres, 0.8 parts of sodium lignosulfonate, and 0.6 parts of tetraethyl orthosilicate into 50 parts of water, and disperse Evenly, the gelatinous slurry is obtained, which is equally divided into two parts, and is uniformly extruded to the two surfaces of the base film obtained in step (1) respectively;

[0056] (3) Coagulate to form a film, extrude, hot-press form, heat treatment and toluene washing in sequence, and supercritical drying to obtain the lithium-sulfur battery separator (12 μm).

[0057] In step (1), the length of the glass fiber is 12 m...

Embodiment 3

[0071] A preparation method of a lithium-sulfur battery diaphragm, in parts by weight, the specific steps are as follows:

[0072] (1) First blend 1 part of glass fiber, 2.5 parts of polyamide fiber and 0.4 part of water-soluble vinylon fiber into yarn, and weave it into cloth to obtain the base film;

[0073] (2) Next, mix 8 parts of polyurethane fibers, 6 parts of nanocrystalline cellulose, 0.1 parts of carboxypolystyrene microspheres, 0.8 parts of sodium lignosulfonate, and 0.4 parts of tetraethyl orthosilicate into 50 parts of water, and disperse Evenly, the gelatinous slurry is obtained, which is equally divided into two parts, and is uniformly extruded to the two surfaces of the base film obtained in step (1) respectively;

[0074] (3) Coagulate to form a film, extrude, hot press, heat treatment and toluene washing in sequence, and supercritical drying to obtain the lithium-sulfur battery separator (10 μm).

[0075] In step (1), the length of the glass fiber is 10 mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com