Copper-oxygen-based high-temperature superconducting single-photon detector and preparation method thereof

A single-photon detector and high-temperature superconducting technology, applied in the field of light detection, can solve problems such as low light absorption efficiency, affect the application of copper-oxygen high-temperature superconducting materials, and difficult precise processing, so as to increase light absorption and improve light absorption The effect of low efficiency, usage and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

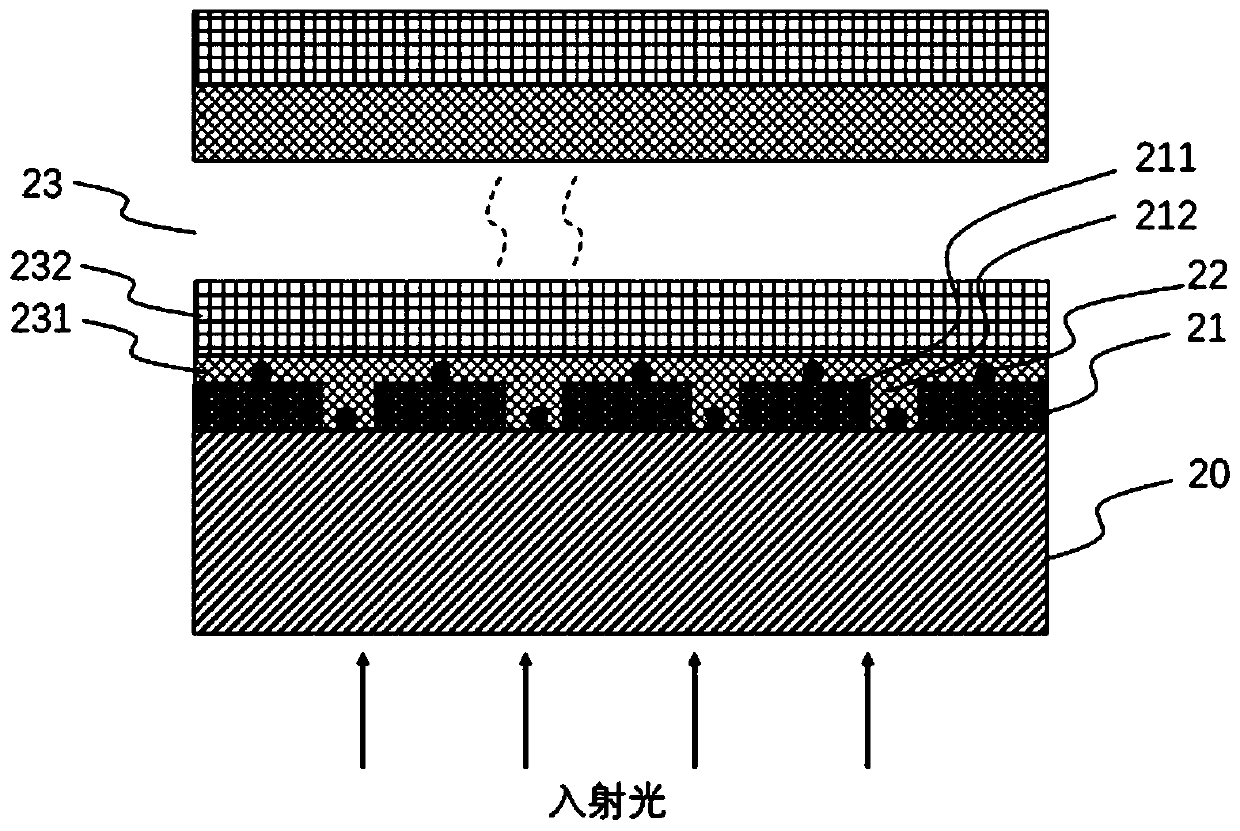

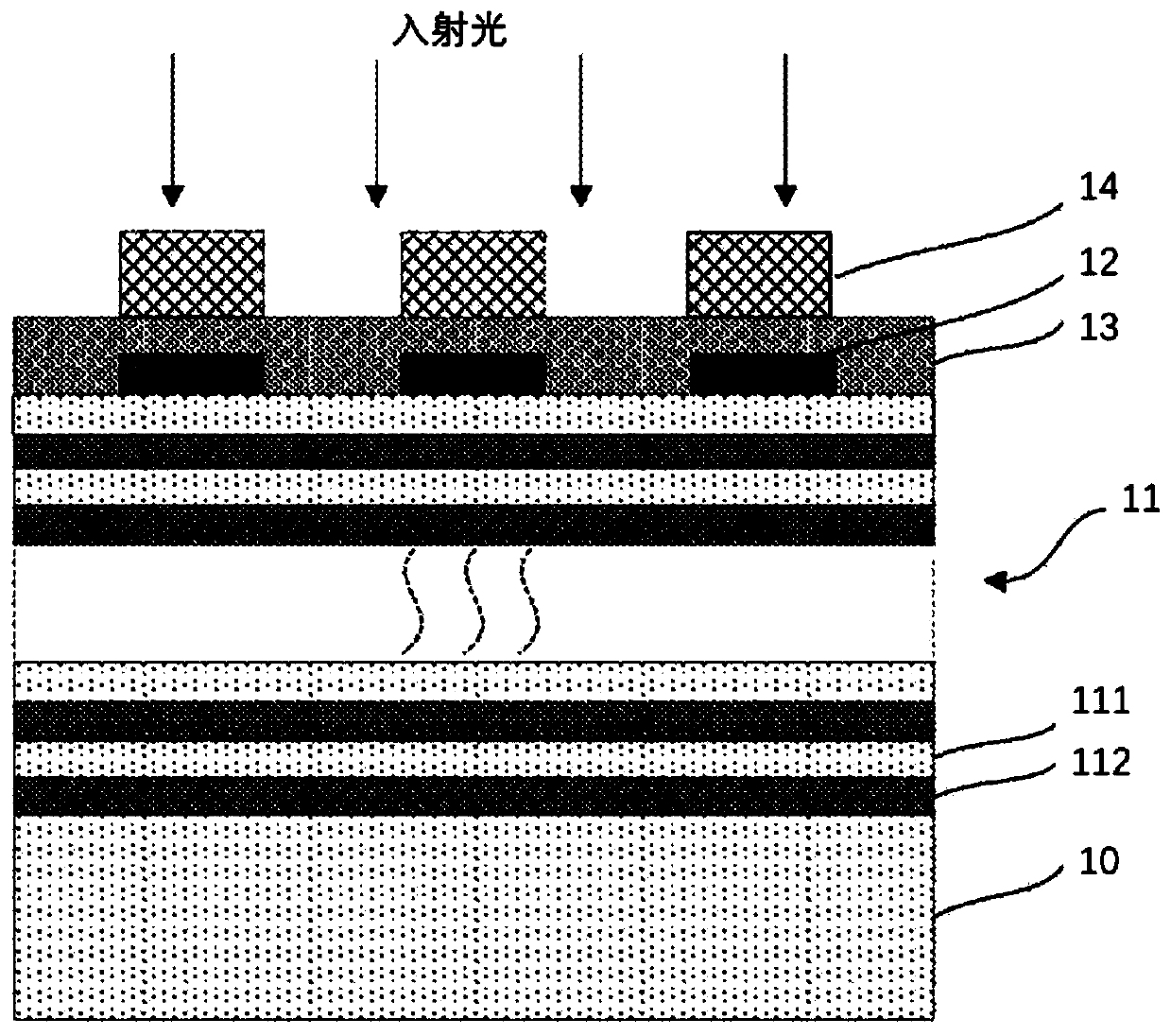

[0046] A copper-oxide high-temperature superconducting single-photon detector, such as figure 1 As shown, it includes a substrate 20, a copper oxide high temperature superconducting microwire 211 and a dielectric thin film mirror 23 arranged in sequence from bottom to top. A nanohole array is arranged in the copper oxide high temperature superconducting microwire 211, and the copper oxide high temperature superconducting microwire 211 is provided with a nanohole array. Metal nanoparticles 22 are disposed on the high temperature superconducting microwire 211 .

[0047] In the present invention, the copper-oxygen high-temperature superconducting micro-wire 211 can enable the superconducting single-photon detector to work at a temperature of 77K, which facilitates the use of the superconducting single-photon detector. Arranging nanohole arrays on the copper-oxygen high-temperature superconducting microwires 211 can make the microwires into a submicron wire (one hundred or tens of...

Embodiment 2

[0066] A copper-oxygen high-temperature superconducting single-photon detector and a preparation method thereof provided according to Embodiment 1, the difference is that:

