Pan stand and manufacture method thereof

A production method and a technology of a pot stand, which are applied in the field of kitchen stoves, can solve the problems of high cost, unfavorable market competition, and high overall price of gas stoves, and achieve the effects of saving production costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

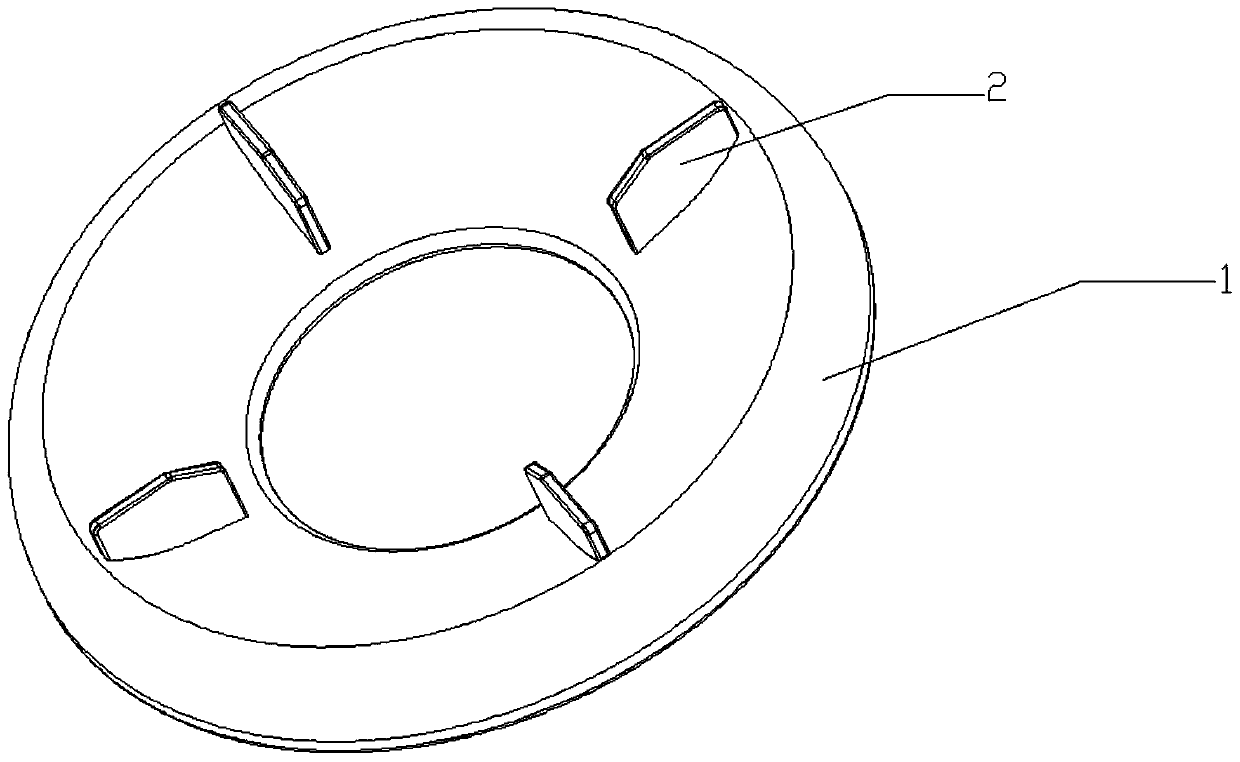

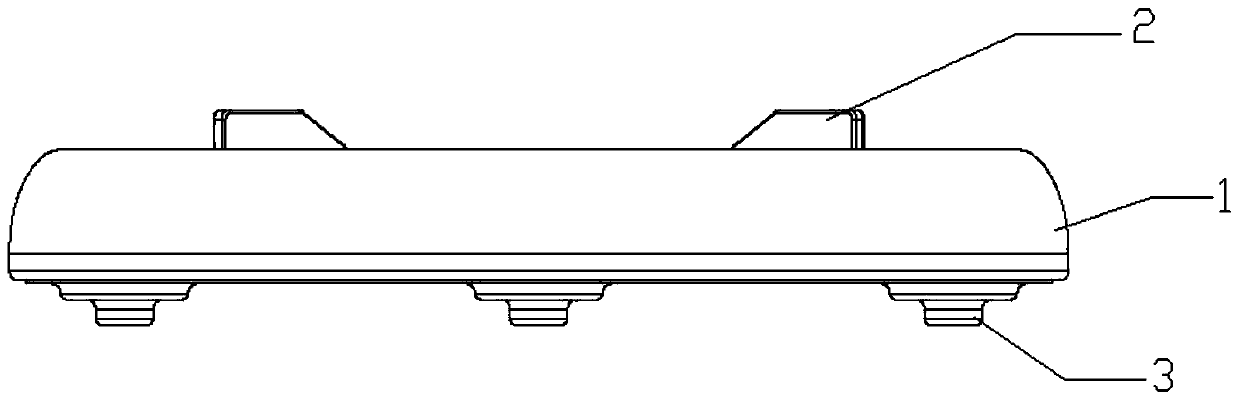

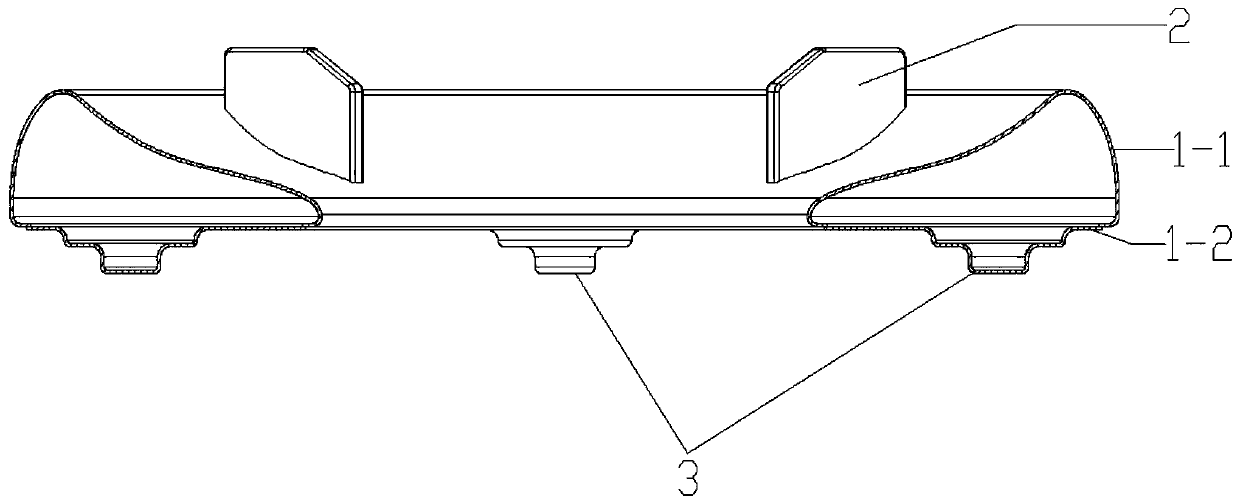

[0039] Such as figure 1 , 2 , Shown in 6, a kind of pot stand of the present invention and manufacturing method thereof, the steps comprise:

[0040] In the first step, the SPCC cold plate material 6 is stretched in the mold to form the upper cover plate 1-1 and the lower cover plate 1-2 structure of the pot stand, wherein the upper cover plate 1-1 and the lower cover plate 1-2 are both It is a ring structure, and the two are covered to form a hollow heat-insulating cavity; during the molding process of the upper cover plate 1-1, four mounting positions for the corner pieces 2 are provided on the circumference of the upper cover plate 1-1, and the corner pieces 2 The plug is fixed in the installation position, and then the connection is welded as a whole, and the welding part is polished and polished evenly. Such as image 3 As shown, the lower cover plate 1-2 is stretched to form a stand structure 3 during the molding process. In this embodiment, the stand structure 3 is f...

Embodiment 2

[0050] A pot support made of composite material, the manufacturing method is the same as that described in the embodiment. In this embodiment, the pot support is installed on the liquid receiving pan of the gas stove.

[0051] It should be noted that, in addition to the specific examples given above, some of the structures may have different choices. For example, when using a spray gun to spray ceramic coatings, the diameter of the spray gun can be within 0.8-1.4mm; and these are all those skilled in the art can make based on their basic skills on the basis of understanding the idea of the present invention, so here No more examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com