A kind of metal ion assisted non-nitric acid polishing method

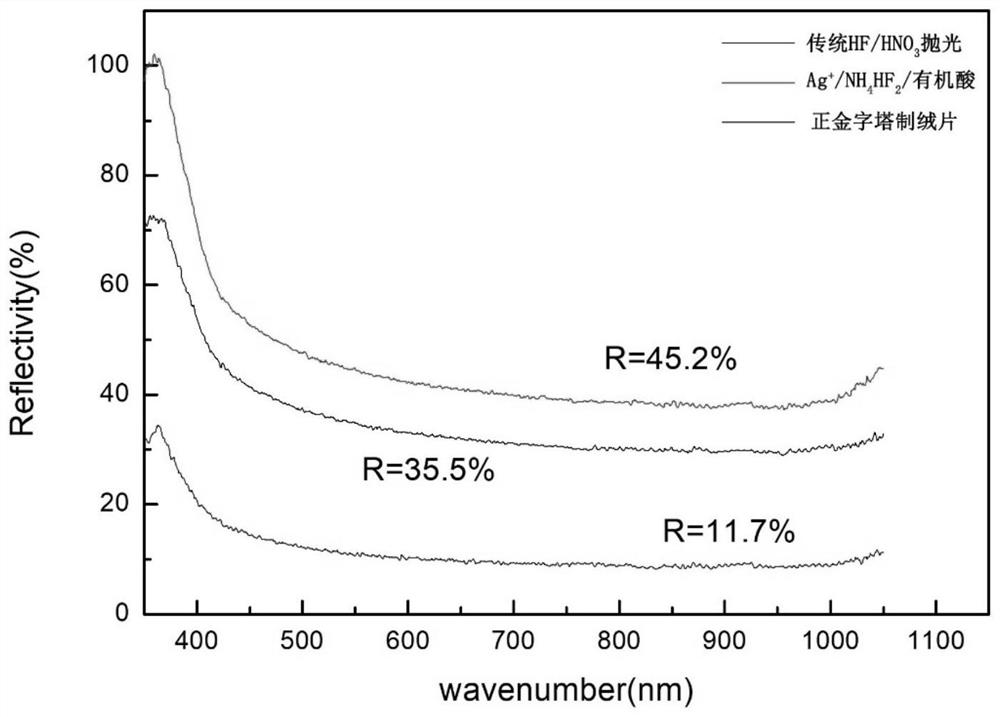

A metal ion-assisted, nitric acid technology, applied in chemical instruments and methods, photovoltaic power generation, sustainable manufacturing/processing, etc., can solve the problems of low reflectivity, large consumption, poor stability, etc., and achieve improved reflectivity, polishing fluid The effect of less consumption and safe and stable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

