Aluminum-clad composite core wire cable and production process thereof

A wire cable and composite core technology, which is applied in the field of power cables, can solve problems such as accidents in operation, large bending diameters, and sharp-angle bending, and achieve the effects of increasing ratio, increasing flexibility, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

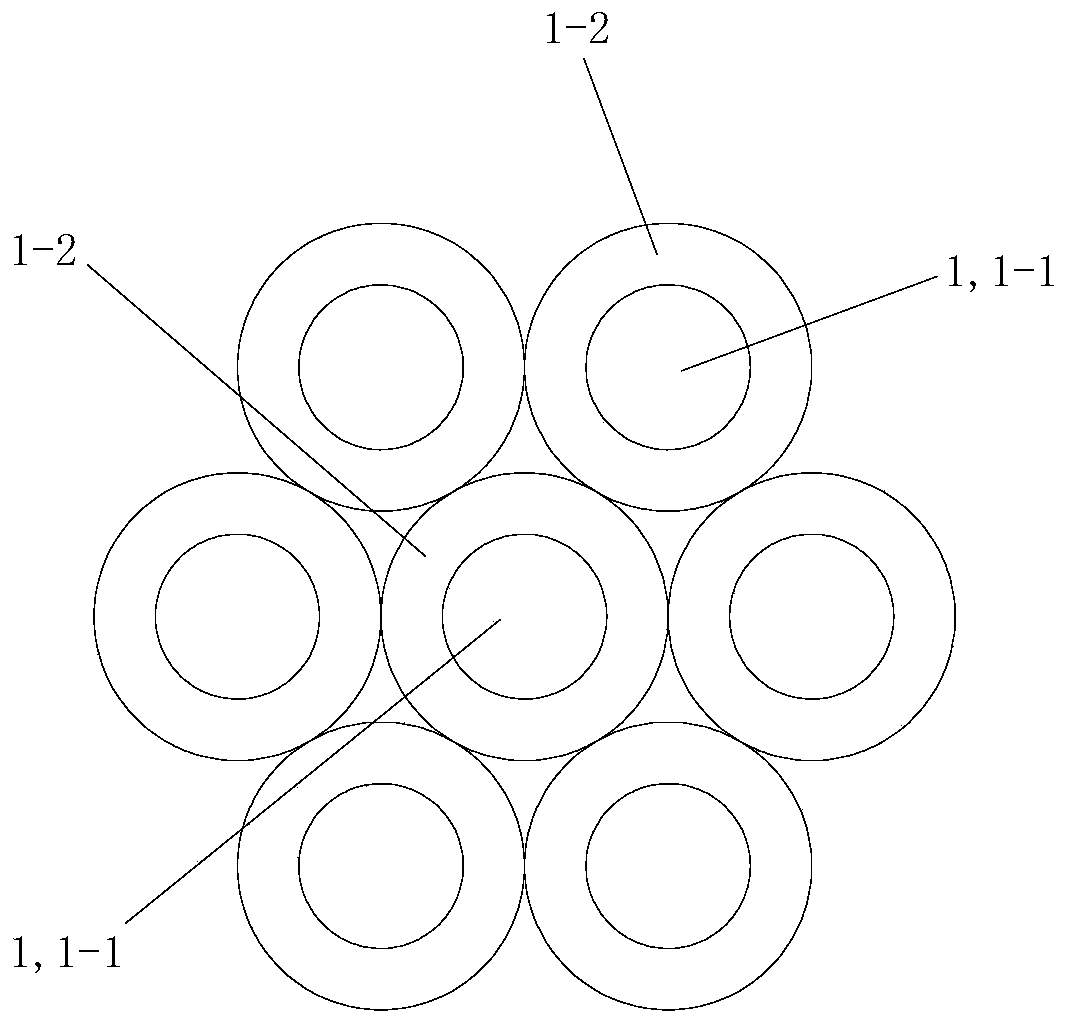

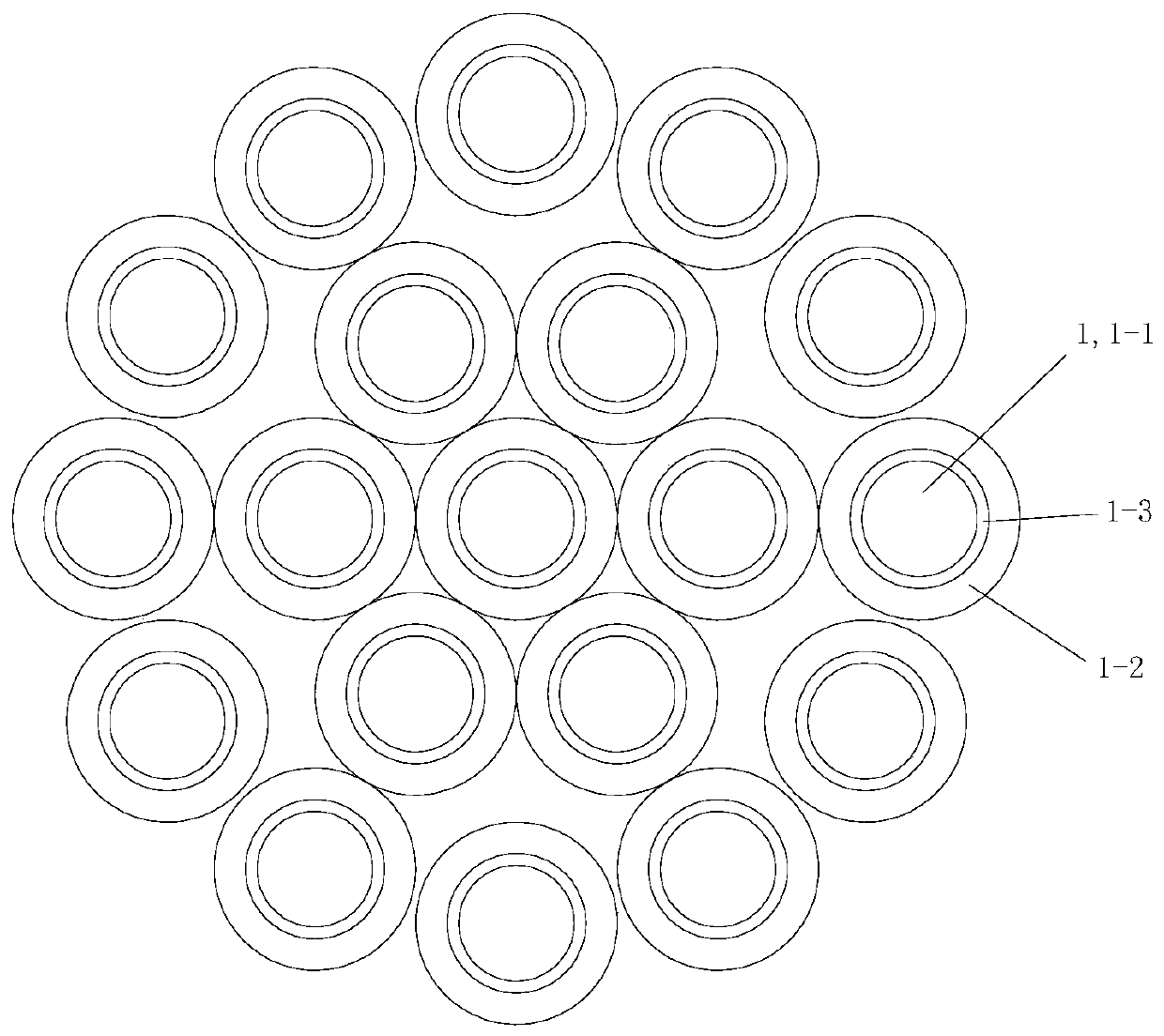

[0042] See figure 1 , the aluminum-clad composite core wire cable of the present invention includes 7 or 19 or 37 aluminum-clad composite core wires 1, and the 7 aluminum-clad composite core wires 1 are normally twisted into a composite core wire cable with a 1+6 structure; 19 aluminum-coated composite core conductors 1 adopt a 1+6+12 structure to form a composite core conductor cable; 37 aluminum-coated composite core conductors 1 adopt a 1+6+12+18 structure to form a composite core conductor cable. The pitch diameter ratio of the stranded cable is 10 to 30, and the pitch diameter ratio of the outer layer is not greater than the pitch diameter ratio of the inner layer.

[0043] The aluminum-clad composite core wire cable in this embodiment is composed of seven composite core wires 1 that are normally stranded in a 1+6 structure. The aluminum clad composite core wire 1 includes a wire core 1-1 and an aluminum cladding layer 1-2. The diameter of the wire core 1-1 is 1.0 to 5....

