Method for enhancing low temperature impact toughness of steel plate applied to railway

A low-temperature impact toughness and steel plate technology, applied in the field of steel manufacturing, can solve the problems of deteriorating the welding performance of steel plates, increasing the amount of alloy content added, economic losses, etc. The effect of impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

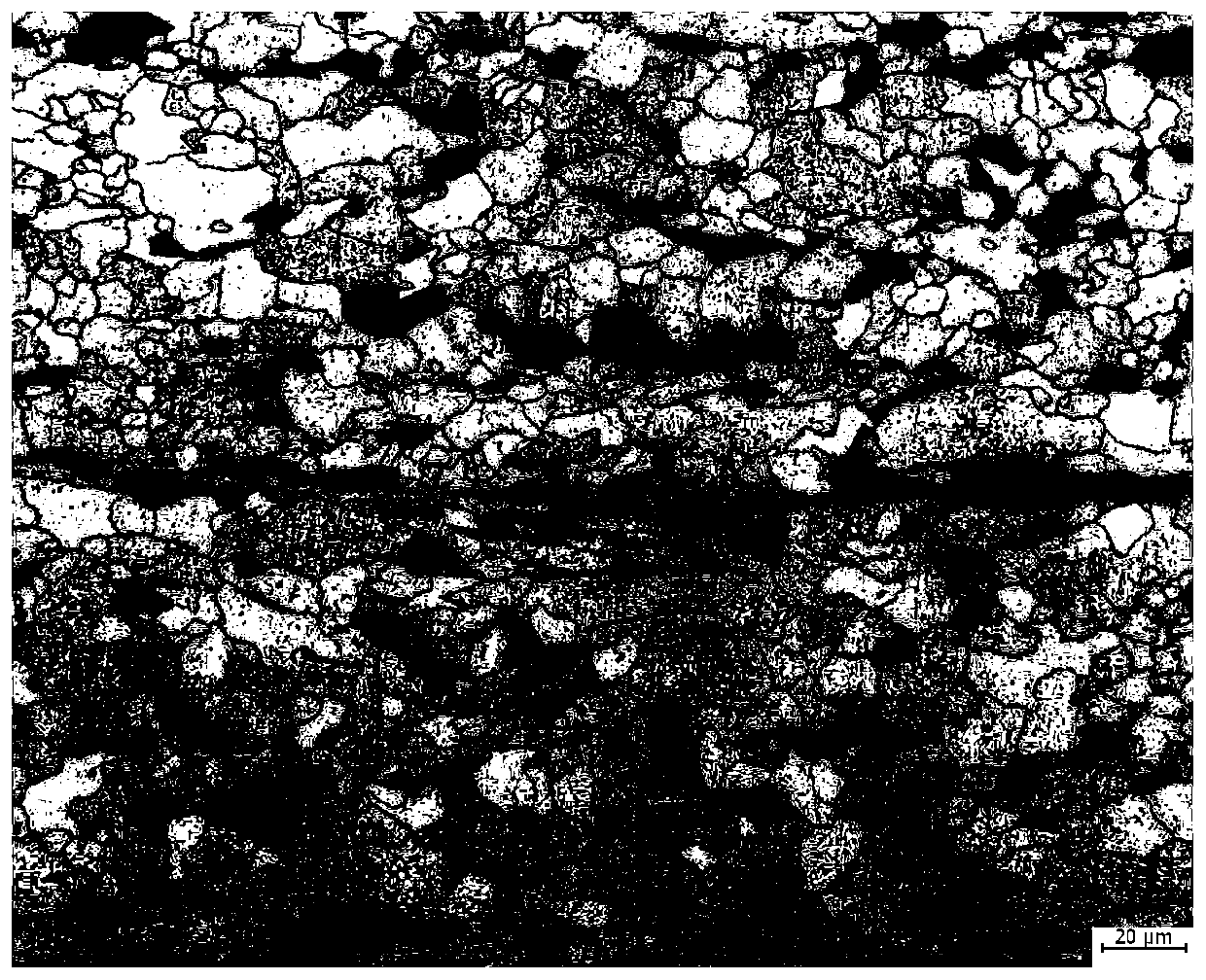

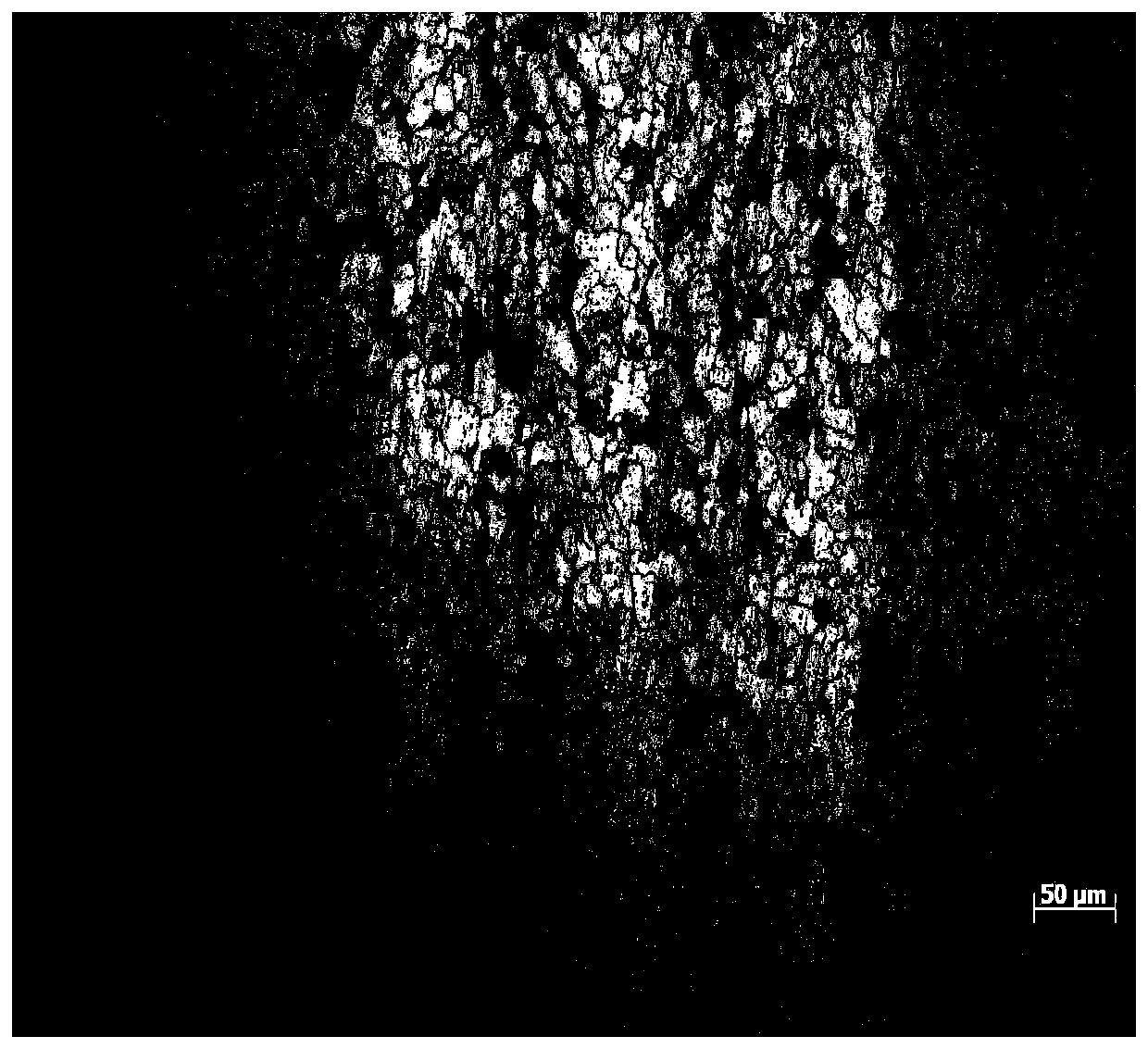

Image

Examples

Embodiment Construction

[0014] Below, the manufacturing method of the present invention will be further described in detail in combination with specific cases. The manufacturing process parameters of each case are shown in Table 1.

[0015] Table 1 process parameters

[0016]

[0017]

[0018] As shown in the table above, embodiment 1-6 is all manufactured by the method of the present invention, comparative example 1-2 does not carry out tempering treatment according to the tempering temperature required by the present invention, comparative example 3 does not carry out tempering furnace temperature according to the requirement of the present invention The uniformity control of Comparative Example 4-5 was not carried out according to the holding time required by the present invention. Comparative Example 6 added a large amount of alloy elements to cause the carbon equivalent to exceed the limit of the present invention, and did not perform rapid medium temperature tempering treatment.

[0019]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com