White polyimide composite film and preparation method thereof

A polyimide and composite film technology, applied in the field of material science, can solve the problems of poor temperature resistance of the coating layer, low service temperature, and high addition of inorganic fillers, and achieve easy popularization and application, improved mechanical properties, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

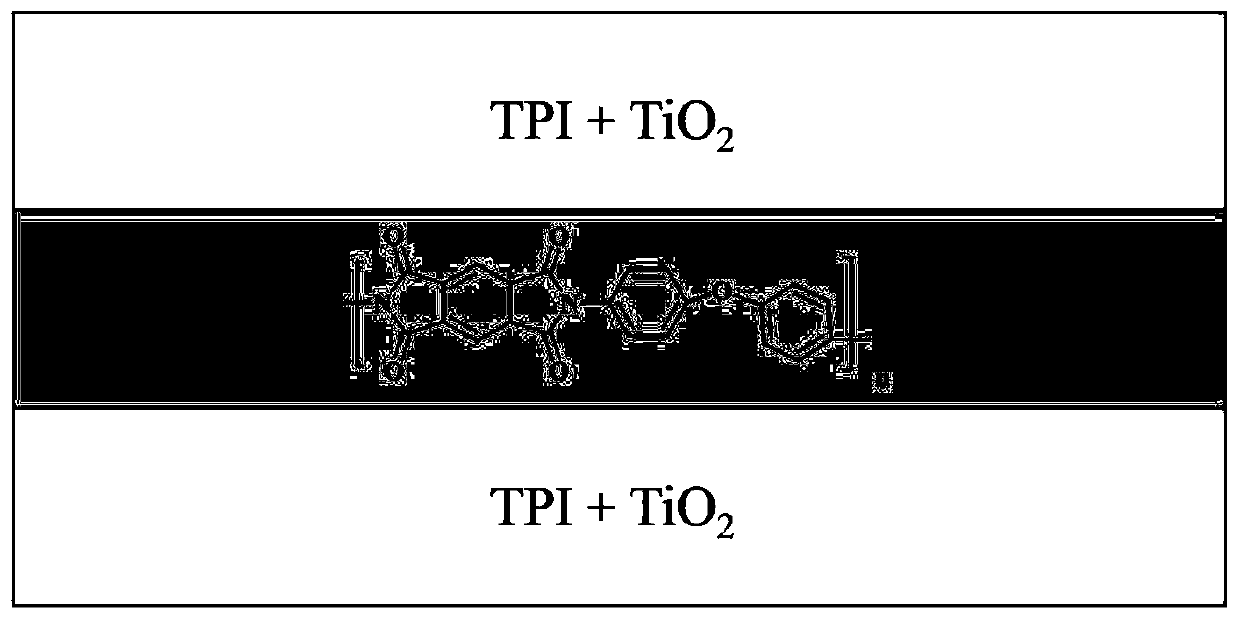

[0037] The schematic diagram of the white polyimide composite film PI111 in the present embodiment 1 is as follows figure 1 Shown:

[0038] The preparation method of above-mentioned white polyimide composite film PI111 is as follows:

[0039] (1) Preparation of glue solution PI-1.1

[0040] Weigh TiO 2 3.0g into a round bottom flask, add solvent N,N-dimethylacetamide (DMAc) 80.0g, ultrasonically stir for 1h, then protect with argon, and add 15.0g of soluble PI, continue stirring at room temperature for 5h , to obtain transparent, homogeneous and viscous white transparent polyimide glue PI-1.1.

[0041] (2) Preparation of glue solution PI-2.1

[0042] Weigh 6.0072g (0.03mol) of 4,4'-diaminodiphenyl ether (ODA) and 50g of N,N-dimethylacetamide (DMAc) into a 100mL round-bottom flask, protect it with argon, and wait until it is completely dissolved Then add 6.5436 g (0.03 mol) of pyromellitic dianhydride (PMDA), and continue stirring at room temperature for 12 hours to obtain...