[0067] The substrate 20 is a strontium titanate substrate with a thickness of 500 μm. The material of the high temperature superconducting microwire is Bi 2 Sr 2 Ca 2 Cu 3 o 10 (BSCCO).

[0068] The shape of the copper-oxygen high-temperature superconducting micro-wire 211 is a spiral curve, the width of the high-temperature superconducting micro-wire is 5 μm, and the thickness is 40 nm; Figure 8 As shown, the shape of the nanoholes 212 is an ellipse, the long axis is 130 nm, and the short axis is 70 nm. The array formed by the nanoholes 212 is arranged periodically in a two-dimensional hexagonal structure with a period length of 230 nm.

[0069] Metal nanoparticles 22 are silver nanospheres with a diameter of 50 nm.

[0070] The dielectric film mirror 23 includes alternately stacked low refractive...

Embodiment 3

[0072] A copper-oxygen high-temperature superconducting single-photon detector and a preparation method thereof provided according to Embodiment 1, the difference is that:

[0073] The substrate 20 is a lanthanum aluminate substrate, and the material of the copper-oxygen high-temperature superconducting micro-wire 211 is HgBa 2 Ca 2 Cu 3 o 8 (HBCCO).

[0074] The shape of the metal nanoparticles 22 is a gold nanorod, the length of the gold nanorod is 50 nm, and the diameter of the end surface of the gold nanorod is 50 nm.

[0075] The dielectric film mirror 23 includes alternately stacked low refractive index dielectric layers 231SiO 2 layer and the high-refractive-index dielectric layer 232Si layer, and the layer in contact with the copper-oxygen high-temperature superconducting microwire 21 containing the nanohole array is the low-refractive-index dielectric layer 231SiO 2 layer. The thickness of each medium layer is 1 / 4 of the incident wavelength in this medium, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com