Composite refractory material based on waste inorganic fiber material and preparation method thereof

A technology of inorganic fiber and refractory materials, applied in the field of composite refractory materials based on waste inorganic fiber materials and its preparation, can solve problems such as environmental pollution and inability to degrade naturally, and achieve scientific and reasonable structural design, low processing cost, fire resistance and heat insulation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

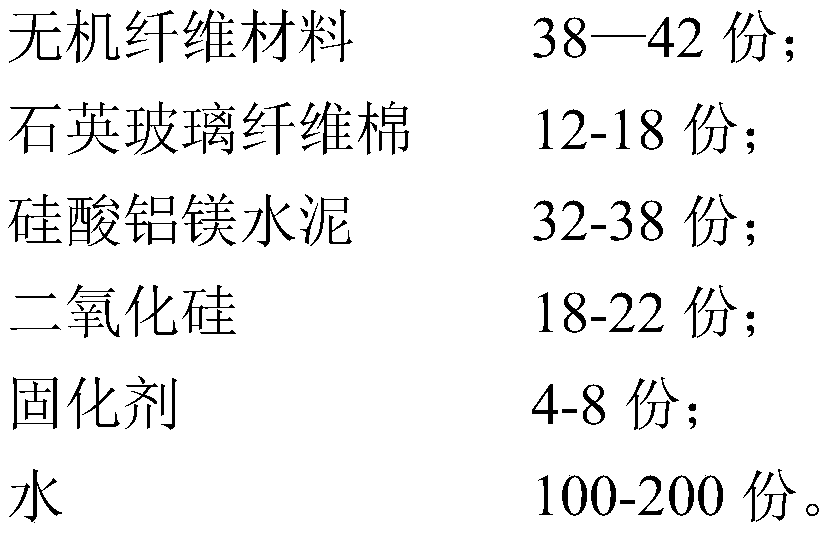

[0019] A composite refractory material based on waste inorganic fiber materials, the innovation of which is that it includes the following components by weight:

[0020]

[0021]

[0022] The inorganic fiber material is magnesium aluminum silicate wool or ceramic fiber cotton.

[0023] The density of the thermal insulation material is 0.1.2~1.8g / cm 3 , the thermal conductivity is 0.032~0.049w·k, and the bearing pressure is 98KN / cm 2 , high temperature resistance is less than or equal to 1200 ℃.

[0024] A method for preparing a composite refractory material based on waste inorganic fiber materials, the innovation of which is that it mainly includes the following steps:

[0025] Step 1: Screening, screening ceramic fiber cotton or aluminum magnesium silicate cotton to remove combustibles, impurities, and garbage to form a clean cotton block;

[0026] Step 2: Breaking, breaking the large clean cotton pieces into 50-mesh small cotton pieces;

[0027] Step 3: First put 1...

Embodiment 2

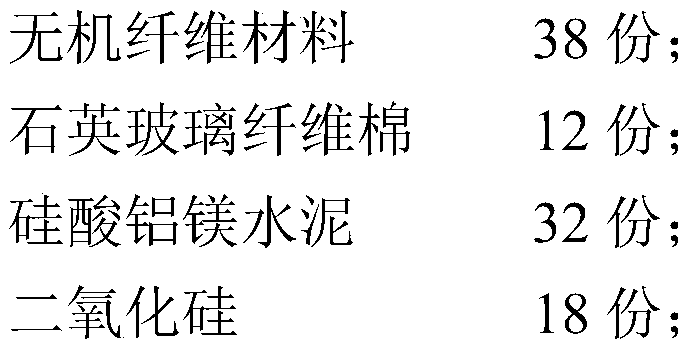

[0030] A composite refractory material based on waste inorganic fiber materials, the innovation of which is that it includes the following components by weight:

[0031]

[0032] The inorganic fiber material is magnesium aluminum silicate wool or ceramic fiber cotton.

[0033] The density of the thermal insulation material is 0.1.2~1.8g / cm 3 , the thermal conductivity is 0.032~0.049w·k, and the bearing pressure is 98KN / cm 2 , high temperature resistance is less than or equal to 1200 ℃.

[0034] A method for preparing a composite refractory material based on waste inorganic fiber materials, characterized in that it mainly includes the following steps:

[0035] Step 1: Screening, screening ceramic fiber cotton or aluminum magnesium silicate cotton to remove combustibles, impurities, and garbage to form a clean cotton block;

[0036] Step 2: Breaking, breaking the large clean cotton pieces into 80-mesh small cotton pieces;

[0037] Step 3: First put 150 parts of water and ...

Embodiment 3

[0040] A composite refractory material based on waste inorganic fiber materials, the innovation of which is that it includes the following components by weight:

[0041]

[0042] The inorganic fiber material is magnesium aluminum silicate wool or ceramic fiber cotton.

[0043] The density of the thermal insulation material is 0.1.2~1.8g / cm 3 , the thermal conductivity is 0.032~0.049w·k, and the bearing pressure is 98KN / cm 2 , high temperature resistance is less than or equal to 1200 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com