Method for treating surface of aluminum article

A treatment method and surface treatment technology, applied in the direction of chemical instruments and methods, layered products, superimposed layer plating, etc., can solve the problem of difficult waste liquid treatment, and achieve the effect of firm joint and effective anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

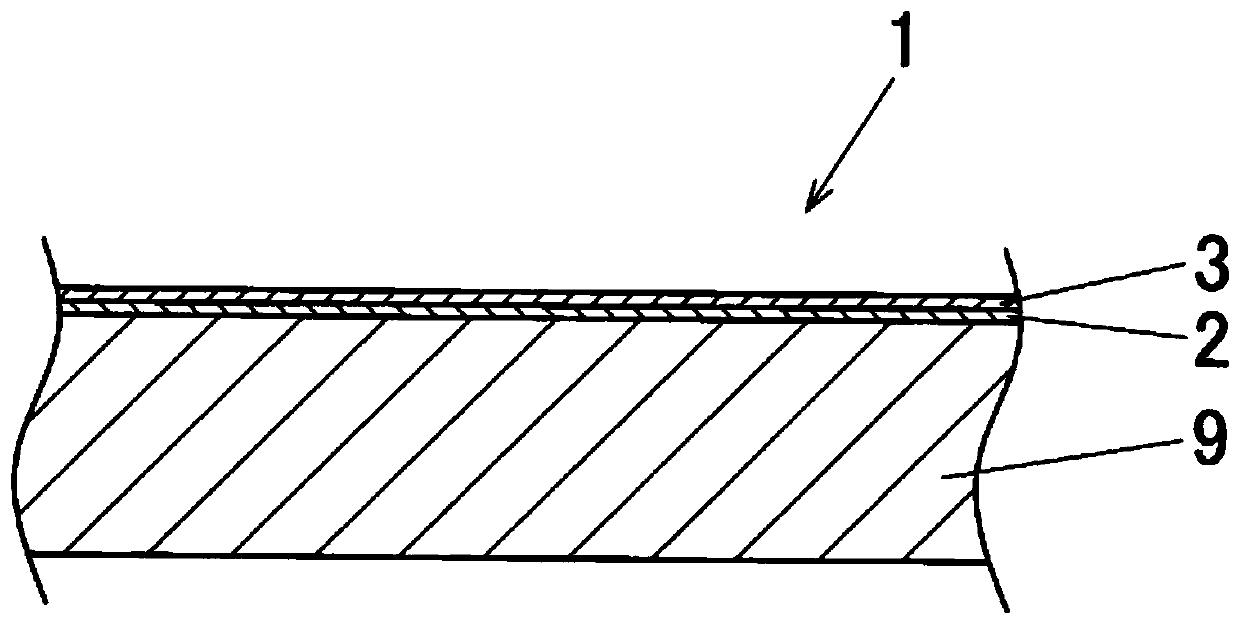

Image

Examples

Embodiment

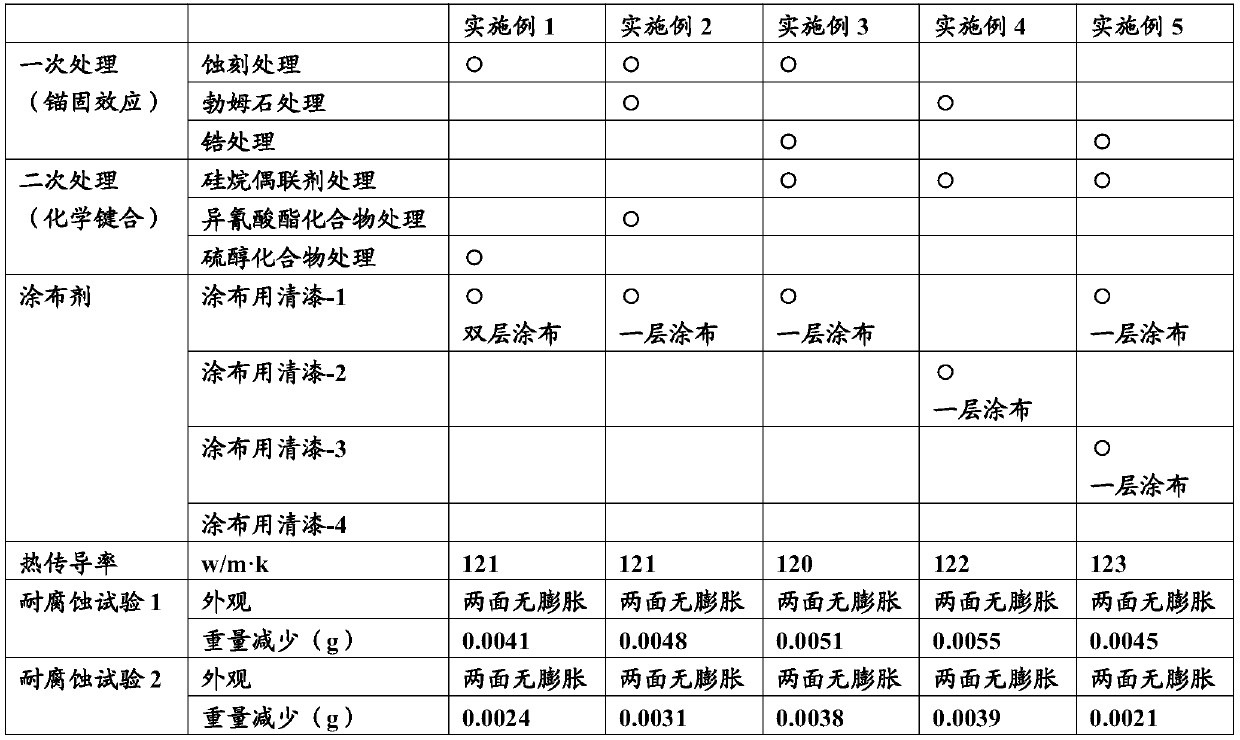

[0118] Hereinafter, although an Example and a comparative example demonstrate this invention in detail, these do not limit this invention.

Synthetic example 1

[0119] (Synthesis Example 1) Synthesis of Allylated Phenolic Resin

[0120] In a flask equipped with a stirrer and a reflux tube, 720 g of potassium carbonate, 12 g of triphenylphosphine, 1100 g of water, 4 g of 5% Pd / C, and 104 g (1.0 equivalent) of novolac manufactured by Aika SDK Fenol Co. Resin "BRG556", 569 g (1.2 equivalents) of allyl acetate, and continued reaction at 90 degreeC for 8 hours.

[0121] Next, the reaction liquid was cooled to 40° C., 400 g of toluene and 400 g of water were added and stirred, and the reaction liquid was filtered, liquid-separated, and the toluene layer was taken out, and toluene and allyl acetate were distilled off under