Embodiment 2

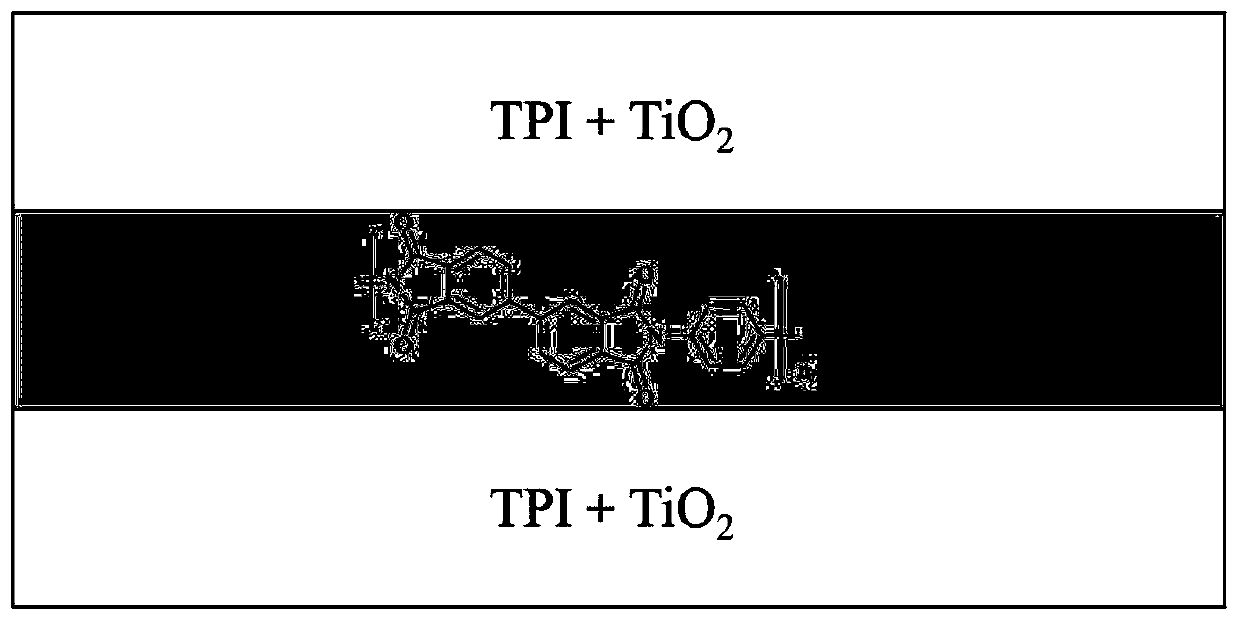

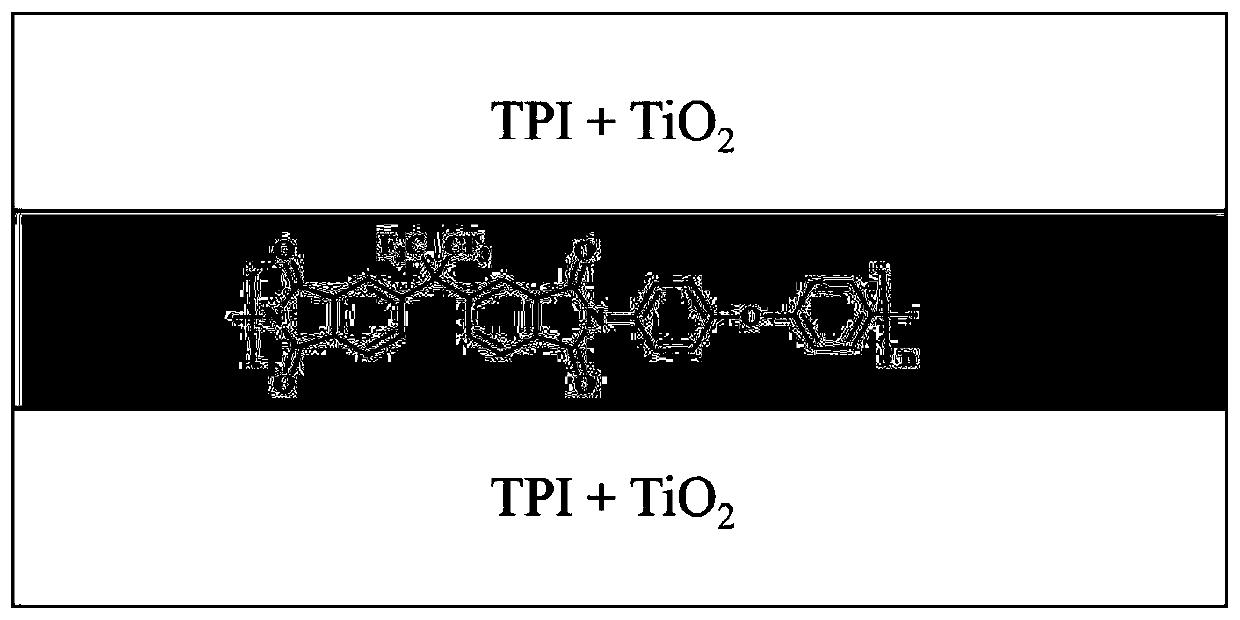

[0049] The schematic diagram of the polyimide film PI212 in the present embodiment 2 is as shown in PI111, and preparation method is as follows:

[0050] (1) Preparation of glue solution PI-1.2

[0051] Weigh TiO 2 5.0g into a round bottom flask, add solvent N,N-dimethylacetamide (DMAc) 80.0g, ultrasonically stir for 1h, then protect with argon, and add 15.0g of soluble PI, continue stirring at room temperature for 5h , to obtain transparent, homogeneous and viscous white transparent polyimide glue PI-1.2.

[0052] Steps (2) to (4) are consistent with those in Example 1 to obtain a white polyimide composite film PI212.

[0053] The test results of PI212 white polyimide composite film are as follows: the tensile strength of PI212 is 95.0 MPa, the elongation at break is 12.3%, the L value is 96.2, and the b value is 4.3.

Embodiment 3

[0055] The schematic diagram of the polyimide film PI313 in the present embodiment 3 is as shown in PI111, and preparation method is as follows:

[0056] (1) Preparation of glue solution PI-1.3

[0057] Weigh TiO 2 10.0g into a round bottom flask, add solvent N,N-dimethylacetamide (DMAc) 80.0g, ultrasonically stir for 1h, then protect with argon, and add soluble PI 10.0g, keep stirring at room temperature for 5h , to obtain transparent, homogeneous and viscous white transparent polyimide glue PI-1.3.

[0058] Steps (2) to (4) are consistent with those in Example 1 to obtain a white polyimide composite film PI313.

[0059] The test results of PI313 white polyimide composite film are as follows: the tensile strength of PI313 is 80.7MPa, the elongation at break is 5.2%, the L value is 98.3, and the b value is 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com