Etomidate nano preparation and preparation method thereof

A technology of etomidate and nano-preparation, applied in nanotechnology, nanotechnology, nanomedicine and other directions, can solve the problems of unusable and unfavorable preservation of nutrients, and achieve the effects of easy storage, non-irritant allergy and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

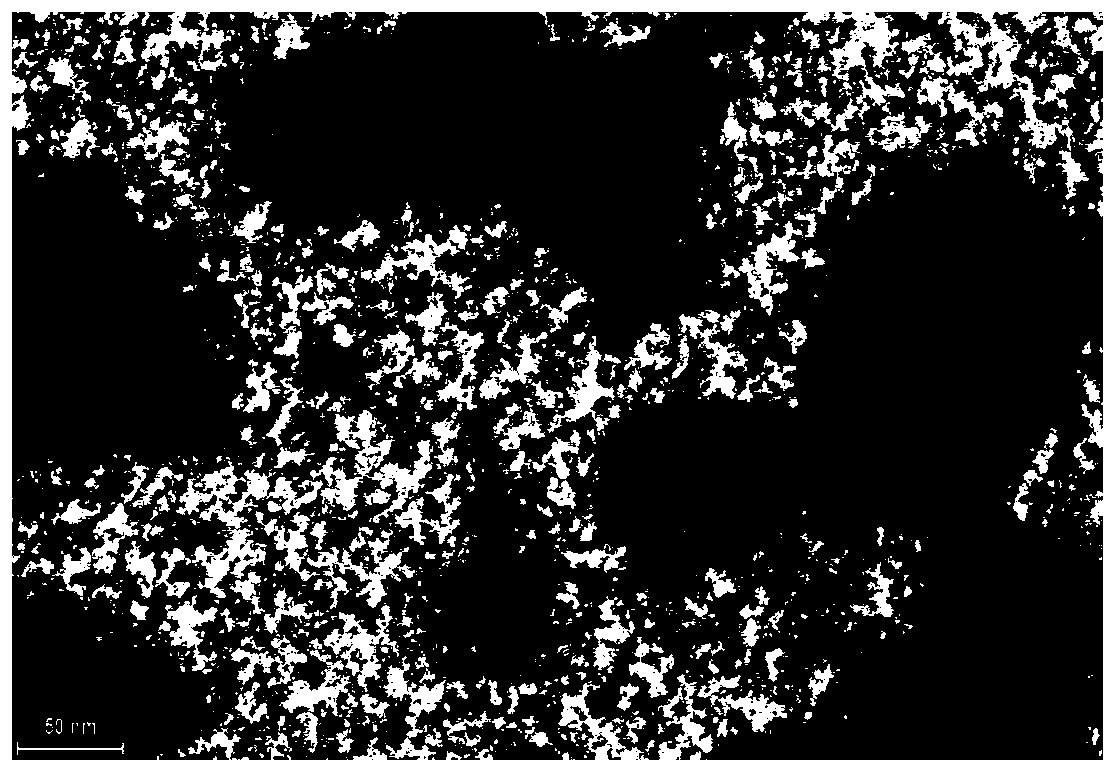

Image

Examples

Embodiment 1

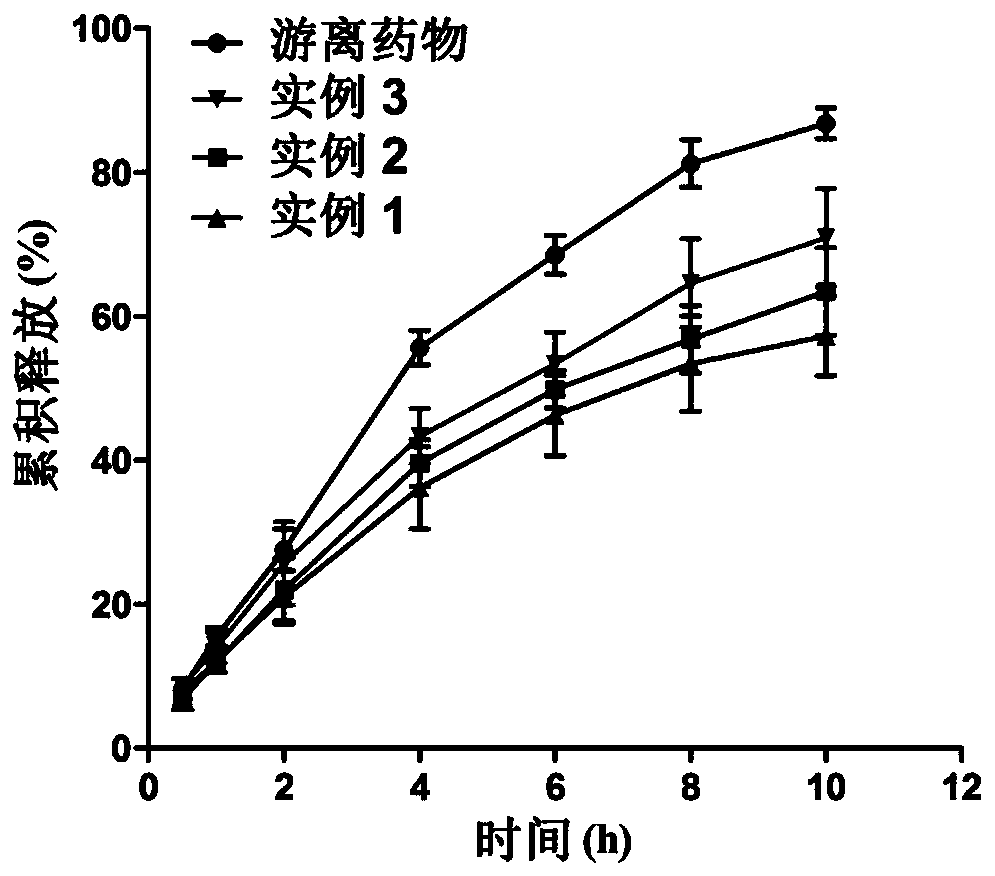

[0032] Example 1 Nano formulation of etomidate of the present invention

[0033] (1) Weigh 100mg lecithin and 10mg etomidate into 2 3ml test tubes, numbered a and b.

[0034] (2) Add 1ml of chloroform to the two test tubes a and b respectively, shake well and shake well until no solid particles remain on the tube wall.

[0035] (3) Inject all the solutions in a and b2 test tubes into a rotary evaporator at 25°C and maintain a constant speed of 60r / min to remove volatile solvents so that liposomes form a lipid dry film on the spherical wall.

[0036] (4) After the film is formed, continue to bubbling in nitrogen for 10 minutes to remove residual volatile organic solvents.

