Urinary catheter

A urinary catheter and hydrophilic technology, applied in catheters, coatings, pharmaceutical formulations, etc., can solve problems such as environmental pollution, cumbersome steps, poor uniformity and firmness, etc., to avoid environmental pollution, reduce the use of organic solvents, The effect of high lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

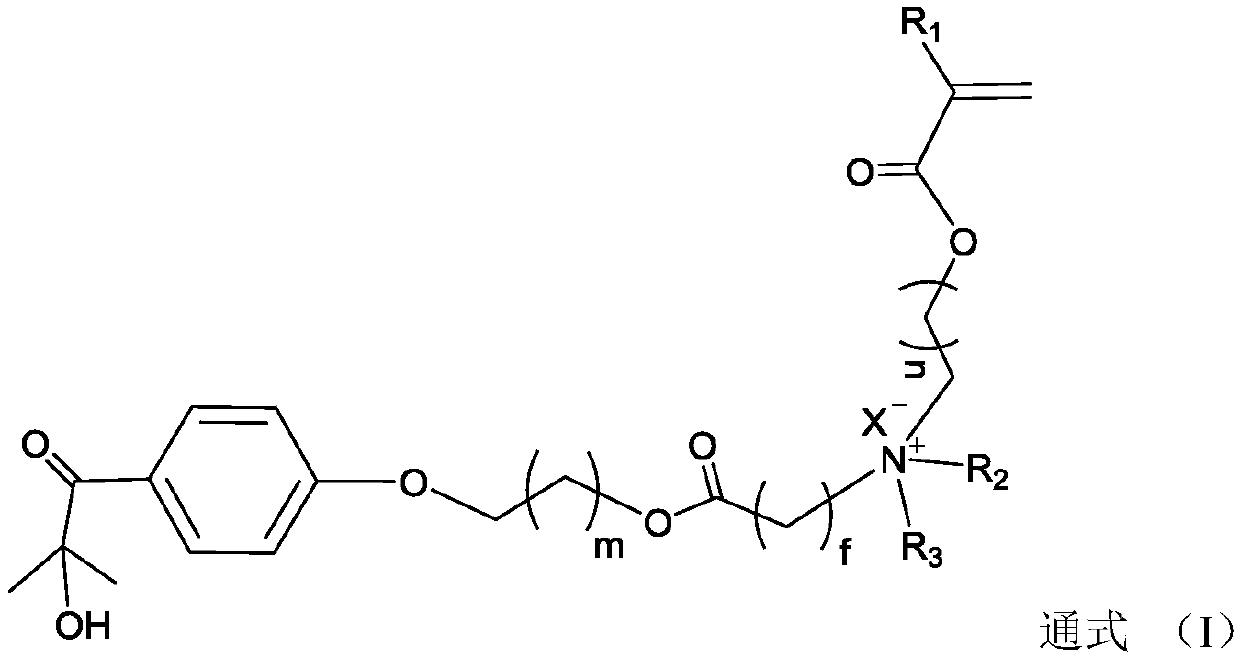

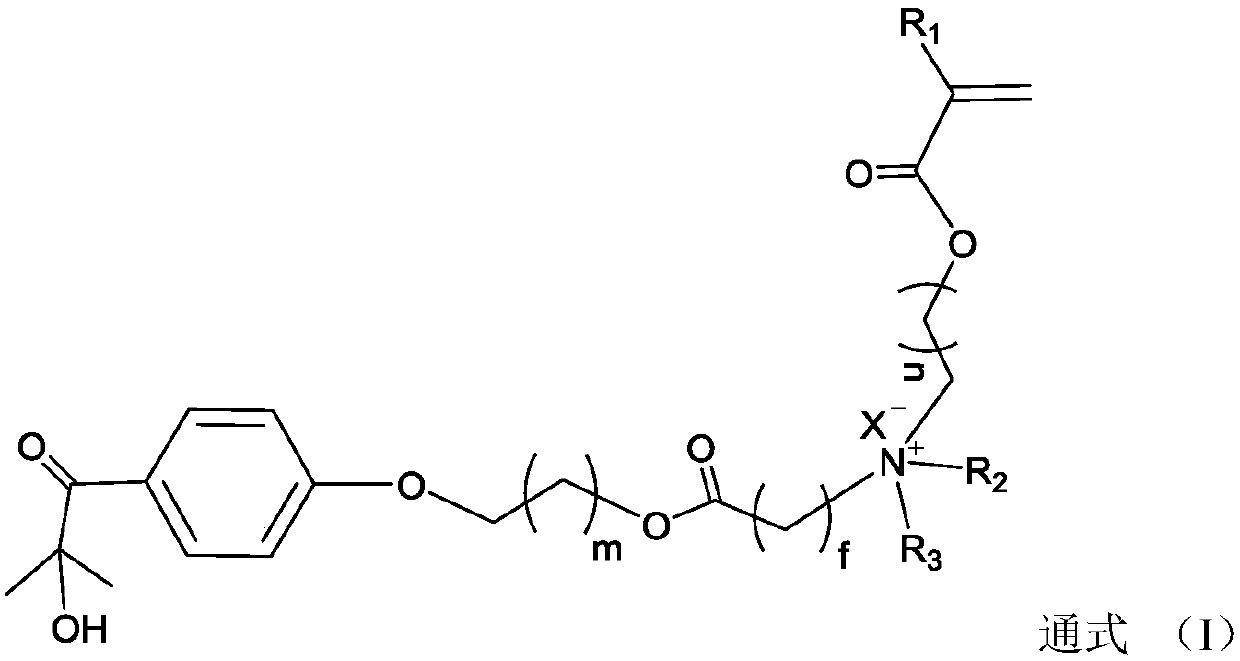

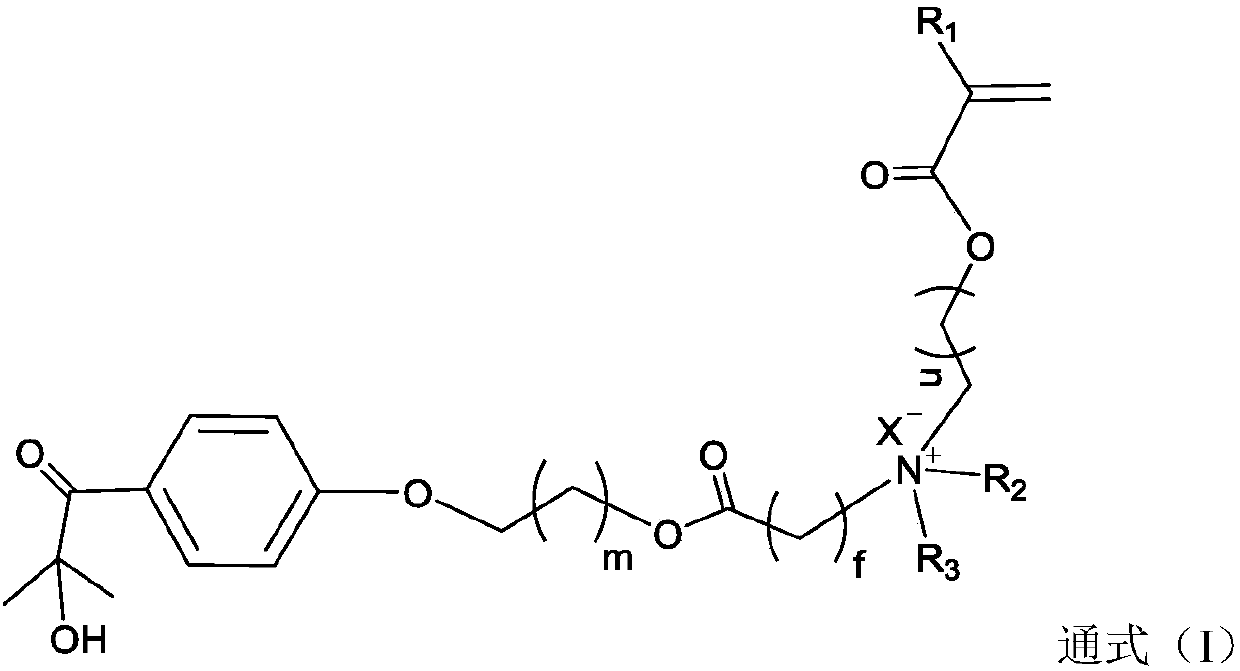

[0093] Step 1: Synthesis of water-soluble polymerizable photosensitive monomer

[0094] Weigh 22.4g (100mmol) 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, 10.6g (105mmol) triethylamine and dissolve in 100mL dichloromethane and place in a 250mL flask and placed in an ice-water bath to fully dissolve. 9.1 mL of bromoacetyl bromide (21.1 g, 105 mmol) in dichloromethane was slowly added dropwise to the flask, and the dropwise addition was completed within 1 h. After reacting for 0.5 h under ice-bath conditions, the reaction was continued for 10 h at room temperature. After the reaction was completed, cool to room temperature and dissolve the crude product in dichloromethane, wash twice with saturated brine, hydrochloric acid (1M) and saturated sodium bicarbonate successively, dry over anhydrous magnesium sulfate, filter and spin dry the solvent, wash with acetic acid Ethyl ester and n-hexane were used as eluents, and after purification by column chromatography, 28.8g of...

Embodiment 2

[0107] Change the material of the urinary catheter used in Step 4 of Example 1, and other steps are the same as in Example 1, and the lubrication performance is evaluated, and the results are shown in Table 1.

[0108] In addition, catheters of different materials were taken directly, the surface was wiped clean with dust-free paper dipped in 75% ethanol, and after drying, they were placed in a clip-type friction tester to test the lubrication performance. The results are shown in Table 1.

[0109] Table 1 Lubrication properties of catheters made of different materials

[0110]

[0111] It can be seen that the urinary catheter with the hydrophilic coating of the present invention can significantly reduce the friction force after 30 cycles, and the lubricating performance is more stable and durable. In addition, the lubricating performance of the polyvinyl chloride catheter is relatively the best, because the coating liquid has the best affinity with the PVC catheter, and th...

Embodiment 3

[0113] Change the reaction time of step 2 and the amount of initiator in Example 1 to obtain photocurable polymers with different molecular weights (the molecular weight in Table 2 is rounded up), and the other steps are the same as in Example 1, and the lubricating properties are evaluated , the results are shown in Table 2.

[0114] Table 2 The effect of photocurable polymer molecular weight on the performance of PVC catheter coating

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com