Control method for eliminating weld crack of high temperature titanium alloy plate

A technology for high-temperature titanium alloy and weld cracks, which is applied in the field of elimination and control of high-temperature titanium alloy plate weld cracks, can solve problems such as cracks, and achieve the effect of improving stability and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

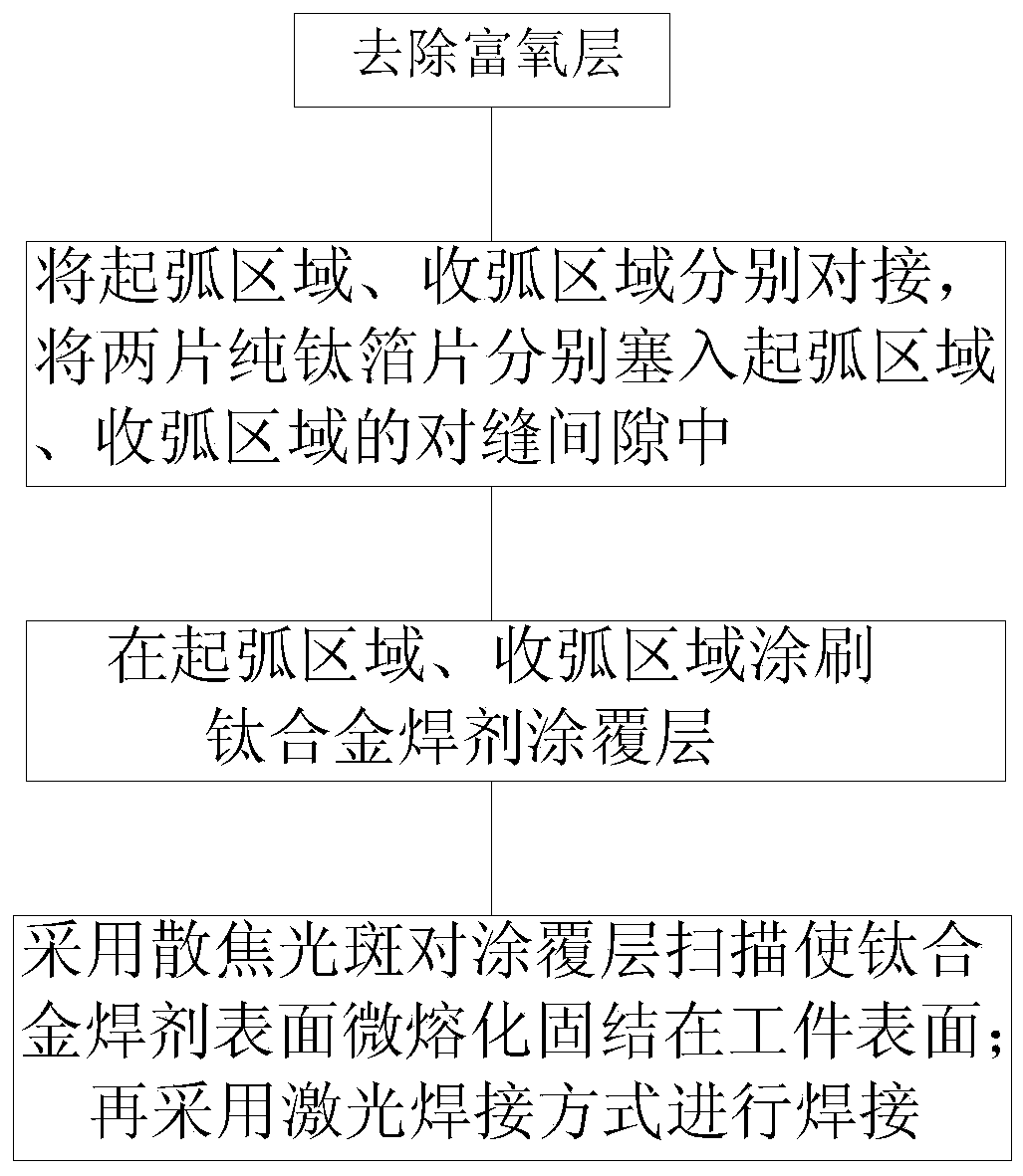

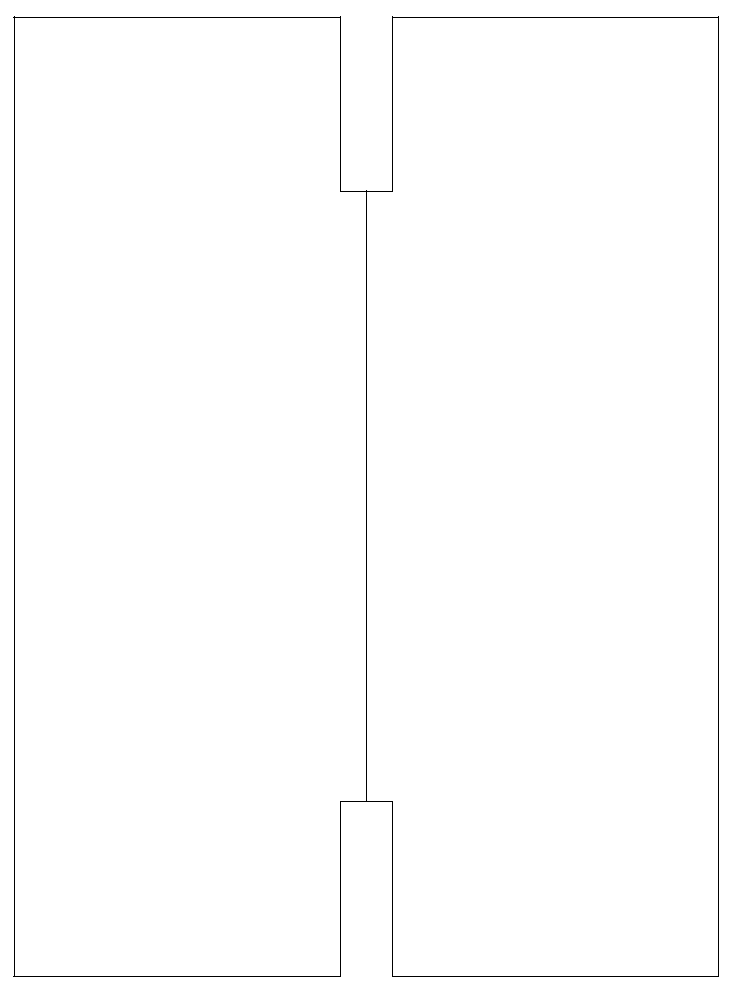

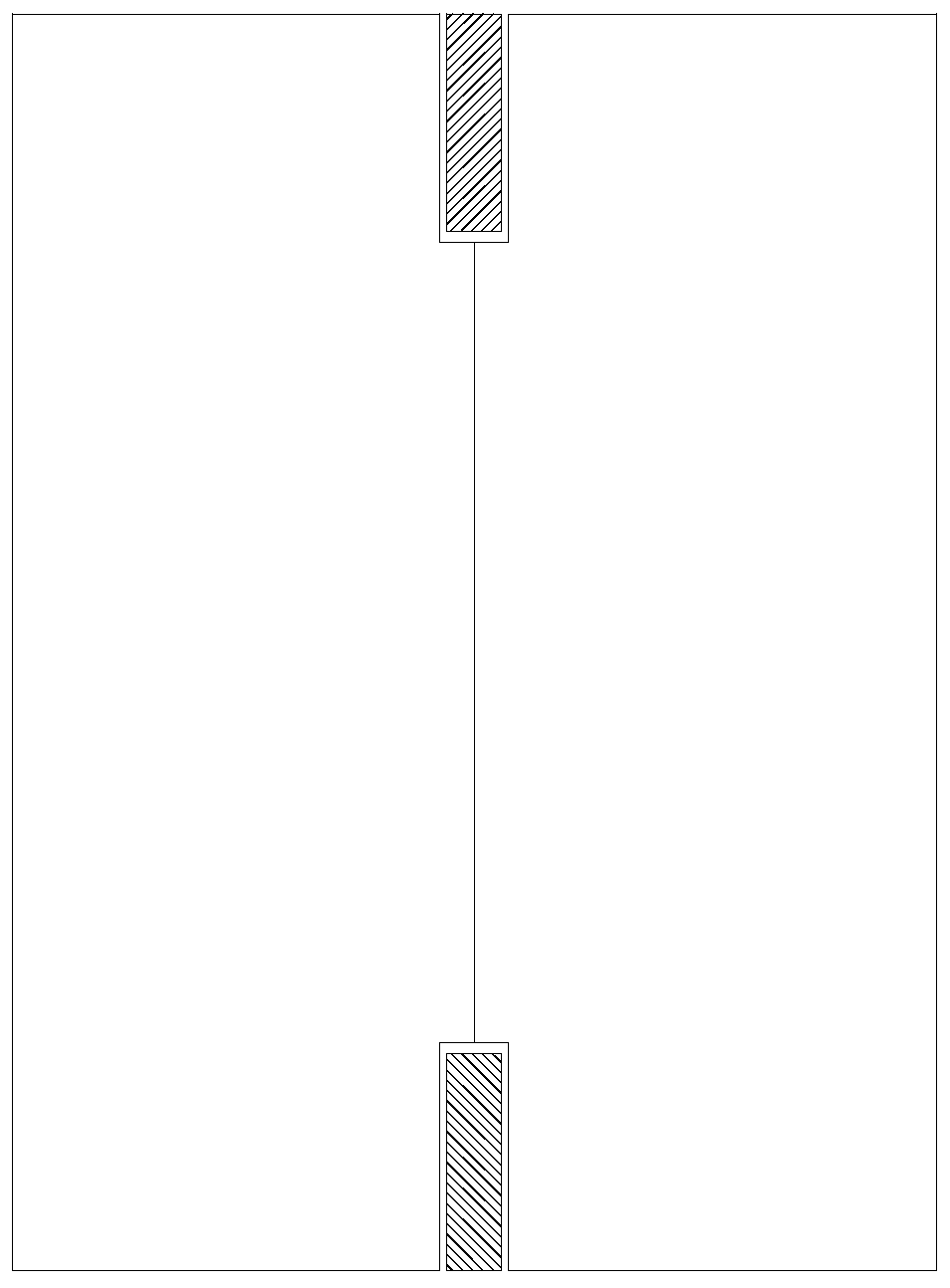

Method used

Image

Examples

preparation example Construction

[0049] Further, the preparation method of the titanium alloy flux described in the method for eliminating and controlling weld seam cracks of high-temperature titanium alloy plates shown in the embodiments of the present invention includes: mixing 300-500 mesh pure titanium powder, 300-500 mesh BaCl 2 Powder, 300-500 mesh NaF 2 The powder is mixed according to the mass ratio of 20:1:1, and the obtained mixture and alcohol are mixed evenly according to the ratio of 1:3, and the mixture settled at the bottom is used as the titanium alloy flux. In the embodiment of the present invention, the above-mentioned titanium alloy flux is painted on the arc starting area and the arc ending area. On the one hand, the titanium alloy flux is filled with pure titanium powder, and the gap between the titanium foil and the high-temperature titanium alloy plate is avoided to avoid Weld collapse or undercut caused by lack of material; on the other hand, BaCl in titanium alloy flux 2 Powder, NaF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com