[0037] (5) Add 5 ml of phosphate buffered saline (PBS) with a pH of 7.35, shake and shake well until there are no solid particles remaining on the tube wall. After it is completely dissolved, a phosphate buffer solution with a concentration of 2 mg etomidate per ml is formed, and then the mixed solution is poured int...

Embodiment 2

[0039] Example 2 Nano formulation of etomidate of the present invention

[0040] (1) Weigh 90 mg of lecithin, 10 mg of pluronic P123, and 10 mg of etomidate into three 3 ml test tubes, numbered a, b, and c.

[0041] (2) Add 1ml of chloroform to the 3 test tubes of a, b, and c, shake well, and shake well until there are no solid particles on the tube wall.

[0042] (3) Inject all the solutions in the 3 test tubes of a, b, and c into the rotary evaporator at 25°C and maintain a constant speed of 60r / min to remove volatile solvents so that the liposomes form a lipid dry film on the spherical wall.

[0043] (4) After the film is formed, continue to bubbling in nitrogen for 10 minutes to remove residual volatile organic solvents.

[0044] (5) Add 5 ml of pH 7.35 phosphate buffered saline (PBS), shake and shake well until there are no solid particles remaining on the tube wall. When completely dissolved, a phosphate buffer solution with a concentration of 2 mg etomidate per ml is formed, and...

