Fabric concrete block and preparation method

A technology for concrete blocks and fabrics, which is used in the manufacture of tools, building materials, ceramic molding machines, etc., can solve the problems of hollow surface plastering, low block strength, and easy cracking of the wall, so as to achieve the adsorption force of the wall, reduce the The effect of water absorption, improved frost resistance and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

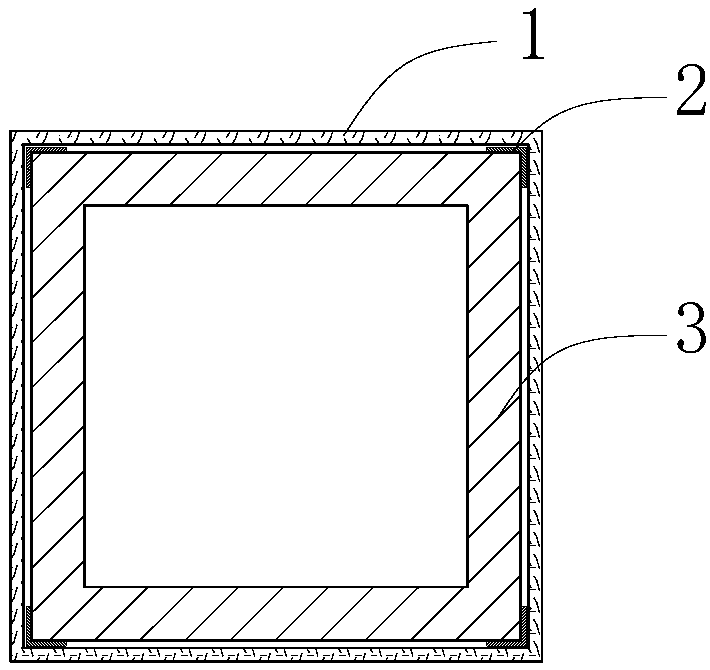

[0038] The invention discloses a fabric concrete block and a preparation method thereof, comprising the preparation of a fabric shell, filling the fabric shell 1 into the shell and curing and molding. The size and shape of the blocks involved in the present invention are not limited, and can be conventional sizes or custom sizes. Specifically, the following steps are included.

[0039] 1) Preparation of the fabric shell 1: prepare a core tube 3, the inner space of the core tube 3 is consistent with the shape of the block, the cross-sectional size of the core tube 3 is slightly smaller than the cross-sectional size of the block, the length of the core tube 3 is consistent with the length of the block, and Tube 3 is wrapped with a plastic film.

[0040] 2) Fix the L-shaped corner strip 2 on the four edges of the core tube 3 with double-sided tape, and paint the mixture of epoxy resin and curing agent on the outside of the L-shaped corner strip 2.

[0041] 3) Paste the starting...

example 1

[0047] A fabric concrete block and a preparation method thereof, comprising the following steps

[0048] 1. Preparation of the core barrel 3: Prepare the steel core barrel 3 and wrap it with a layer of plastic film. The cross-sectional dimension of the core barrel 3 is slightly smaller than the cross-sectional dimension of the block, and the length is the same as that of the block.

[0049] 2. Paste the L-shaped corner strip 2 on the four edges of the core tube 3 with double-sided tape. The L-shaped corner strip 2 shares one edge to ensure that the corners of the block are at right angles. The L-shaped corner strip 2 is coated with epoxy resin and curing agent mixture.

[0050]3. Paste the starting edge of the fabric 1 on one side of the L-shaped corner strip 2 on the edge of the core tube 3, and wrap it around the core tube 3 for a week, stick it on the L-shaped corner strip 2 on each edge in turn, and finally close it on the same edge The other face of the L-shaped corner b...

example 2

[0055] A fabric concrete block and a preparation method thereof, comprising the following steps

[0056] 1. Preparation of the core barrel 3: Prepare the core barrel 3 and wrap it with a layer of plastic film. The cross-sectional dimension of the core barrel 3 is slightly smaller than the cross-sectional dimension of the block, and the length is the same as that of the block.

[0057] 2. Paste the L-shaped corner strip 2 on the four edges of the core tube 3 with double-sided adhesive tape. The L-shaped corner strip 2 shares one edge to ensure that the corner of the block is at a right angle. The L-shaped corner strip 2 is coated with epoxy resin and curing agent mixture.

[0058] 3. Paste the starting edge of the fabric 1 on one surface of the L-shaped corner strip 2 on the edge of the core tube 3, and wrap around the core tube 3 for a week, and stick it to the L-shaped corner strips 2 on each edge in turn, and finally close on the same edge The other side of the L-shaped cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com