Modified composite barite for drilling fluid

A barite and drilling fluid technology, applied in the field of drilling fluid, can solve the problems of easy separation and settlement at the bottom of the circulating tank, increase of mud specific gravity, increase of drilling fluid friction, etc., to improve hydrophilic dispersion performance and reduce internal friction Resistance, effect of increasing zeta potential value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

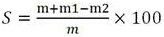

Method used

Image

Examples

Embodiment 1

[0026] 40 parts of barite from 500 mesh to 800 mesh, 60 parts of barite from 400 mesh to 600 mesh, sodium hexametaphosphate is 0.5% of the weight of composite barite powder, and acrylic copolymer is the weight of composite barite powder 0.025% of the weight of the composite barite powder, octylphenol ethoxylate-30 is 0.03% of the weight of the composite barite powder, and polyethylene glycol 400 is 0.02% of the weight of the composite barite powder.

[0027] A preparation method of modified composite barite for drilling fluid, comprising the steps of:

[0028] (1) Take barite and barite and put them into the mixer, and stir for 20 minutes to obtain composite barite. Add sodium hexametaphosphate to the composite barite while stirring, and use a dry modification process to make sodium hexametaphosphate Coated on the surface of composite barite powder, the barite must be coated for later use;

[0029] (2) Preparation of acrylic copolymer: Weigh a certain amount of phthalic anhyd...

Embodiment 2

[0033] 50 parts of barite from 500 mesh to 800 mesh, 50 parts of barite from 400 mesh to 600 mesh, sodium hexametaphosphate is 0.8% of the weight of composite barite powder, and acrylic copolymer is the weight of composite barite powder 0.05%, octylphenol polyoxyethylene ether-30 is 0.06% of the weight of the composite barite powder, and polyethylene glycol 400 is 0.04% of the weight of the composite barite powder.

[0034] A preparation method of modified composite barite for drilling fluid, comprising the steps of:

[0035](1) Take barite and barite and put them into the mixer, and stir for 20 minutes to obtain composite barite. Add sodium hexametaphosphate to the composite barite while stirring, and use a dry modification process to make sodium hexametaphosphate Coated on the surface of composite barite powder, the barite must be coated for later use;

[0036] (2) Preparation of acrylic copolymer: Weigh a certain amount of phthalic anhydride and n-butanol and place it in a...

Embodiment 3

[0040] 45 parts of barite from 500 mesh to 800 mesh, 55 parts of barite from 400 mesh to 600 mesh, sodium hexametaphosphate is 0.6% of the weight of composite barite powder, acrylic copolymer is the weight of composite barite powder 0.04%, octylphenol polyoxyethylene ether-30 is 0.05% of the weight of the composite barite powder, and polyethylene glycol 400 is 0.03% of the weight of the composite barite powder.

[0041] A preparation method of modified composite barite for drilling fluid, comprising the steps of:

[0042] (1) Take barite and barite and put them into the mixer, and stir for 20 minutes to obtain composite barite. Add sodium hexametaphosphate to the composite barite while stirring, and use a dry modification process to make sodium hexametaphosphate Coated on the surface of composite barite powder, the barite must be coated for later use;

[0043] (2) Preparation of acrylic copolymer: Weigh a certain amount of phthalic anhydride and n-butanol and place it in a fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com