Ceramic-polymer composites obtained by cold sintering process using reactive monomer approach

A reactive oligomer, sintered ceramic technology, applied in ceramic products, applications, household appliances, etc., can solve problems such as increasing the cost of manufacturing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

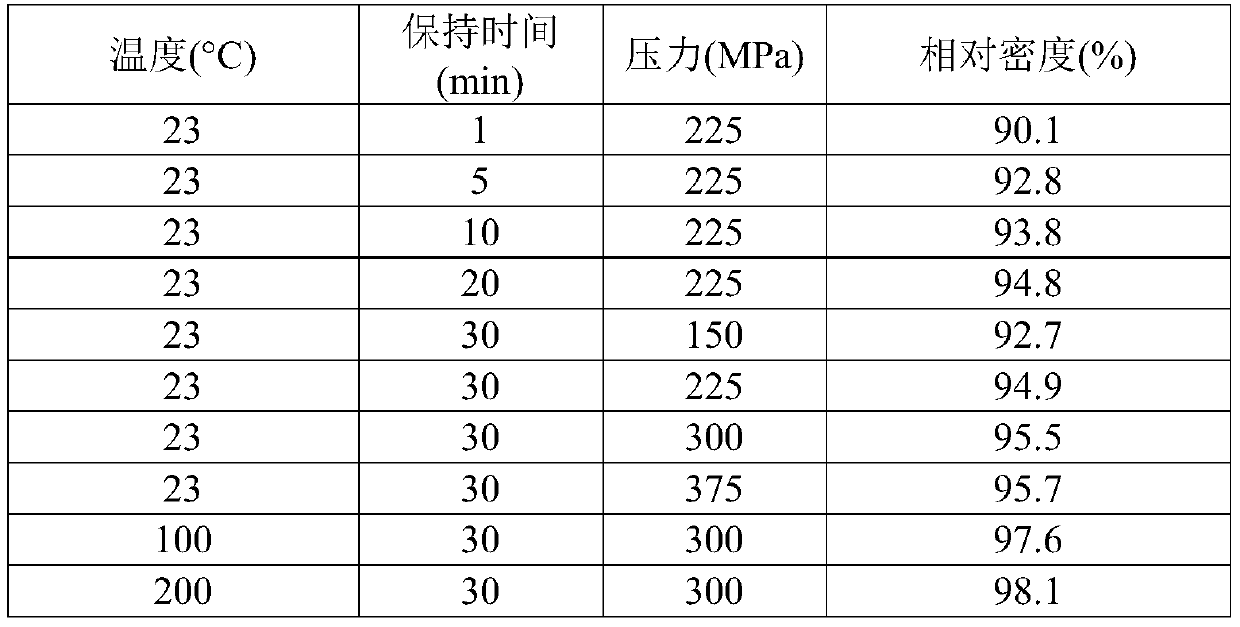

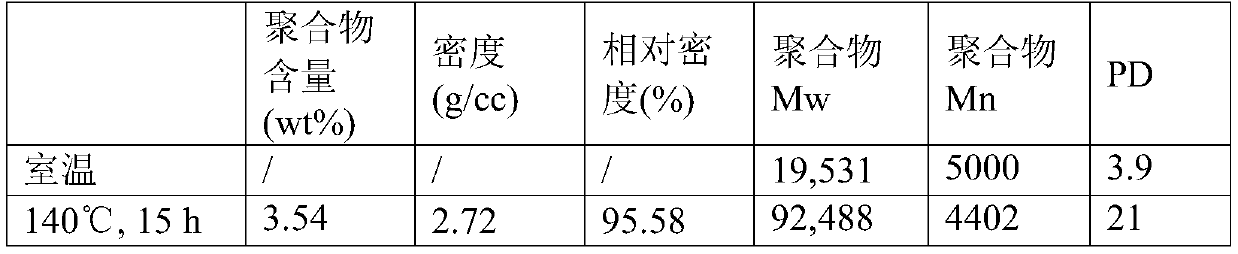

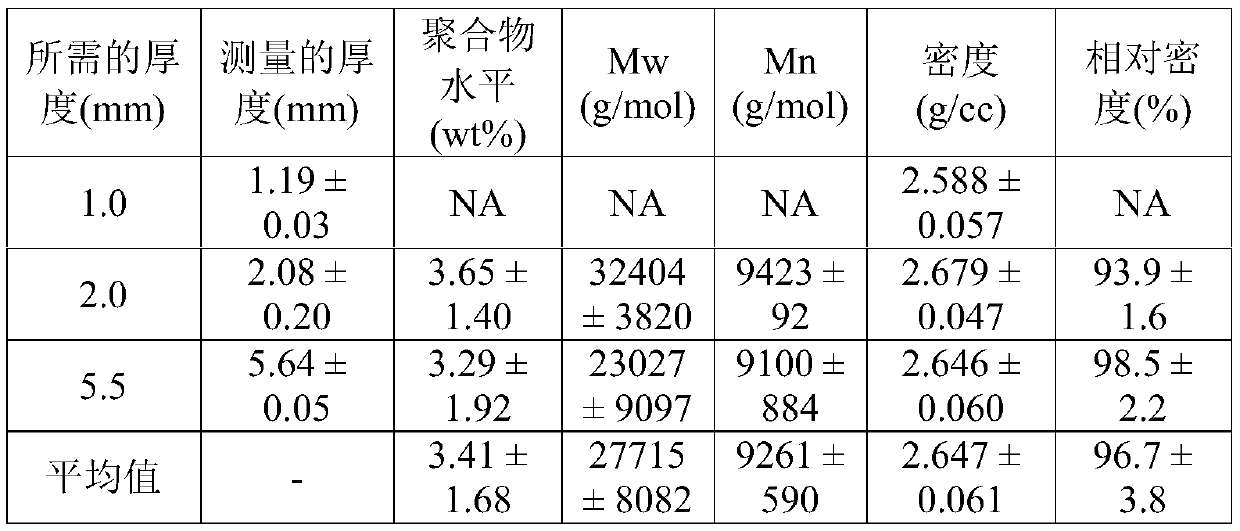

Examples

Embodiment 1

[0099] The powdered MoO 3 Mixed with monomers such as acrylates or cyclic ethers. To the resulting mixture was added deionized water or alcohol solvent (1-2 wt%).

[0100] Alternatively, the monomers are first dissolved in one or more organic solvents and then mixed with MoO 3 Powder blending. The solvent or solvent mixture is then removed, after which water (1-2 wt%) is introduced prior to sintering.

[0101] The mixture was stirred in a mortar and pestle and then hot pressed with a steel die at 120°C under uniaxial pressure of about 50-600 MPa into dense pellets (~10 mm in diameter and ~1-2 mm in height) ). The cold sintering process is carried out simultaneously with the polymerization, or the polymerization is initiated before the cold sintering process. The mold was kept at 120°C for more than 1 hour. Finally, the pellets of cold sintered ceramic polymer composite were removed and placed in an oven at 120°C for 6 hours to remove any residual water.