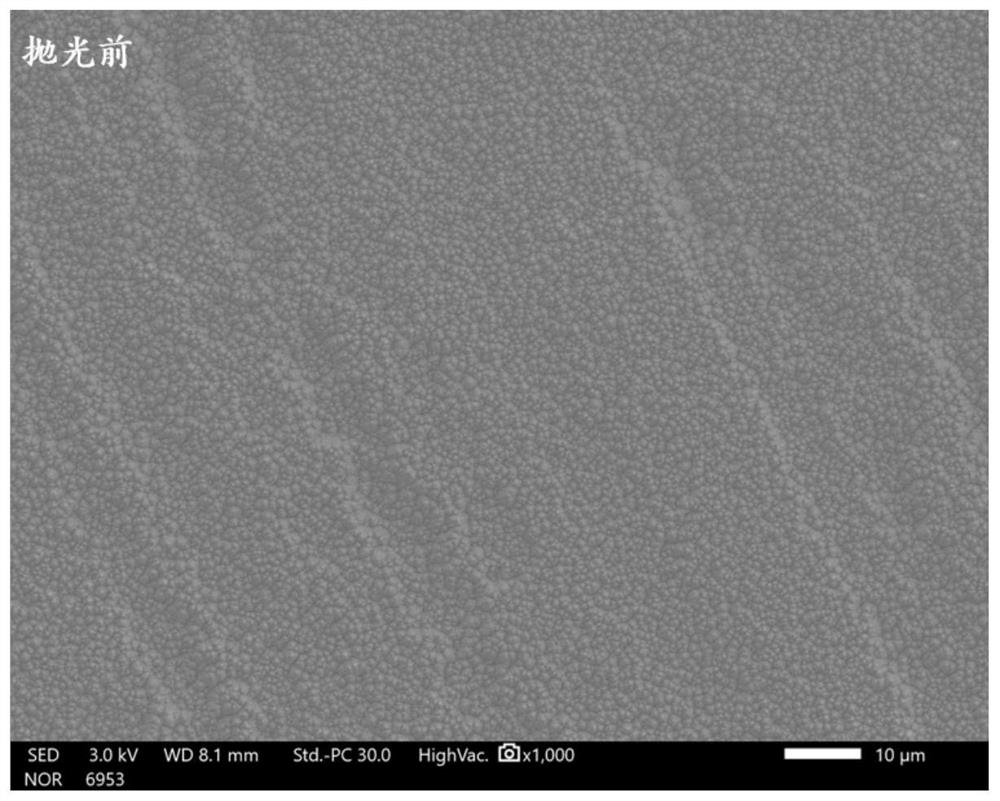

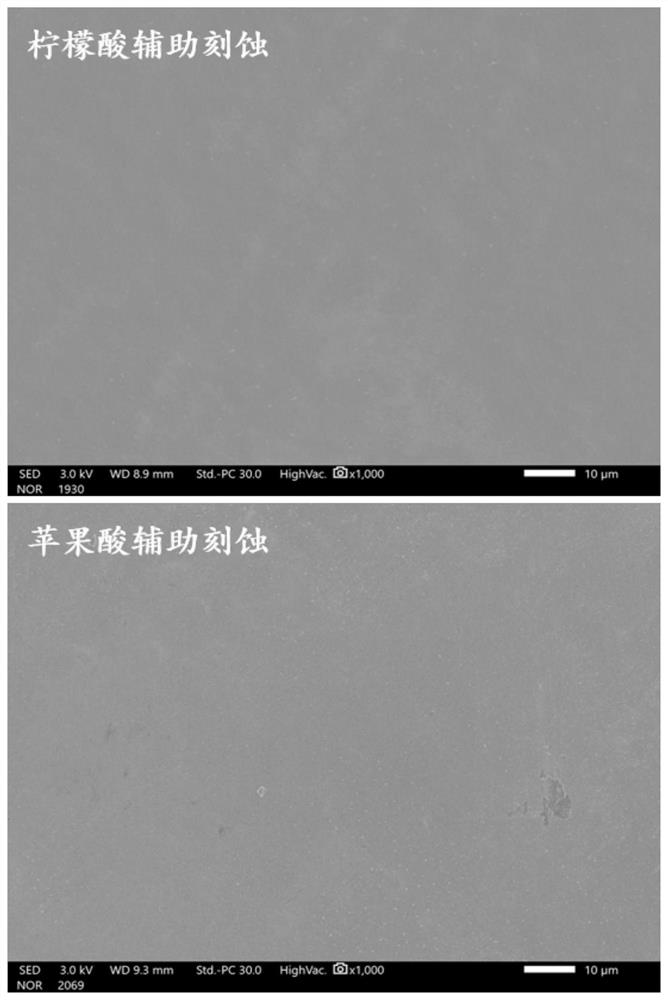

[0020] see Figure 1-3 , a metal ion-assisted non-nitric acid polishing method, comprising the following steps:

[0021] S1: Prepare polishing solution: dissolve 0.5% citric acid, 3ml / L silver nitrate solution, 2% ammonium bifluoride, and 30% hydrogen peroxide into the remaining amount of deionized water in turn, and mix well. The HF2 in ammonium bifluoride has Faster etching rate, while citric acid has a good metal ion chelation effect, and the hydroxyl group on the α carbon is relatively active under the joint action of the adjacent three carboxyl groups, has strong reducibility and is easily soluble in Water, suitable for acidic environment, the combination of the two is ideal in the polishing process;

[0022] S2: heating and polishing: heating the polishing solution obtained in S1 to 65°C, putting the single crystal textured piece into the polishing solution for polishing, and the polishing time is within 150s;

[0023] S3: Cleaning: cleaning the single crystal textured...

Embodiment 2

[0025] see Figure 1-3 , a metal ion-assisted non-nitric acid polishing method, comprising the following steps:

[0026] S1: Prepare polishing solution: dissolve 0.5% citric acid, 3ml / L silver nitrate solution, 2% ammonium bifluoride, and 30% hydrogen peroxide into the remaining deionized water in turn, and mix well;

[0027] S2: heating and polishing: heating the polishing solution obtained in S1 to 65°C, putting the single crystal textured piece into the polishing solution for polishing, and the polishing time is within 150s;

[0028] S3: Cleaning: cleaning the single crystal textured sheet polished in S2.

Embodiment 3

[0030] see Figure 1-3 , a metal ion-assisted non-nitric acid polishing method, comprising the following steps:

[0031] S1: Prepare polishing solution: dissolve 0.5% glycolic acid, 3ml / L silver nitrate solution, 2% ammonium bifluoride, and 30% hydrogen peroxide into the remaining deionized water in turn, and mix well;

[0032] S2: heating and polishing: heating the polishing solution obtained in S1 to 65°C, putting the single crystal textured piece into the polishing solution for polishing, and the polishing time is within 150s;

[0033] S3: Cleaning: cleaning the single crystal textured sheet polished in S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com