reduced pressure. Then, 400 g of toluene was further added to the residue, dissolved in toluene, the resulting toluene liquid was washed with water three times, and the toluene was distilled off under reduced pressure to obtain BRG556 allyl ether in a yield of 95%.

Embodiment 1

[0124]

[0125] 24 parts by weight of (A) Epicoat 1001 manufactured by Mitsubishi Chemical Corporation as an epoxy resin and 16 parts by weight of (B) a phenolic resin "BRL-240" from Aika SDK Fenol Co., Ltd. as a phenolic resin were dissolved in 50 parts by weight of In a solvent consisting of MEK and 60 parts by weight of water, 0.4 parts by weight of 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) was added to the resulting solution to prepare a coating varnish -1.

[0126]

[0127] (one time processing)

[0128] Prepare an aluminum plate of 50 mm x 90 mm (thickness: 2.0 mm) (brazed with surface: No. 3000, back: No. 4000), etch it with sodium hydroxide (immerse in 5% sodium hydroxide aqueous solution for 1.5 minutes Then neutralize with 5% nitric acid, wash with water and dry).

[0129] (secondary processing)

[0130] Next, the aluminum plate subjected to the primary treatment was immersed at 30° C. in 100 g of toluene in which 5.44 g of pentaerythritol tetrakis (3-mer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com