N-type crystalline silicon PERT double-sided battery with new structure and preparation method of n-type crystalline silicon PERT double-sided battery

A double-sided battery and new structure technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of insufficient passivation, high cost, and low efficiency of the carrier metal electrode area, and achieve superior compactness and open circuit Effect of voltage and conversion efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

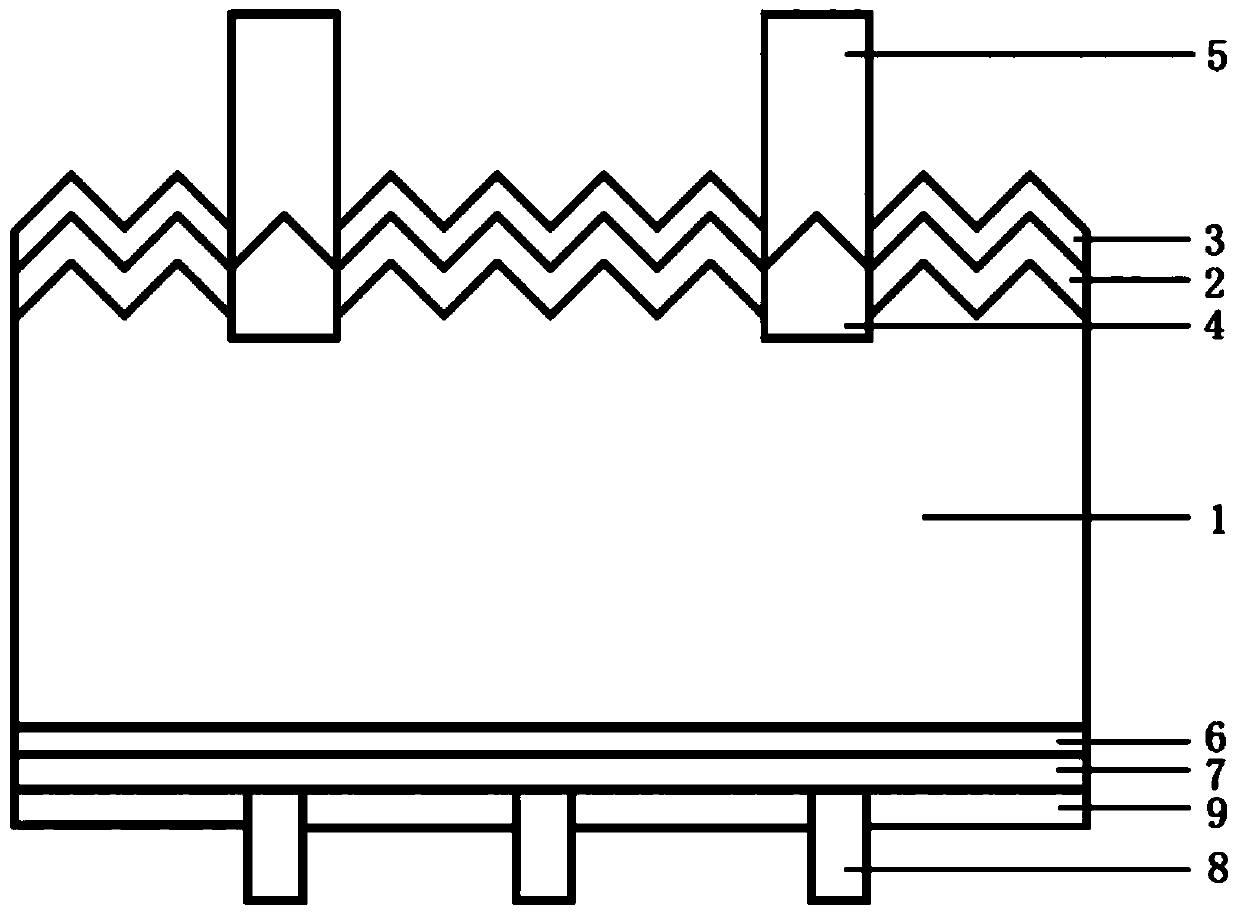

[0037] Embodiment 1: The preparation method of the new structure N-type crystalline silicon PERT bifacial battery of the present invention is as follows:

[0038] Step 1, prepare an n-type Cz single crystal silicon wafer with an industrial-grade crystal orientation of (100) as an n-type crystalline silicon substrate, and use sodium hydroxide solution to remove the damaged layer formed on the surface of the n-type crystalline silicon substrate due to wire cutting ;

[0039] Step 2, texture the n-type crystalline silicon substrate obtained in step 1 with an alkaline solution, and then perform standard RCA cleaning to obtain a pretreated silicon wafer;

[0040] Step 3, put the silicon wafers obtained in step 2 back to back into a traditional high-temperature diffusion furnace for BBr 3 Diffusion, forming p on the positive surface + emission level layer;

[0041] Step 4, using a nanosecond pulsed laser with a wavelength of 532 nm and a pulse energy between 80 μJ and 300 μJ to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com