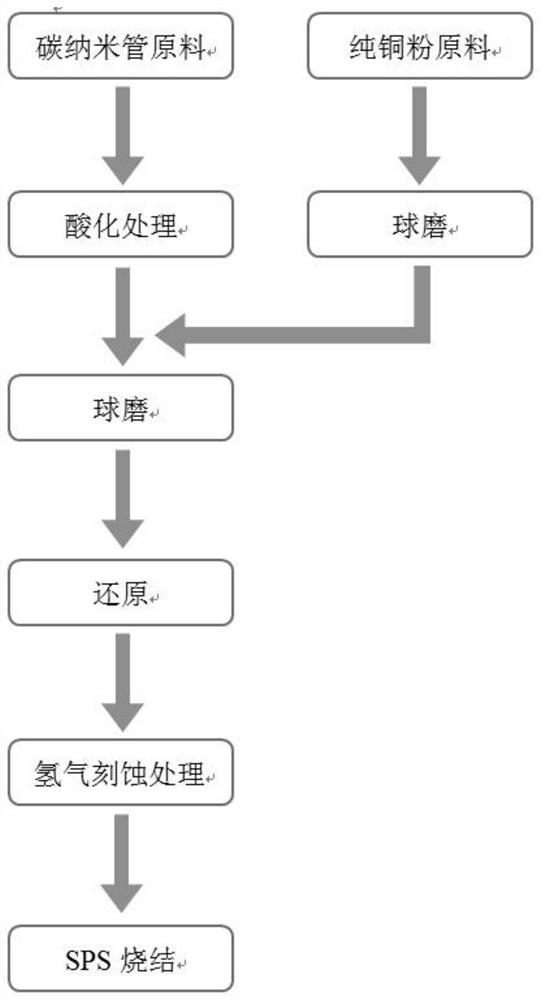

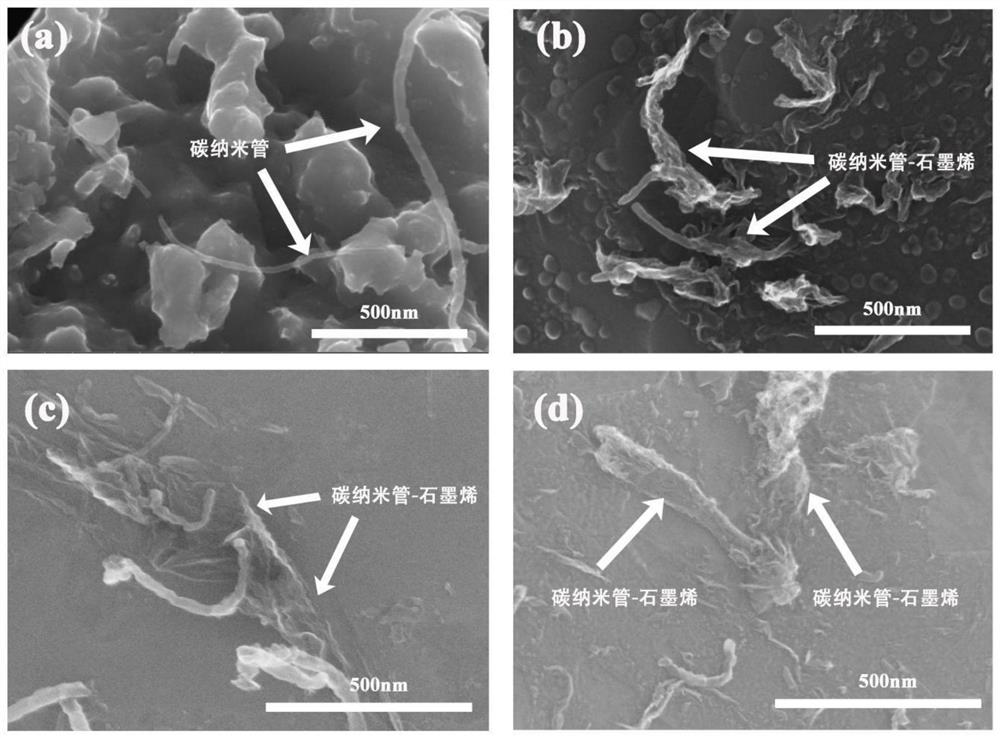

A preparation method of hydrogen-etched carbon nanotube-reinforced copper-based composite material

A technology of copper-based composite materials and carbon nanotubes, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of increased effective contact area and poor plasticity, and achieve improved wettability, improved tensile plasticity, and improved dispersion The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a hydrogen-etched carbon nanotube reinforced copper-based composite material, specifically comprising the following steps:

[0023] (1) Acidification treatment of carbon nanotubes: place 1 g of single-walled carbon nanotubes with a diameter of 50 nm in an acid solution for ultrasonic dispersion treatment for 120 minutes, heat to a temperature of 70 ° C and treat at a constant temperature for 8 hours, and obtain after filtration, washing and drying The carbon nanotubes are pretreated, wherein the acid solution is a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, and the volume ratio of the concentrated sulfuric acid and concentrated nitric acid is 3:1.

[0024] (2) Ball milling treatment of pure copper powder: 35g of pure copper powder (particle size: 2μm) and a certain number of balls are placed in a ball mill tank, a small amount of ethanol is added as a process control agent, the ball-to-material ratio is 10:1, and...

Embodiment 2

[0029] A method for preparing a hydrogen-etched carbon nanotube reinforced copper-based composite material, specifically comprising the following steps:

[0030] (1) Acidification treatment of carbon nanotubes: place 1 g of double-walled carbon nanotubes with a diameter of 60 nm in an acid solution for ultrasonic dispersion treatment for 70 minutes, heat to a temperature of 50 ° C and treat at a constant temperature for 15 hours, and obtain after filtration, washing and drying The carbon nanotubes are pretreated, wherein the acid solution is a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, and the volume ratio of the concentrated sulfuric acid and concentrated nitric acid is 3:1.

[0031] (2) Ball milling treatment of pure copper powder: 35g of pure copper powder (particle size 4μm) and a certain number of balls are placed in a ball mill tank, a small amount of ethanol is added as a process control agent, the ball-to-material ratio is 5:1, and t...

Embodiment 3

[0036] A method for preparing a hydrogen-etched carbon nanotube reinforced copper-based composite material, specifically comprising the following steps:

[0037](1) Acidification treatment of carbon nanotubes: place 1 g of multi-walled carbon nanotubes with a diameter of 80 nm in an acid solution for ultrasonic dispersion treatment for 20 minutes, heat to a temperature of 80 ° C and treat at a constant temperature for 6 hours, and obtain after filtration, washing and drying The carbon nanotubes are pretreated, wherein the acid solution is a mixed acid solution of concentrated sulfuric acid and concentrated nitric acid, and the volume ratio of the concentrated sulfuric acid and concentrated nitric acid is 4:1.

[0038] (2) Ball milling of pure copper powder: put 35g of pure copper powder (particle size 4μm) together with a certain number of balls in a ball mill tank, add a small amount of ethanol as a process control agent, the ball-to-material ratio is 6:1, and the ball mill T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com