Embodiment 2

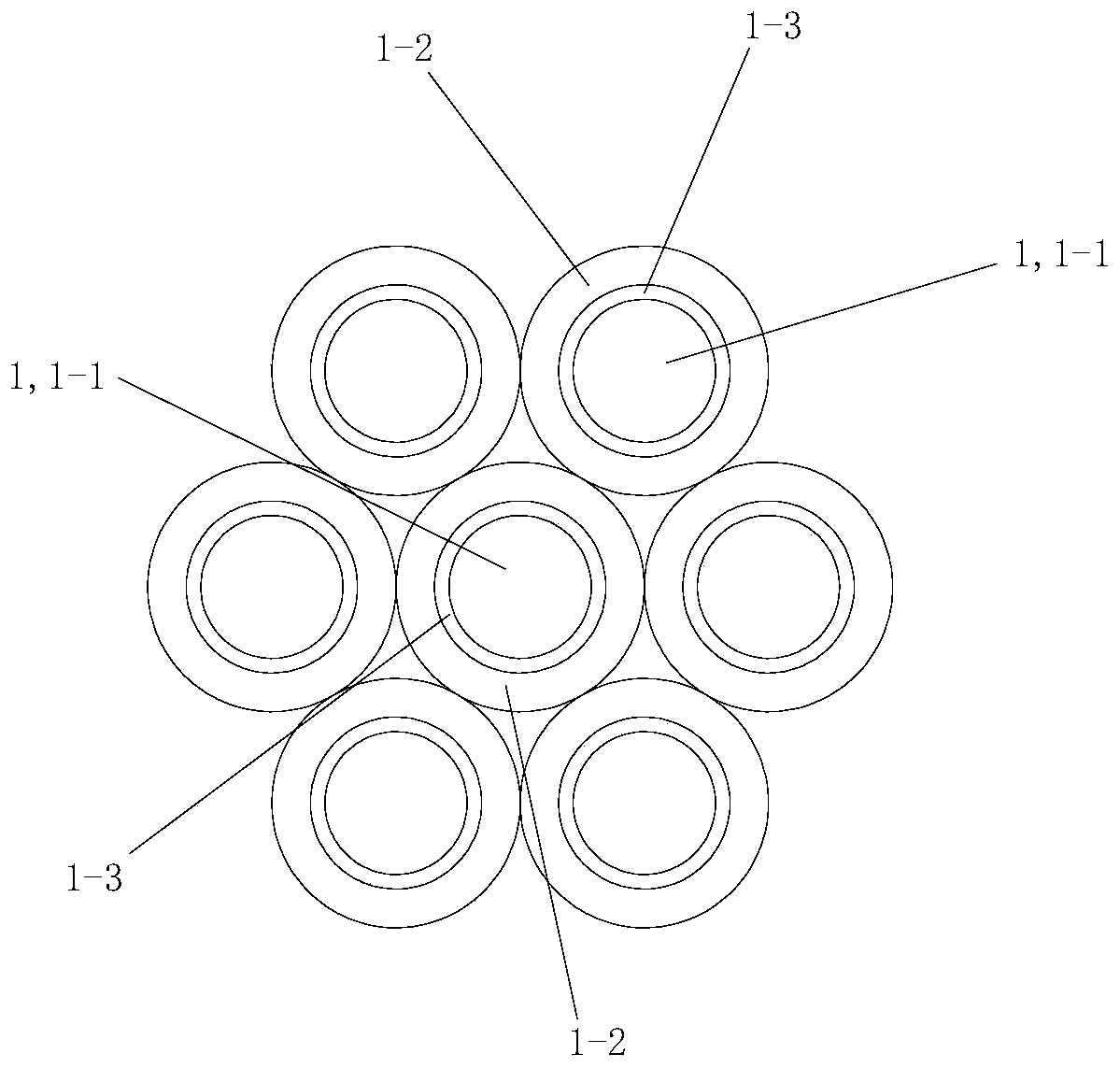

[0047] See figure 2 and image 3 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: an adhesive layer 1-3 is also included. The matrix of the wire core 1-1 is made of thermosetting resin such as phenolic resin, unsaturated polyester, epoxy resin or thermoplastic resin such as polyphenylene sulfide.

[0048] Adhesive layer 1-3 is made of polyether ether ketone resin material, polyether ether ketone resin is coated on the outside of wire core 1-1 by extrusion process, aluminum cladding layer 1-2 is coated on adhesive layer 1-3 The outside is in direct contact with the adhesive layer 1-3 to form an adhesive fixed connection. The thickness of the adhesive layer 1-3 is 0.2 mm to 1.0 mm.

Embodiment 3

[0050] The rest of this embodiment is the same as that of Embodiment 2, except that the adhesive layer 1-3 is made by using continuous fiber as a reinforcement and polyether ether ketone resin as a matrix through a thermoplastic pultrusion process. The fiber body adopts continuous fibers such as carbon fiber, glass fiber, basalt fiber or aramid fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com