A kind of anti-ash absorption and good appearance polypropylene composite and preparation method thereof

A polypropylene and composite technology, applied in the field of polypropylene materials, to avoid the phenomenon of ash absorption, accelerate precipitation, and weaken the imprint of the suction cup of the manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

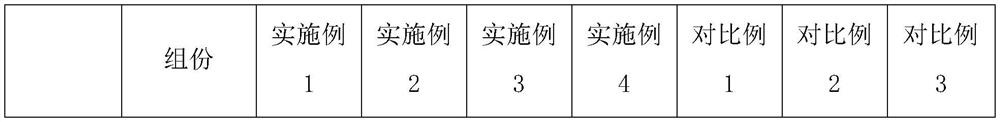

[0055] A kind of anti-ash absorption and good appearance polypropylene composite, its raw material formula is shown in Table 1, and the preparation method is:

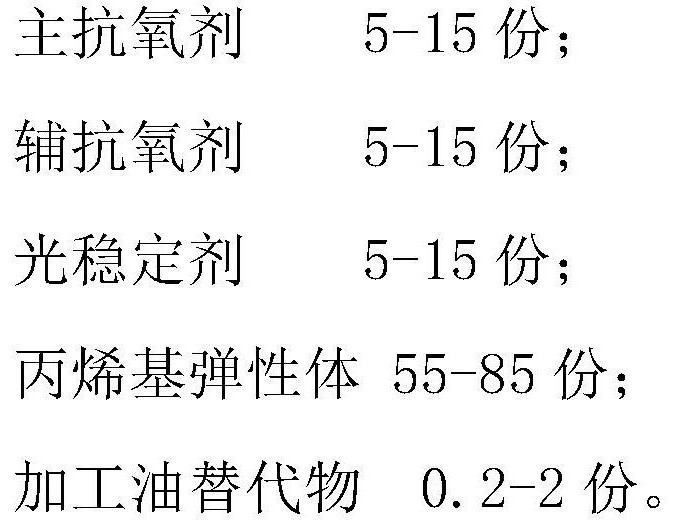

[0056] 1) Add main antioxidant, auxiliary antioxidant, light stabilizer, processing oil substitute and propylene-based elastomer into an internal mixer or other meshing equipment to mix evenly, and then granulate to obtain additive masterbatch;

[0057] 2) Add polypropylene and polyethylene into the mixer and mix evenly, then add the processing oil substitute to continue mixing, then add dust-proofing agent and additive masterbatch and mix them evenly, then add them to the main feeding port of the twin-screw extruder. , carry out melt blending, vacuum extrusion granulation, namely obtain the described anti-ash absorption and good appearance polypropylene composite material;

[0058] The processing temperature of the twin-screw extruder is 180°C, and the vacuum degree is -0.1MPa;

[0059] The polypropylene used is copo...

Embodiment 2

[0061] A kind of anti-ash absorption and good appearance polypropylene composite, its raw material formula is shown in Table 1, and the preparation method is:

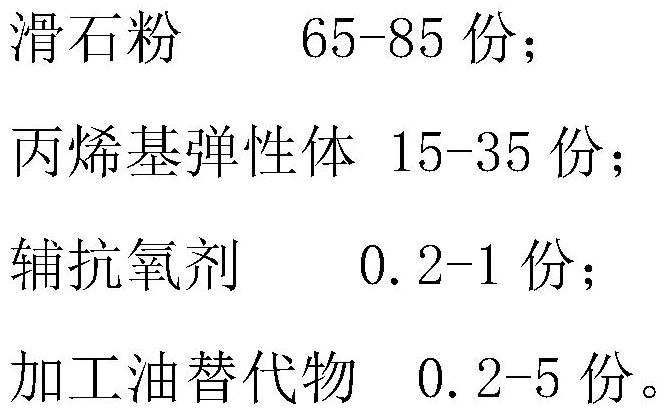

[0062] 1) Add talc, propylene-based elastomer, auxiliary antioxidant, and processing oil substitute to an internal mixer or other meshing equipment to mix evenly, and then granulate to obtain talc masterbatch;

[0063] 2) Add main antioxidant, auxiliary antioxidant, light stabilizer, processing oil substitute and propylene-based elastomer into an internal mixer or other meshing equipment to mix evenly, and then granulate to obtain additive masterbatch;

[0064] 3) Add polypropylene, polyethylene, elastomer and talc masterbatch into the mixer and mix evenly, then add the processing oil substitute to continue mixing, then add dustproofing agent and additive masterbatch and mix them evenly before adding to the twin-screw extruder. At the main feeding port of the machine, melt blending, vacuum extrusion and granulation are...

Embodiment 3

[0068] A kind of anti-ash absorption and good appearance polypropylene composite, its raw material formula is shown in Table 1, and the preparation method is:

[0069] 1) Add talc, propylene-based elastomer, auxiliary antioxidant, and processing oil substitute to an internal mixer or other meshing equipment to mix evenly, and then granulate to obtain talc masterbatch;

[0070] 2) Add main antioxidant, auxiliary antioxidant, light stabilizer, processing oil substitute and propylene-based elastomer into an internal mixer or other meshing equipment to mix evenly, and then granulate to obtain additive masterbatch;

[0071] 3) Add polypropylene, polyethylene, elastomer and talc masterbatch into the mixer and mix evenly, then add the processing oil substitute to continue mixing, then add dustproofing agent and additive masterbatch and mix them evenly before adding to the twin-screw extruder. At the main feeding port of the machine, melt blending, vacuum extrusion and granulation are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com