Carbon nanotube-modified polyolefin double-resistant material and preparation method and application thereof

A carbon nanotube modification and carbon nanotube technology, which is applied in the field of flame retardant and antistatic polyolefin composite materials, can solve the problems of brittle pipes, large amount of flame retardants, poor pressure resistance, etc., and achieves high preparation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

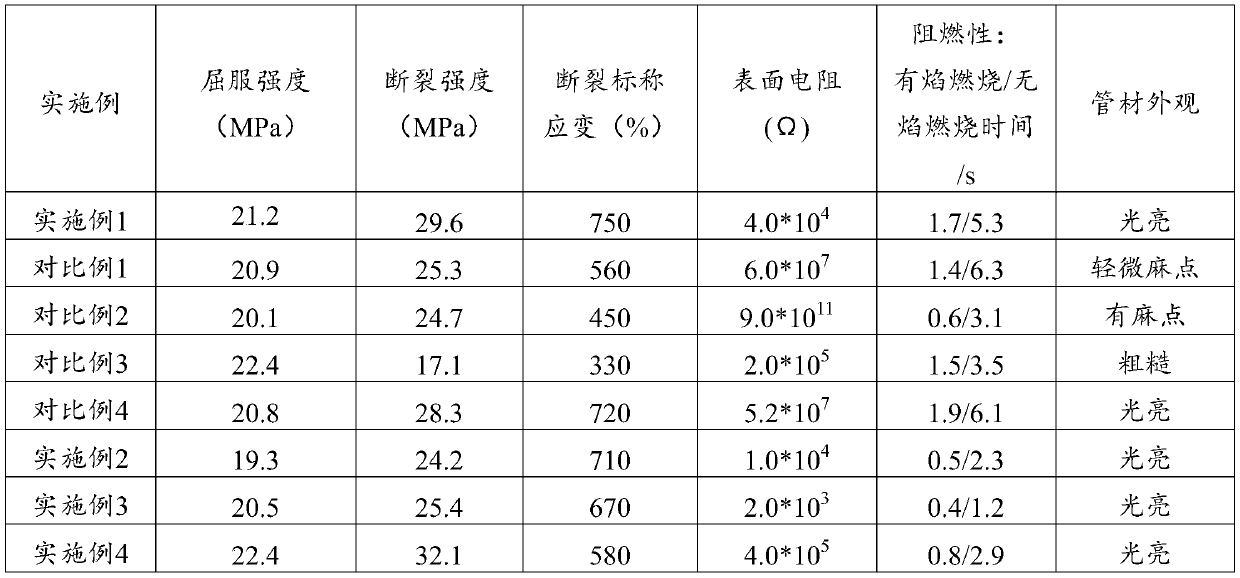

Examples

Embodiment 1

[0040] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional grafting: the polyethylene-octene copolymer (8200, Dow Chemical) of 78.42% by weight, the maleic anhydride of 1.5%, 20% After the polysiloxane and 0.08% organic peroxide dicumyl peroxide are mixed evenly, the bifunctional grafting is carried out at 200-210°C by a twin-screw extruder to obtain maleic anhydride, polysiloxane grafted branched polyolefin elastomer (POE-g-MAH / Si).

[0041] Surface treatment of S1 conductive agent:

[0042] Multi-walled carbon nanotubes (NC7000, Belgium Nanocyl) 3%, superconducting carbon black (Ketjen Black ECP600JD) 2.5%, Add 1.5% of dispersant (6879, Evonik Degussa) into the high mixer, mix at 500rpm for 30min, and discharge for later use.

[0043] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0044] Mix the conductive agent mixture treated with S1 and 50% grade 100 polyethylene pipe material (100S,...

Embodiment 2

[0083] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional graft: the polyethylene-octene copolymer (LC170 of LG chemistry) of weight ratio 50%, 37.95% polyethylene-butene copolymer ( LC565, LG Chemical), 2% of maleic anhydride, 10% of polysiloxane, 0.05% of organic peroxide di-tert-butyl peroxide mixed evenly, using a twin-screw extruder at 230 ℃ for double Functional grafting to obtain maleic anhydride, polysiloxane grafted polyolefin elastomer (POE-g-MAH / Si).

[0084] Surface treatment of S1 conductive agent:

[0085] Single-walled carbon nanotubes (TNSR, Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences) 2%, chopped carbon fibers (length 3mm) 4%, Add 2% of DS 360 dispersant (Yantai Wanhua) into the high mixer, mix at 800rpm for 20min, and discharge for later use.

[0086] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0087] Mix the conductive agent mixture treated with...

Embodiment 3

[0093] The preparation of the polyolefin elastomer of maleic anhydride, polysiloxane bifunctional graft: the polyethylene-vinyl acetate copolymer (3170, Du Pont) of weight ratio 83.98%, 1% maleic anhydride, 15% After polysiloxane and 0.02% organic peroxide 2,5-dimethyl-2,5-di-tert-butylperoxyhexane are mixed uniformly, bifunctional grafting is carried out at 170°C using a twin-screw extruder , to obtain maleic anhydride, polysiloxane grafted polyolefin elastomer (EVA-g-MAH / Si).

[0094] Surface treatment of S1 conductive agent:

[0095] Multi-walled carbon nanotubes (GT210, Shandong Dazhan Nano Material Co., Ltd.) 5%, carbon fiber powder (50 orders) 0.5%, SOLPLUS TM Add 0.8% of K240 dispersant (Lubrizol) into the high mixer, mix at 600rpm for 40min, and discharge for later use.

[0096] Preparation of Conductive Agent / Polyethylene Composite Powder by S2 Rotary Shear Dispersion

[0097] Mix the conductive agent mixture treated with S1 and 40% heat-resistant polyethylene pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com