Embodiment 2

[0103] The powdered MoO 3 Mix with deionized water or alcohol (1-2 wt%) to obtain a mixture. The mixture was stirred in a mortar and pestle, and the moist mixture was hot pressed into dense pellets (~10 mm in diameter and ~1-2 mm in height) with a steel die at 120°C under uniaxial pressure of about 50-600 MPa. The mold was kept at 120°C for more than 1 hour. The resulting pre-sintered ceramic is mixed with monomers such as acrylates or cyclic ethers, and the monomers are polymerized, optionally in the presence of a polymerization catalyst. The resulting pellets were placed in an oven at 120°C for 6 hours to remove any traces of water residues, resulting in a cold sintered ceramic polymer composite.

Embodiment 3

[0105] The powdered MoO 3 Mixed with reactive monomers such as acrylates or cyclic ethers, then pressed into soft pellets at room temperature under low pressure (30-70 MPa). The pellets are then exposed to a humid atmosphere (eg, water vapor generated by heating deionized water or in a humidity chamber) for 10-360 minutes. Then, at a temperature of 120° C. and a uniaxial pressure of 80-570 MPa, the wet pellets are hot-pressed into dense pellets with a steel die. The mold was kept at 120°C for more than 1 hour. Finally, the pellets were placed in an oven at 120° C. for 6 hours to remove any water residues, resulting in a cold sintered ceramic polymer composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com