Method suitable for independent smelting of various types of complex gold concentrate

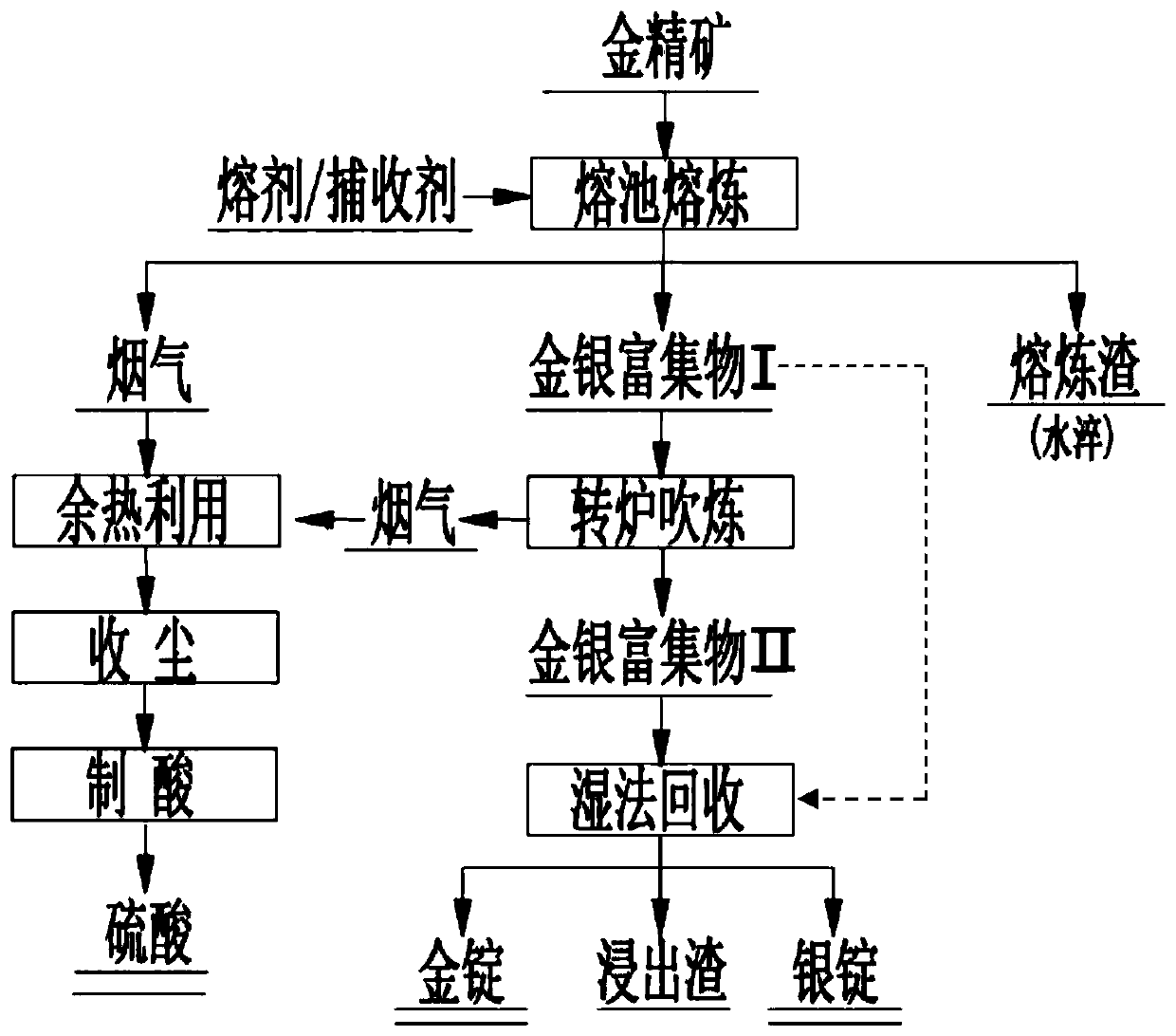

A gold concentrate and complex technology, which is applied in the field of independent smelting of various types of complex gold concentrates, can solve the problems of increased smelting costs, unsuitable treatment of gold concentrates, and inability to realize separate treatment of gold concentrates, so as to reduce smoke and dust production High yield, easy industrialization, and efficient comprehensive recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The main components of gold concentrate are Au 18.32g / t, Ag 70g / t, Cu 3.72%, S 26%, Fe 22%, adding quartz, limestone, coke powder, etc. The material ratio is: gold concentrate:quartz:limestone : coke powder = 100:1:1:4.5, sent to the smelting furnace for smelting, controlled reaction temperature 1200~1350°C, oxygen concentration 70%, output flue gas SO 2 The concentration is 17%, and it is sent to the acid system after dust collection, and the dust rate is about 1.5%. The grades of gold and silver in matte reached 149.6g / t and 554.17g / t respectively, the grade of iron was 30.6%, and the grade of copper was 29.45%. Put the matte into a 9% quartz converter for oxygen-enriched blowing, and control the reaction temperature at 1300-1350°C. The grades of gold and silver in the produced gold and silver enrichment II reach 4895.68g / t and 18133.57g / t respectively. The enrichment is electrolyzed to recover copper, gold and silver enter into anode slime, and produce gold and silv...

Embodiment 2

[0028] The main components of gold-bearing smelting slag are Au 15.65g / t, Ag 1.5g / t, S 3.2%, Fe 5%, adding pyrite, quartz, coal powder for oxygen-enriched smelting, gold-bearing smelting slag, pyrite, The quartz ratio is 100:50:10, the reaction temperature is controlled at about 1350°C, the oxygen concentration is 75%, and the flue gas SO is produced 2 The concentration is 12%, and it is sent to the acid system after dust collection, and the dust rate is about 1.5%. The grades of gold and silver in matte reached 125.20g / t and 7.50g / t respectively, and the grade of iron was 56.3%. The gold-silver-rich matte is finely ground and leached with oxygen-enriched sulfuric acid, iron and sulfur are leached into the solution, gold and silver are enriched in the slag, and gold and silver can be directly extracted by hydrometallurgy. The gold recovery rate is greater than 97.5%, and the silver recovery rate is greater than 60%.

Embodiment 3

[0030]The main components of gold concentrate produced by beneficiation are Au 41g / t, Ag 28g / t, S 21.42%, Fe 23%, SiO 2 20%, add 5% pyrite and 5% coal powder, carry out oxygen-enriched smelting, control the reaction temperature at about 1350°C, the gold and silver grades in the matte reach 1010.5g / t and 594.8g / t respectively, and the Fe grade 60.2%, gold and silver can be directly recovered by hydrometallurgical extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com