Embodiment 3

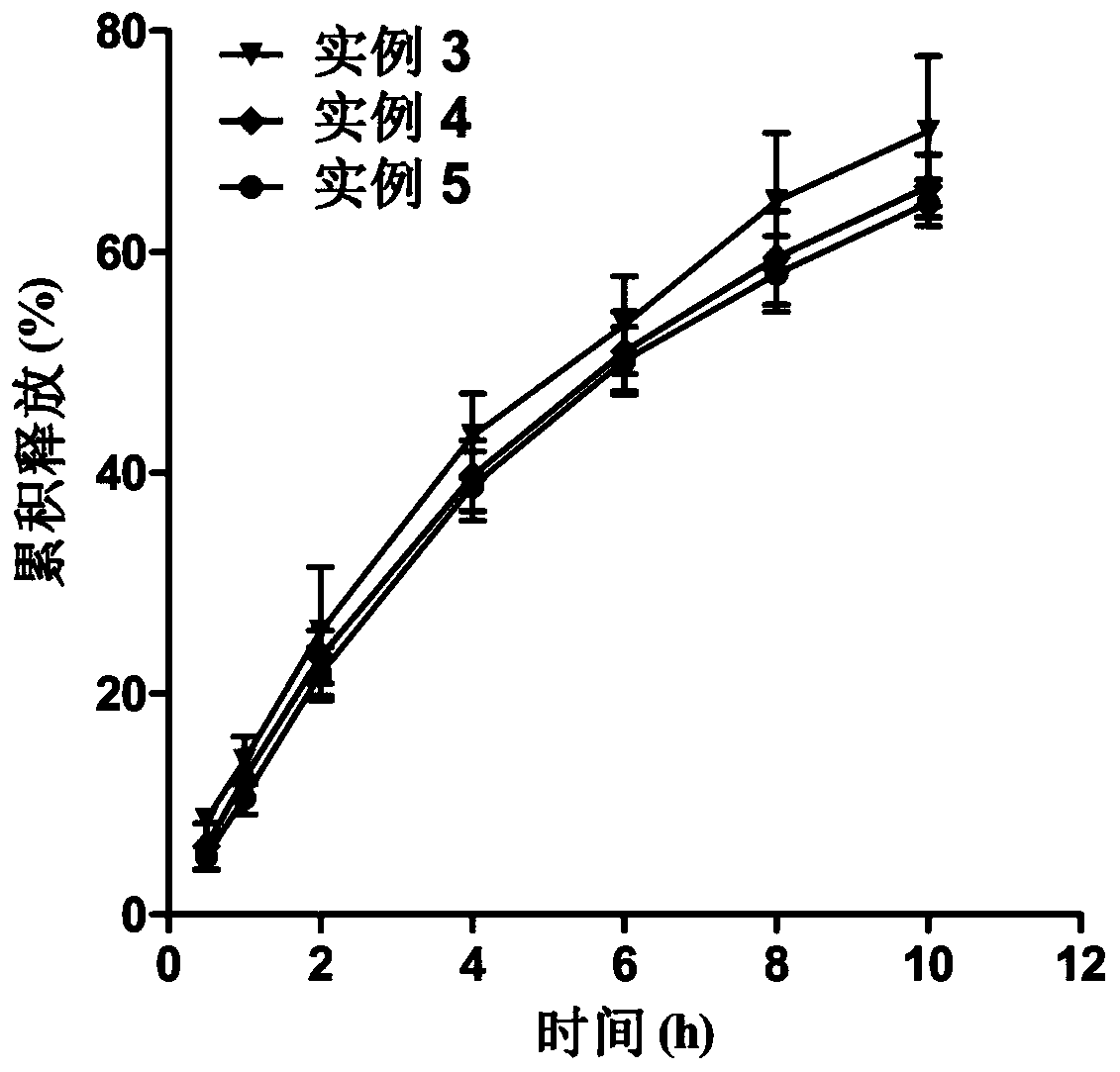

[0046] Example 3 Nano formulation of etomidate of the present invention

[0047] (1) Weigh 80mg lecithin, 20mg pluronic P123, and 10mg etomidate into 3 3ml test tubes, numbered a, b, c

[0048] (2) Add 1ml of chloroform to the 3 test tubes of a, b, and c, shake well, and shake well until there are no solid particles on the tube wall.

[0049] (3) Inject all the solutions in the 3 test tubes of a, b, and c into the rotary evaporator at 25°C and maintain a constant speed of 60r / min to remove volatile solvents so that the liposomes form a lipid dry film on the spherical wall.

[0050] (4) After the film is formed, continue to bubbling in nitrogen for 10 minutes to remove residual volatile organic solvents.

[0051] (5) Add 5 ml of phosphate buffered saline (PBS) with a pH of 7.35, shake and shake well until there are no solid particles remaining on the tube wall. When completely dissolved, a phosphate buffer solution with a concentration of 2 mg etomidate per ml is formed, and then the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com