Dual-fuel pressure combustion type four-stroke engine based on reformed gas and combustion control method

A four-stroke engine and control method technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve problems such as difficult reliable control, small working range, and difficulty in meeting the needs of diversified energy sources, and achieve high efficiency and cleanliness Combustion, the effect of optimizing the energy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

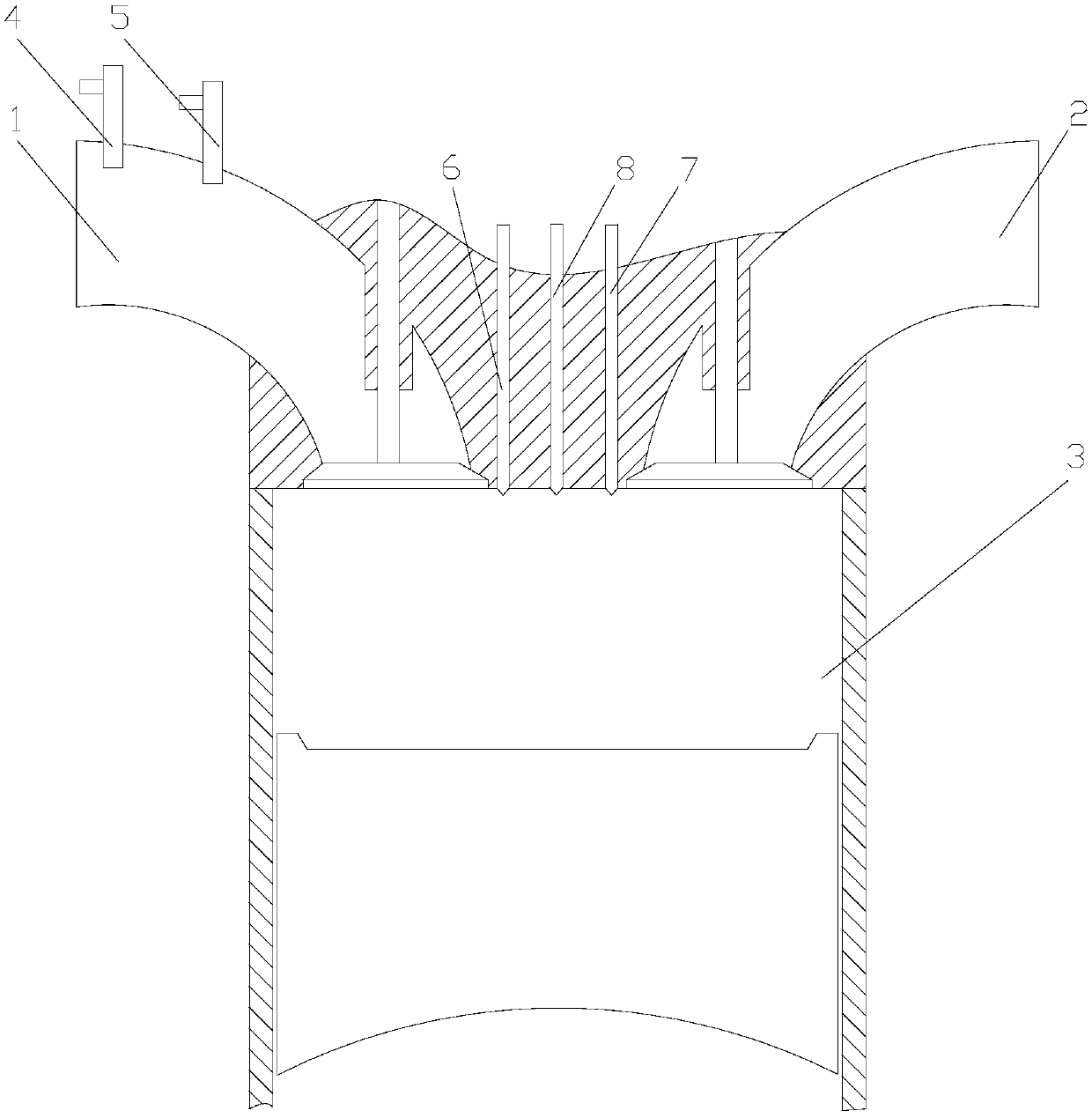

[0030] Example 1, such as figure 1 As shown, the engine includes an intake port 1, an exhaust port 2 and a combustion chamber 3, and a first fuel nozzle 6 for in-cylinder direct injection is arranged on the cylinder head and / or an intake air is arranged on the intake port 1. The first fuel nozzle 5 is installed on the cylinder head, and the second fuel nozzle 7 for in-cylinder direct injection is arranged on the cylinder head. The in-cylinder direct injection reformed gas nozzle 8 is arranged on the cylinder head and / or the intake air Road reformed gas nozzle 4. The ignition mode of the engine is to trigger the fuel combustion in the cylinder by the injection flow of the second fuel nozzle 7 directly injected into the cylinder.

[0031] The bottom of the cylinder head, the bottom of the valve, the top surface of the piston and the fire bank, and the upper part of the cylinder liner that the piston ring cannot touch are sprayed with a heat-insulating coating and / or the piston ...

Embodiment 2

[0039] Embodiment 2 is different from Embodiment 1 in that the number of first fuel nozzles 5 in the intake port is reduced, and by changing the injection timing and injection times of the first fuel nozzle 6 for in-cylinder direct injection, it is mixed with the reformed gas to achieve high efficiency. Clean split combustion.

Embodiment 3

[0040] Embodiment 3 is different from Embodiment 1 in that the first fuel nozzle 6 for in-cylinder direct injection is reduced, and the first fuel is injected through the first fuel nozzle 5 in the intake port, and mixed with reformed gas for combustion to achieve efficient and clean combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com